Premium Only Content

Restaurant SFBB Training- Cross contaminaton by Dirty Equipment

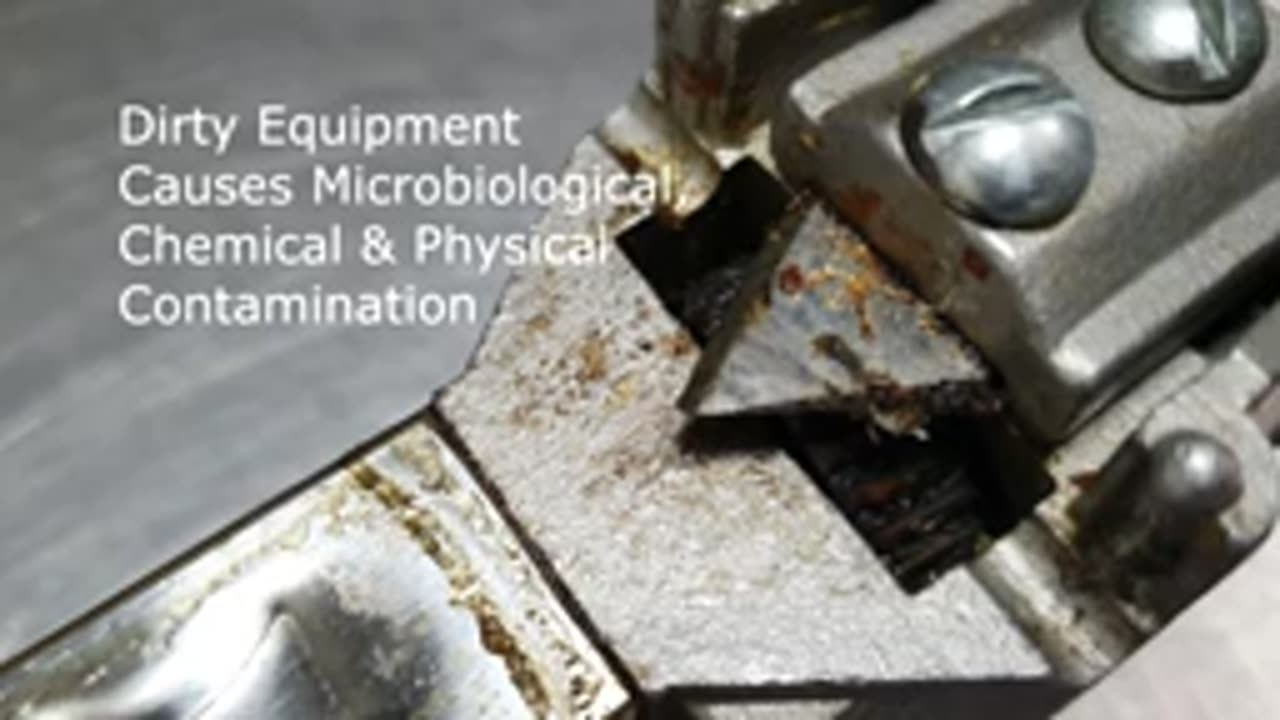

### **Cross-Contamination by Dirty Equipment in Restaurants: SFBB Training**

In the **Safer Food Better Business (SFBB)** framework, dirty or improperly cleaned equipment is a major cause of cross-contamination in restaurants. Harmful bacteria like **Salmonella**, **E. coli**, and **Listeria** can transfer from raw food residue or allergens to ready-to-eat foods, utensils, and surfaces. Preventing this is critical for food safety and achieving compliance with UK food hygiene regulations.

---

### **How Dirty Equipment Causes Cross-Contamination**

1. **Direct Transfer**: Residue from raw food on unclean knives, chopping boards, or utensils contaminates ready-to-eat food.

2. **Build-Up of Bacteria**: Equipment not cleaned properly allows bacteria to multiply, especially if left at room temperature.

3. **Allergen Risks**: Traces of allergens left on equipment can pose serious health risks to customers with allergies.

4. **Pest Contamination**: Dirty equipment attracts pests, increasing the risk of contamination.

---

### **Examples of Risky Practices**

- Using the same knife for raw chicken and cooked food without cleaning.

- Chopping vegetables on a board previously used for raw meat.

- Failing to clean and sanitize mixers, slicers, or other machinery between uses.

- Neglecting to clean equipment thoroughly after allergen exposure (e.g., nuts, gluten-containing products).

---

### **SFBB Guidelines for Preventing Cross-Contamination by Dirty Equipment**

#### **1. Use Colour-Coded Equipment**

- Assign specific colours to different food types (e.g., red for raw meat, green for vegetables, yellow for cooked food).

- Ensure staff are trained to use the correct equipment for each task.

#### **2. Clean and Sanitize Equipment Regularly**

- **After Each Use**: Clean knives, boards, utensils, and machines immediately after use with hot, soapy water and a food-safe sanitizer.

- **Deep Cleaning**: Schedule regular deep cleans of all kitchen equipment, especially hard-to-reach areas in slicers, blenders, and mixers.

- **Disassemble When Necessary**: Take apart complex equipment to ensure all parts are cleaned.

#### **3. Replace Worn Equipment**

- Discard cutting boards, utensils, or other equipment with cracks, scratches, or excessive wear where bacteria can hide.

- Replace sponges and cleaning cloths frequently to avoid spreading bacteria.

#### **4. Implement Cleaning Schedules**

- Use the SFBB **cleaning checklist** to ensure all equipment is cleaned and sanitized regularly.

- Display cleaning schedules where staff can see them, assigning responsibility for each task.

#### **5. Train Staff**

- Train all team members to understand the risks of dirty equipment and proper cleaning procedures.

- Emphasize the importance of cleaning and sanitizing after handling raw food or allergens.

---

### **Proper Cleaning Procedure for Equipment**

1. **Pre-Clean**: Remove leftover food debris by rinsing or wiping the equipment.

2. **Wash**: Use hot water (at least 60°C) and a detergent to wash all surfaces.

3. **Rinse**: Rinse with clean, hot water to remove detergent and loosened debris.

4. **Sanitize**: Apply a food-safe sanitizer to kill bacteria. Follow the manufacturer's instructions for contact time.

5. **Dry**: Allow equipment to air-dry completely or use disposable paper towels. Avoid using reusable cloths that can reintroduce bacteria.

---

### **Key Areas to Monitor for Dirty Equipment Risks**

- **Chopping Boards**: Ensure they’re cleaned between tasks and replaced if deeply scratched.

- **Knives and Utensils**: Wash immediately after use, especially between raw and ready-to-eat foods.

- **Mixers and Blenders**: Disassemble and clean thoroughly after each use.

- **Storage Racks and Drawers**: Check for dirt and residue build-up.

- **Handheld Equipment**: Thermometers, tongs, and other small tools must be cleaned regularly.

---

### **SFBB Record Keeping**

- Use the **Cleaning Schedule Log** in the SFBB pack to document:

- Daily cleaning tasks.

- Who performed the cleaning.

- Verification that tasks were completed.

- Keep records up-to-date for inspections and audits.

---

### **Benefits of Proper Equipment Hygiene**

1. Prevents foodborne illnesses caused by bacterial contamination.

2. Reduces the risk of allergen cross-contact.

3. Improves compliance with **Food Hygiene Ratings** (aiming for 5 stars).

4. Ensures a safe and clean environment for food preparation.

Would you like a **custom cleaning checklist** or assistance tailoring the SFBB training materials to your restaurant's operations?

-

58:50

58:50

Laura Loomer

6 hours agoThe Great Replacement (Full-Length Documentary)

38.4K28 -

Razeo

6 hours agoEp 31: Finishing March Ridge & onto Muldraugh tonight

34.1K1 -

1:00:37

1:00:37

Adam Does Movies

5 hours ago $5.12 earnedBatman II Update + Flash Director Fails + Movie Bombs! - LIVE!

49.4K5 -

2:26:24

2:26:24

We Like Shooting

19 hours ago $1.18 earnedWe Like Shooting 593 (Gun Podcast)

33.3K -

57:03

57:03

Flyover Conservatives

1 day agoJack Hibbs Blasts California Leaders: Must-Watch!; Can Trump Fix the Mess? How Long will it Take? - Dr. Kirk Elliott | FOC Show

56.4K7 -

2:00:50

2:00:50

DillyDillerson

6 hours agoTalking to the moon!! Just some live views of the FULL MOON!!

35.8K11 -

1:29:29

1:29:29

Glenn Greenwald

10 hours agoWith Biden Out, U.S. Finally Admits Harms of His Israel / Gaza Policy; Biden Pays Homage To George W. Bush; Insane Women’s Tennis Scandal: An “Abusive” Coach | SYSTEM UPDATE #388

71.3K95 -

3:12:23

3:12:23

Danny Polishchuk

12 hours agoWho's To Blame For LA Fires, Jewish Tunnels Update + Forbidden Anthropology

32K5 -

1:08:10

1:08:10

Donald Trump Jr.

12 hours agoOne Week Until Inauguration, Live with Rep Anna Paulina Luna & Sen Tommy Tuberville

133K201 -

1:00:13

1:00:13

The StoneZONE with Roger Stone

8 hours agoLAWFARE! Are Trump's Legal Assaults Winding Down? w/ Impeachment Lawyer David Schoen | The StoneZONE

40.4K