Material Science

17 videos

Updated 8 months ago

Materials science and engineering seeks to understand the fundamental physical origins of material behavior in order to optimize properties of existing materials through structure modification and processing, design and invent new and better materials, and understand why some materials unexpectedly fail

-

The Steel Making Process From Start to Finish - Material Science

RRumblestuffThe Steel Making Process From Start to Finish Steel is an alloy of iron and carbon with improved strength and fracture resistance compared to other forms of iron. Because of its high tensile strength and low cost, steel is one of the most commonly manufactured materials in the world. Steel is used in buildings, as concrete reinforcing rods, in bridges, infrastructure, tools, ships, trains, cars, bicycles, machines, electrical appliances, furniture, and weapons. Iron is always the main element in steel, but many other elements may be present or added. Stainless steels, which are resistant to corrosion and oxidation, typically need an additional 11% chromium. Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides. The first blast furnaces appeared in the 14th century and produced one ton per day. Even though equipment is improved and higher production rates can be achieved, the processes inside the blast furnace remain the same. The blast furnace uses coke, iron ore and limestone to produce pig iron. Coal traditionally has been a key part of the coke-making process. The coal is crushed and ground into a powder and then charged into an oven where it is heated to approximately 1800°F in the absence of oxygen. As the oven is heated, the coal begins to melt so most of the volatile matter such as oil, tar, hydrogen, nitrogen and sulfur are removed. The cooked coal, called coke, is removed from the oven after 18 to 24 hours of reaction time. The coke is cooled and screened into pieces ranging from one inch to four inches. The coke is a porous, hard black rock of concentrated carbon (contains 90 to 93 percent carbon), which has some ash and sulfur but compared to raw coal is very strong. The strong pieces of coke with a high energy value provide permeability, heat and gases which are required to reduce and melt the iron ore, pellets and sinter. Today, natural gas is increasingly being added in place of coke to the same degree in the blast furnace to reduce carbon emissions https://www.steel.org/steel-technology/steel-production/302 views 1 comment -

Cast iron pan manufacturing process

RRumblestuffCast iron pan manufacturing process. Metal foundry in South Korea274 views -

Making a Caterpillar Engine Block at the Mapleton, IL Foundry

RRumblestuffWatch how employees at the Caterpillar Foundry in Mapleton, Illinois, turn recycled scrap into high-strength cast iron blocks for Caterpillar engines.1.73K views 3 comments -

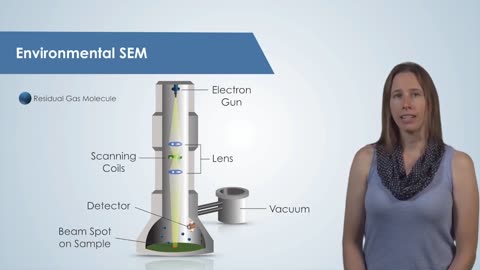

Introduction to the Scanning Electron Microscope (SEM)

F5TornadoIntroduction to the Scanning Electron Microscope (SEM) A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the surface topography and composition of the sample. The electron beam is scanned in a raster scan pattern, and the position of the beam is combined with the intensity of the detected signal to produce an image. In the most common SEM mode, secondary electrons emitted by atoms excited by the electron beam are detected using a secondary electron detector (Everhart–Thornley detector). The number of secondary electrons that can be detected, and thus the signal intensity, depends, among other things, on specimen topography. Some SEMs can achieve resolutions better than 1 nanometer. More Material Science Videos https://rumble.com/playlists/QExVxeOAGck123 views 1 comment

F5TornadoIntroduction to the Scanning Electron Microscope (SEM) A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the surface topography and composition of the sample. The electron beam is scanned in a raster scan pattern, and the position of the beam is combined with the intensity of the detected signal to produce an image. In the most common SEM mode, secondary electrons emitted by atoms excited by the electron beam are detected using a secondary electron detector (Everhart–Thornley detector). The number of secondary electrons that can be detected, and thus the signal intensity, depends, among other things, on specimen topography. Some SEMs can achieve resolutions better than 1 nanometer. More Material Science Videos https://rumble.com/playlists/QExVxeOAGck123 views 1 comment -

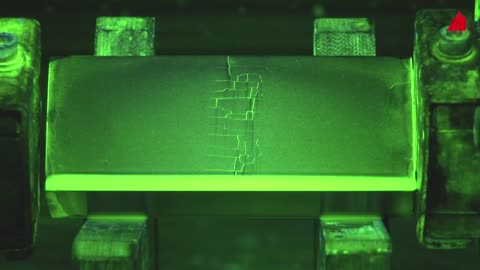

Magnetic Particle Inspection: Material Science

F5TornadoNondestructive Testing - Magnetic Particle Inspection - Basic principle - Preconditions - Practical Procedure More Material Science Videos https://rumble.com/playlists/QExVxeOAGck169 views

F5TornadoNondestructive Testing - Magnetic Particle Inspection - Basic principle - Preconditions - Practical Procedure More Material Science Videos https://rumble.com/playlists/QExVxeOAGck169 views -

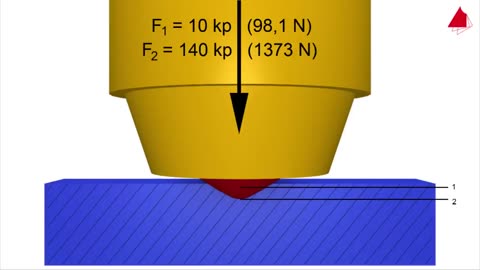

Vickers Hardness Test - Material Science

F5TornadoBasic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness definition and practical procedure value More Material Science Videos https://rumble.com/playlists/QExVxeOAGck65 views

F5TornadoBasic principle and practical procedure of the Vickers hardness test - Testing machine, test piece, diamond pyramid indenter - Basic principle, hardness definition and practical procedure value More Material Science Videos https://rumble.com/playlists/QExVxeOAGck65 views -

Metallography - Macroscopic Techniques - Material Science

F5TornadoMetallography -- Macroscopic Techniques - Preparation of an ingot and a piston: sawing, grinding and etching - Individual grains are visible - Preparation of several steel specimens: flame hardened tooth of a gear wheel, induction hardened cylindrical shaft, induction hardened splined shaft, case hardened tooth of a gear wheel, weld joint - Weld pass structure and heat treated zones and are visible More Material Science Videos https://rumble.com/playlists/QExVxeOAGck110 views

F5TornadoMetallography -- Macroscopic Techniques - Preparation of an ingot and a piston: sawing, grinding and etching - Individual grains are visible - Preparation of several steel specimens: flame hardened tooth of a gear wheel, induction hardened cylindrical shaft, induction hardened splined shaft, case hardened tooth of a gear wheel, weld joint - Weld pass structure and heat treated zones and are visible More Material Science Videos https://rumble.com/playlists/QExVxeOAGck110 views -

Dye Penetrant Inspection - Material Science

F5TornadoDye Penetrant Inspection - Basic principle - Practical procedure - Pros and cons More Material Science Videos https://rumble.com/playlists/QExVxeOAGck82 views 2 comments

F5TornadoDye Penetrant Inspection - Basic principle - Practical procedure - Pros and cons More Material Science Videos https://rumble.com/playlists/QExVxeOAGck82 views 2 comments -

Brinell Hardness Test - Material Science

F5TornadoBasic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition of the hardness value More Material Science Videos https://rumble.com/playlists/QExVxeOAGck127 views

F5TornadoBasic principle and practical procedure of the Brinell hardness test - Testing machine - Test piece - Spherical indenter - Basic principle - Definition of the hardness value More Material Science Videos https://rumble.com/playlists/QExVxeOAGck127 views -

Rockwell Hardness Test: Material Science

F5TornadoBasic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness definition, testing procedure More Material Science Videos https://rumble.com/playlists/QExVxeOAGck76 views 1 comment

F5TornadoBasic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness definition, testing procedure More Material Science Videos https://rumble.com/playlists/QExVxeOAGck76 views 1 comment