Premium Only Content

The Steel Making Process From Start to Finish - Material Science

RCast iron pan manufacturing process

RMaking a Caterpillar Engine Block at the Mapleton, IL Foundry

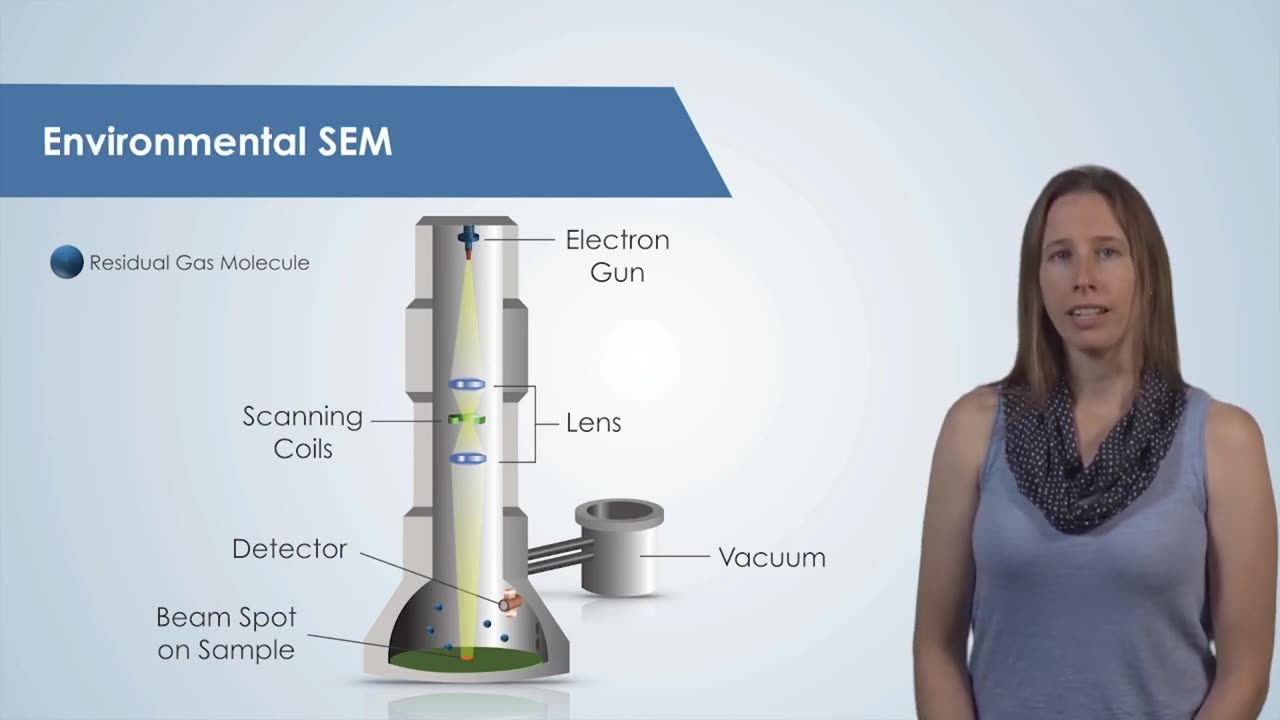

RIntroduction to the Scanning Electron Microscope (SEM)

Magnetic Particle Inspection: Material Science

Vickers Hardness Test - Material Science

Metallography - Macroscopic Techniques - Material Science

Dye Penetrant Inspection - Material Science

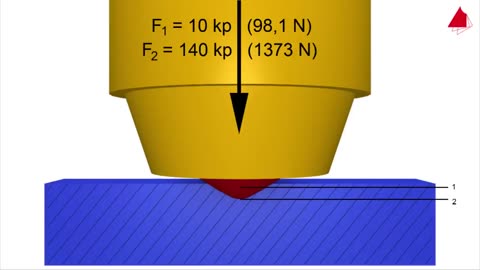

Brinell Hardness Test - Material Science

Rockwell Hardness Test: Material Science

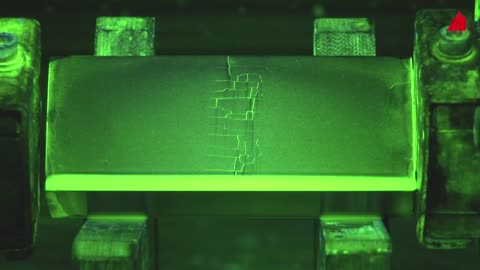

Fatigue Test - Material Science

Material Science: Eddy Current Testing

Tensile Test: Material Science

The Scanning Electron Microscope: Material Science

Microscopic Techniques - Metallography - Material Science

Material Science: X-ray Inspection and Industrial Computed Tomography

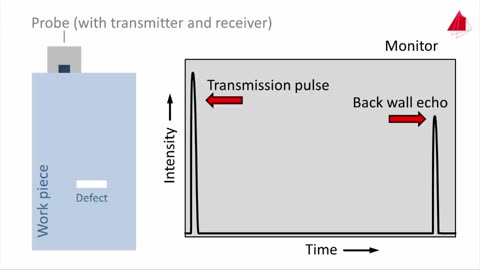

Ultrasonic Testing Basics: Material Science NDT

Introduction to the Scanning Electron Microscope (SEM)

Introduction to the Scanning Electron Microscope (SEM)

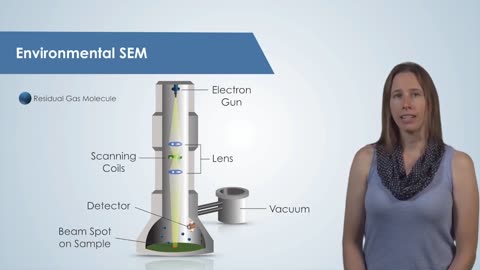

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the surface topography and composition of the sample. The electron beam is scanned in a raster scan pattern, and the position of the beam is combined with the intensity of the detected signal to produce an image. In the most common SEM mode, secondary electrons emitted by atoms excited by the electron beam are detected using a secondary electron detector (Everhart–Thornley detector). The number of secondary electrons that can be detected, and thus the signal intensity, depends, among other things, on specimen topography. Some SEMs can achieve resolutions better than 1 nanometer.

More Material Science Videos

https://rumble.com/playlists/QExVxeOAGck

-

DVR

DVR

TheAlecLaceShow

4 hours agoDoes Racism Exist? Guest: Franck Zanu | Elon’s Viral Meme | Hunter Pardon | The Alec Lace Show

5.07K3 -

LIVE

LIVE

G2G Gaming Channel

6 hours agoI heard Smite, So Im here! #RumbleTakeOver #RumbleGaming

120 watching -

15:36

15:36

Neil McCoy-Ward

2 hours ago🚨 Emergency Martial Law Declared, Special Forces Deployed...

12.7K5 -

1:57:30

1:57:30

The Charlie Kirk Show

2 hours agoDemocrat Billionaires in Crisis + Fixing the Migrant Crisis | Blagojevich, O'Brien, Metaxas| 12.3.24

51.5K11 -

1:01:07

1:01:07

The Dan Bongino Show

5 hours agoBiden’s Reign Of Destruction Isn’t Over Yet (Ep. 2381) - 12/03/2024

611K1.51K -

1:59:02

1:59:02

Steven Crowder

5 hours ago🔴 COVID Chronicles: The Hidden Truths of the Pandemic Exposed

336K200 -

LIVE

LIVE

SoundBoardLord

4 hours agoMulti-Gen Don Juan in Full Force!

168 watching -

1:08:54

1:08:54

MTNTOUGH Fitness Lab

4 hours agoSheriff Mark Lamb Exposes America’s Border Crisis and Cartel Infiltration | MTNT POD#93

8.75K1 -

8:52

8:52

Cooking with Gruel

12 hours agoToasted Brown Butter Cornbread

10.8K -

1:01:44

1:01:44

The Rubin Report

3 hours agoJon Stewart Loses His Cool with Democrats for Saying This About Hunter Biden Pardon

49.7K60