Premium Only Content

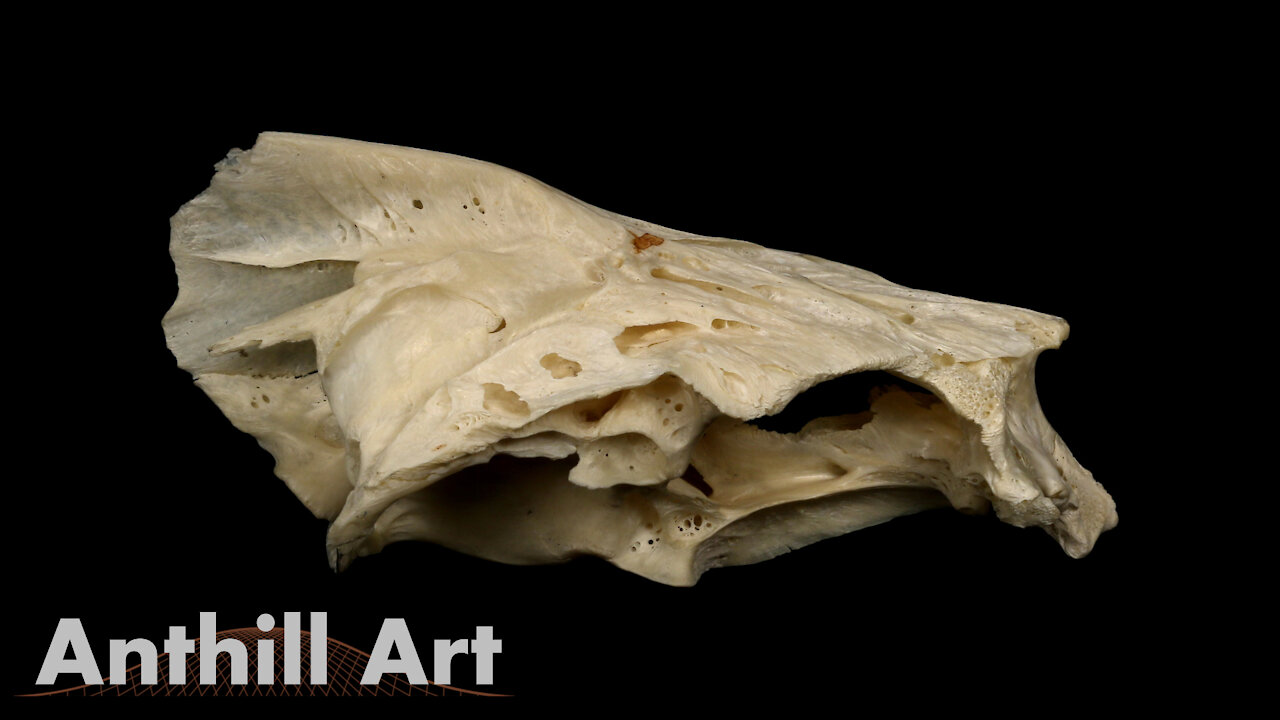

Casting the Inside of a Fish Skull with Aluminum Alloy

In this video, I make a cast of the inside of a fish skull with molten aluminum. I caught this 29 lb black drum a few years ago off the coast of Dauphin Island, Alabama in the Gulf of Mexico. I've had the skull displayed on a cabinet in my shop for a few years and recently thought it might be cool to cast it in molten aluminum.

Hopefully, it's clear in the video what I'm doing and why but if not, here is a detailed explanation:

I can't just pour aluminum into the skull without preparations because it would spill out of the eye sockets and other openings. In order to prevent that from happening, I'm going to encase the skull in plaster before casting. That presents a new problem, because the plaster would fill the skull and leave nothing to cast with aluminum.

To get around these problems, I sealed off all of the exterior openings with tape, except for the spinal cord opening which will be where the aluminum flows in. Then the skull is filled with wax. The solidified wax acts as a barrier to keep the plaster out of the skull.

Next, the tape is removed and the skull is encased in plaster which will keep the aluminum from bursting through the skull while the it hardens. The plaster mold is then placed into an oven to remove the wax, and as much moisture as possible. You can see in the video that there was still a bit of moisture in the plaster which is why it bubbles so much.

After the wax is removed the aluminum is poured in.

I was actually surprised that this worked so well. I wasn't sure if the skull would burn up too quickly and ruin the cast. It worked though. The coolest part is the brain cavity, which has two circular loops jutting out.

-

2:25

2:25

Anthill Art

4 years agoCasting a Mushroom with Molten Aluminum (Cast #091)

80 -

2:45

2:45

Anthill Art

4 years agoCasting a Fire Ant Colony with Molten Aluminum

117 -

2:03

2:03

Anthill Art

4 years ago $0.01 earnedCasting a Carpenter Ant Colony with Molten Aluminum (Cast #042)

112 -

0:32

0:32

Electronic Investigation

3 years agoCNC aluminum with simple G code -early testing

1083 -

0:44

0:44

WFTS

3 years agoSearch for stolen SUV with child inside

97 -

0:17

0:17

DoreenAlegre

4 years agoFISH GRILLED INSIDE COCONUT HUSK

30 -

0:13

0:13

Just the News

4 years agoProtesters fight with police inside Capitol Building

101K57 -

37:24

37:24

MichaelBisping

20 hours agoEDDIE ALVAREZ: Predicts Islam vs Arman, BKFC KnuckleMania, UFC 311 & More! (Interview)

7.15K3 -

22:04

22:04

Scammer Payback

13 hours agoCrazy Scammers Spoof Emergency 911

23.9K8 -

8:28

8:28

Misha Petrov

18 hours agoLiberals OUTRAGED Over Carrie Underwood Performing at Trump’s Inauguration

17.9K25