Premium Only Content

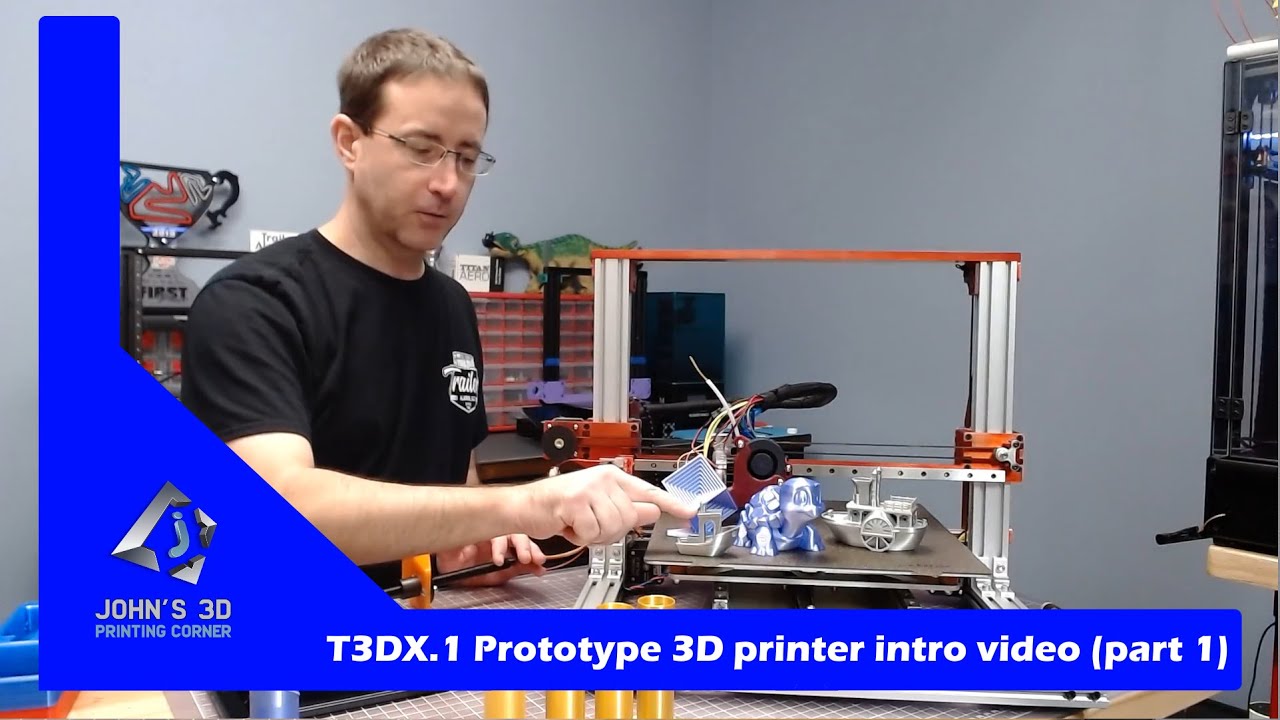

New #3DPrinter design that I am working on - the T3DX.1 Printer with Hemera extruder (Part 1)

This is something I have been working on in various stages for a few years. Originally, I was working the belted Z-axis into a triple Z CoreXY printer. Due to time constraints with work, I switched gears and designed this "i3" style printer.

Edit: Video was taken in May, check Instagram for more pictures.

Disclaimer: Sorry for the noise in the shop, several printers were working in the background along with an AC. I am still talking slowly in the videos, please feel free to speed up the video! ;) Special guest near the end of the video.

Printer Features so far:

310mm x 320mm bed and useable print area

Z height is easy to change, currently building 175mm and 300mm versions

10mm Aluminum top brace for helping support the upper Z blocks

will add LED lights to the brace soon

Misumi extrusion for the frame

Duet Wifi mainboard (Maestro was only used in this video)

Ability to use Railcore 2 extruder carriages, opening up lots of existing extruder mounts

Ability to move the nozzle off the bed for purging and wiping (great for color changes)

LDO 0.9* Steppers

Gates belts, idlers, and shoulder bolts on each axis

LDO Linear Rails on each axis

Bed frame designed to hold a CR10S plate, or the Prusa MK3 plate

Auto Tram bed level along the X-axis

High Z resolution for smooth mesh compensation where needed

Any questions please ask.

Print pictures on my Instagram:

https://www.instagram.com/j_wmueller/

Discord - http://bit.ly/T3DX_Printers

I am currently building several more of these for beta testers to abuse, they will have the BMG-M extruder with Mosquito hotends. Part 2 of the video will feature these updates along with SLS parts on the Z-axis. Herema extruder is featured in this video.

I minimized the use of printed parts and used CNC carbon fiber and aluminum. Aluminum and Titanium parts were cut by www.SendCutSend.com

Please share, I am working on producing this printer in limited qty to start out. My goal was to have an accurate machine with greatly reduced Z artifacts. While it is a large footprint machine it fits well on industrial shelves and workbenches. Other sizes are planned and in development.

Thanks for watching, more videos on the way as some of my core business slows down.

Haircut provided by watching other videos! :) #ComingSoon #3DPrinter #3DPrinting #E3DOnline #Filastruder

-

5:54

5:54

Emencer

3 years ago $0.07 earnedWorking with a mobile crusher

126 -

3:27

3:27

WXYZ

3 years agoWorking out with MaxPro Fitness

127 -

2:45

2:45

KERO

3 years agoNew program working to help educators deal with stress

45 -

0:25

0:25

TSaripin

4 years agoWorking with my buddy

30 -

8:10

8:10

FUZIONREPORT

4 years agoDESIGN with - Sarah St.Amand

66 -

1:00

1:00

Athenia99

3 years agoGround Working with a Leopard Spotted MorApp Pt.1

24 -

0:26

0:26

BDEEP6868

4 years agoFirefighters working with chainsaw

111 -

0:55

0:55

Hoa

4 years agoWalking with the dog (part 1)

15 -

3:28

3:28

Soundlord1

4 years ago $43.38 earnedAlan Howarth's story about working with Steven Spielberg on Poltergeist

40.9K2 -

1:52

1:52

KGUN

3 years agoCOVID relief: Tucson Council working to help with utility bills

12