Premium Only Content

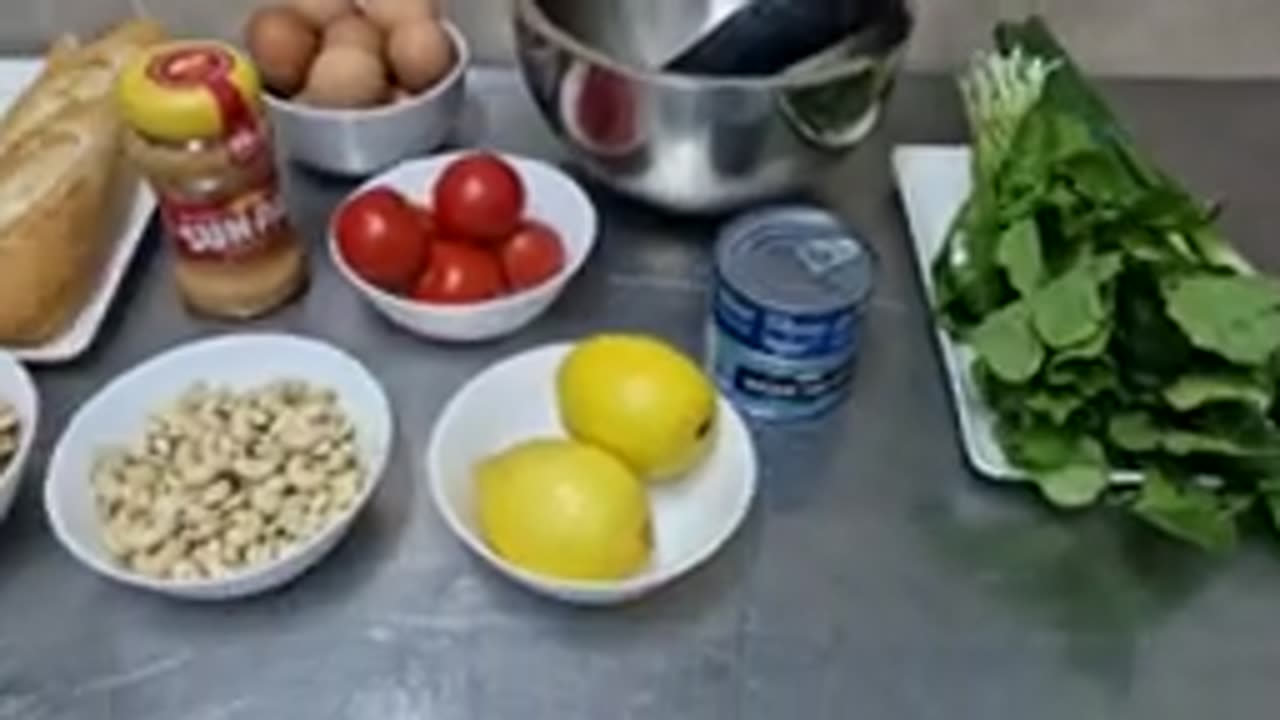

Accredited Food Safety -Keeping Equipment Separate

In accredited food safety courses, keeping equipment separate is a critical topic under **cross-contamination prevention**. Here's a summary of what this entails:

### Why Keep Equipment Separate?

Keeping equipment separate reduces the risk of cross-contamination, which occurs when harmful bacteria or allergens are transferred from one surface or food item to another. This is especially important for:

- **Raw and cooked foods** (e.g., raw meat and ready-to-eat food)

- **Allergen control** (e.g., peanuts vs. non-allergen products)

- **Different food types** (e.g., seafood, poultry, vegetables)

---

### Best Practices for Keeping Equipment Separate:

1. **Use Color-Coded Equipment**:

- Assign specific colors to equipment for different food types.

Example:

- **Red**: Raw meat

- **Blue**: Raw fish

- **Green**: Vegetables

- **Yellow**: Cooked or ready-to-eat foods

2. **Dedicated Storage**:

- Store cutting boards, knives, and utensils used for different food groups separately.

- Use sealed containers for allergen-containing ingredients.

3. **Sanitization and Cleaning**:

- Clean and disinfect equipment thoroughly between uses.

- Use separate cleaning materials (e.g., sponges and brushes) for high-risk equipment.

4. **Labeling**:

- Clearly label containers, utensils, and areas for specific purposes.

5. **Training Staff**:

- Train all employees in food safety practices, emphasizing the importance of equipment separation.

---

### Food Safety Certifications Covering This:

- **HACCP (Hazard Analysis and Critical Control Points)**

- **ServSafe** (USA)

- **NEA Food Safety Course** (Singapore)

- **Level 2/3 Food Hygiene Certificates** (UK and EU)

Would you like more detailed information about a specific certification or additional practices?

-

3:18

3:18

HSESafetyInformation

9 days agoDahi Champ (Mutton Chops) Recipe By Food Fusion

29 -

DVR

DVR

Bannons War Room

9 days agoWarRoom Live

2.32M410 -

2:17:39

2:17:39

Matt Kohrs

12 hours agoBREAKING MARKET NEWS: Bounce or Bust?! || The MK Show

33.1K1 -

47:26

47:26

BonginoReport

4 hours agoEpstein Files Drop Today-But How Much Will They Reveal? (Ep.149) - 02/27/2025

94.8K134 -

2:59:16

2:59:16

Wendy Bell Radio

7 hours agoThe Left Is Wrong About Everything

71.2K45 -

29:05

29:05

CatfishedOnline

20 hours ago $3.48 earnedThe Real Jennifer Aniston or Another Romance Scam?

34.8K10 -

34:44

34:44

LFA TV

5 days agoMIRACLES DO HAPPEN!

65.5K3 -

16:43

16:43

T-SPLY

5 hours agoCNN Panel Member Forgets Donald Trump Runs The Military

40.1K24 -

31:13

31:13

World Nomac

1 day agoAMERICAN visits IRAN for 10 days (this is what I found) 🇮🇷

36.6K4 -

1:03:55

1:03:55

The Tom Renz Show

12 hours agoBongino In At FBI & Is Factory Meat Made of Cancer?

40.6K10