Premium Only Content

LED Dock Light for Hazardous Locations - 50 Watt with 4' Pivoting Arm - 7000 Lumens

The Larson Electronics HAL-DL-60HV-48 Hazardous Location LED Dock Light Fixture with Swing Arm Mount provides operators with a powerful alternative to traditional luminaries in combustible facilities. Capable of replacing 250-watt metal halide lamps, this 50-watt low bay LED unit emits 7,000 lumens, carries an IP67 waterproof rating and features an extended lifespan of 60,000+ hours. The factory sealed, hazardous location fixture is protected by a copper-free aluminum housing with an epoxy powder coated finish. The HAL-DL-60HV-48 is equipped with a 4' swing arm mount.

The HAL-DL-60HV-48 is a Class I, Division 2 and Class II, Divisions 1 & 2 hazardous location light fixture that is designed for energy efficient and superior illumination in combustible environments. This 50-watt low bay fixture offers 7,000 lumens of high quality light with a color temperature of 5600K. We also offer a 3000K warm white and 4500K natural white color temperature options (longer lead times may apply for non-standard temperatures). Serving as a suitable replacement for 250-watt metal halide lamps, a color rendering index of 75 ensures colors and details are produced more accurately than high pressure sodium or mercury vapor luminaries.

This low bay lighting solution for explosive sites is IP67 rated, dust-proof and protected against high pressure jets and temporary submersion. The copper-free aluminum alloy housing is specially designed to dissipate heat which increases the efficiency and lifespan of the LEDs and electronic components. An epoxy powder coated finish facilitates durability and an attractive aesthetic appearance. Special heat dissipating design in conjunction with LED technology helps this fixture to achieve an excellent 60,000-hour rated lifespan with 80% lumen retention. The hazardous location low bay LED light also offers operators convenience in the form of field serviceability.

LED Benefits: Unlike gas burning and arc type lamps that have glass bulbs, LEDs have no filaments or fragile housings to break during operation and/or transportation. Instead of heating a small filament or using a combination of gases to produce light, light emitting diodes (LEDs) use semi-conductive materials that illuminate when electric current is applied, providing instant illumination with no warm up or cool down time before re-striking. Because there is no warm up period, this light can be cycled on and off with no reduction in lamp life.

LED lights run at significantly cooler temperatures than traditional metal halide and high pressure sodium lights and contain no harmful gases, vapors, or mercury, making them both safer and more energy efficient. No extra energy is wasted in cooling enclosed work areas due to external heat emissions from bulb type lights, and the operator risks associated with traditional lighting methods, such as accidental burns and exposure to hazardous substances contained in the glass bulbs, are eliminated. In addition, LEDs are also safer for the environment as they are 100% recyclable, which eliminates the need for costly special disposal services required with traditional gas burning and arc type lamps.

LED Drivers: Even in LED fixtures, heat is the single largest factor in premature light failure and color shifting. As a result, many manufacturers reduce the output of their LEDs in order to reduce the amount of heat produced. Rather than lower light output or quality, Larson Electronics addresses this problem with the addition of an electronic LED driver. This internal driver provides the ability to automatically monitor and adjust input current to maintain the correct LED voltage levels regardless of input levels across a specific range. This not only reduces the energy dissipation, effectively lowering the operating temperature of the fixture, but also prevents AC over-voltage and short circuit loading making this fixture virtually maintenance free. Because the electronic driver allows the HAL-DL-60HV-48 to run at a cooler internal temperature and regulates the electrical current, energy efficiency and LED service hours are maximized while at the same time reducing operating costs and downtime incurred from the frequent servicing intervals required with other hotter running lights.

Click to Subscribe: https://www.youtube.com/channel/UCeaWkKO35T-VYgJ-Jc-bN_g?sub_confirmation=1

-

1:33

1:33

Larson Electronics - American Made and Manufactured Industrial Lighting and UVC Products

11 months agoPortable Power Distribution, 480V-120/240V - 15 KVA

63 -

1:20

1:20

Larson Electronics - American Made and Manufactured Industrial Lighting and UVC Products

3 years agoLED Wall Pack Flood Light for Hazardous Locations - 6,300 Lumens - Class 1 Division 2

96 -

1:05

1:05

Larson Electronics - American Made and Manufactured Industrial Lighting and UVC Products

3 years ago60 Watt Work Area LED Dock Light - 6' Switch Blade Dock Light - 5400 Lumens - 120-277V AC

18 -

2:49

2:49

Larson Electronics - American Made and Manufactured Industrial Lighting and UVC Products

3 years agoPAINT SPRAY BOOTH LED LIGHT - Hazardous Location Lighting Class I, II, III Low Profile 7200 Lumens

71 -

1:09

1:09

Larson Electronics - American Made and Manufactured Industrial Lighting and UVC Products

3 years agoLED MACHINE LIGHT - 1530 Lumens Magnetic Ball Joint Gooseneck - IP65

108 -

1:07

1:07

Larson Electronics - American Made and Manufactured Industrial Lighting and UVC Products

3 years agoSolar Power Generator with Light Tower Mast - 600 Watt

127 -

2:12:46

2:12:46

Price of Reason

20 hours agoAmber Heard BACKS Blake Lively Lawsuit Against Justin Baldoni! Is Disney CEO Bob Iger in TROUBLE?

44.6K13 -

1:01:17

1:01:17

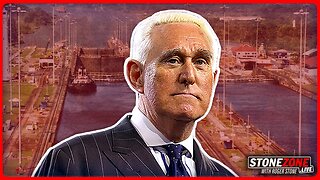

The StoneZONE with Roger Stone

15 hours agoChristmas Edition: Why the Panama Canal is Part of the America First Agenda | The StoneZONE

117K44 -

18:12:15

18:12:15

LFA TV

1 day agoLFA TV CHRISTMAS EVE REPLAY

133K14 -

13:32

13:32

Scammer Payback

16 hours agoChanging the Scammer's Desktop Background to his Location

6.35K3