Premium Only Content

Powered Industrial Truck Labels

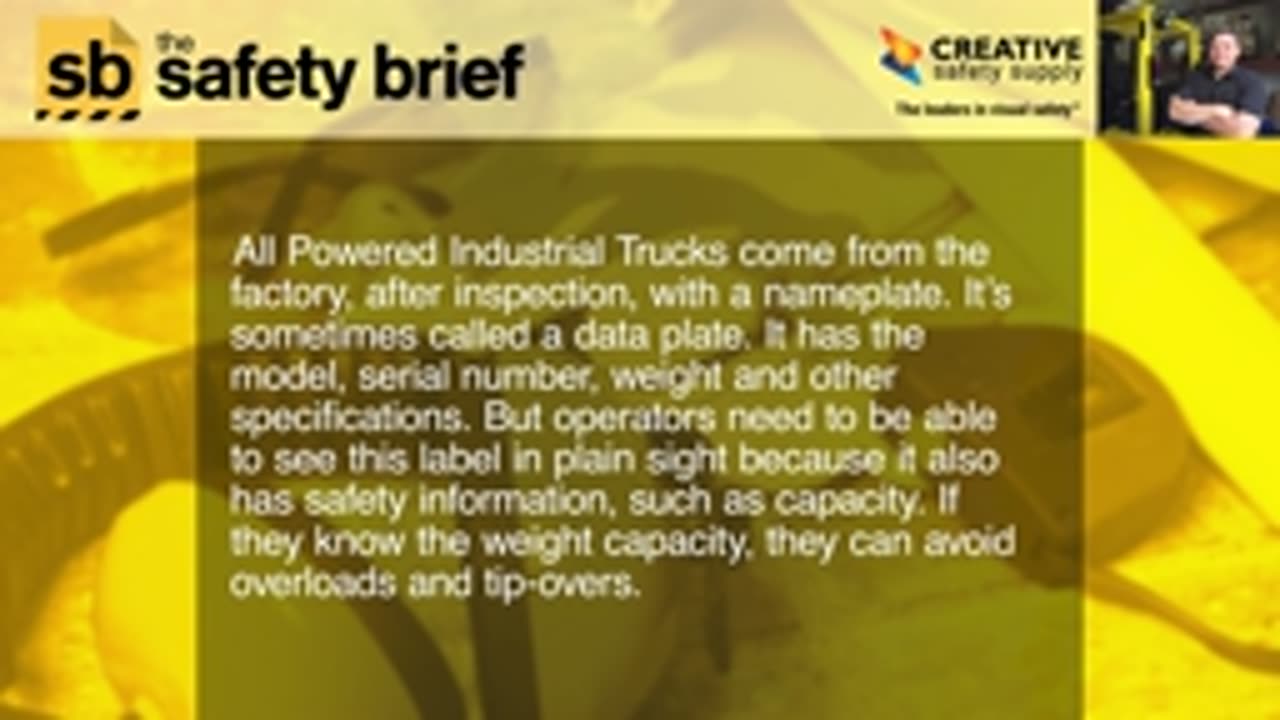

### **Powered Industrial Truck Labels: The Safety Brief**

Powered industrial trucks, such as forklifts, require proper labeling to ensure safety and compliance with regulations. This brief outlines the key types of labels, their importance, and how to maintain them.

---

### **1. Importance of Labels**

- **Safety**: Labels provide critical warnings to prevent accidents and injuries.

- **Compliance**: OSHA and ANSI require clear, legible labels for powered industrial trucks.

- **Operator Awareness**: Labels convey important operational and maintenance information.

---

### **2. Types of Labels on Powered Industrial Trucks**

#### **A. Manufacturer’s Label**

- **Truck Specifications**: Includes model number, weight, and load capacity.

- **Fuel Type**: Identifies if the truck uses gas, diesel, propane, or electricity.

- **Operator Restrictions**: Notes if only trained personnel can operate the truck.

#### **B. Load Capacity Chart**

- **Maximum Load Weight**: Specifies the truck's load capacity at different mast angles and heights.

- **Center of Gravity**: Indicates the load center distance for stability.

- **Overloading Warning**: Alerts operators about the risks of exceeding capacity.

#### **C. Warning Labels**

- **General Safety Warnings**: Alerts operators to avoid dangerous behaviors (e.g., riding on forks).

- **Blind Spot Warnings**: Highlights blind areas where visibility is limited.

- **Tip-Over Prevention**: Includes graphics and instructions to avoid overturns.

#### **D. Operational Controls**

- **Control Identification**: Labels identify pedals, levers, and switches for operating the truck.

- **Emergency Procedures**: Provides instructions for emergency shut-off or brake use.

#### **E. Maintenance Labels**

- **Inspection Reminders**: Indicates when the truck was last serviced or inspected.

- **Battery Safety**: Includes precautions for handling and charging batteries.

- **Fluid Level Warnings**: Notes requirements for checking oil, hydraulic fluid, or coolant levels.

---

### **3. Maintaining Labels**

- **Keep Labels Clean**: Wipe labels regularly to ensure they remain legible.

- **Replace Damaged Labels**: Replace worn, faded, or missing labels immediately.

- **Use Manufacturer-Approved Labels**: Ensure replacements match original specifications.

---

### **4. Regulatory Compliance**

- **OSHA Standards**: Adhere to OSHA regulations for labeling powered industrial trucks.

- **ANSI Guidelines**: Follow ANSI/ITSDF B56.1 for labeling requirements.

- **Local Requirements**: Check for additional state or regional labeling mandates.

---

### **5. Employee Training on Labels**

- **Label Familiarity**: Train operators to understand and use all labels on the truck.

- **Inspection Checks**: Include label verification as part of daily pre-shift inspections.

- **Emergency Awareness**: Ensure employees know the locations and meanings of warning and safety labels.

---

### **Takeaway Message**

Proper labeling on powered industrial trucks is essential for safe operation and regulatory compliance. Regular inspections, maintenance, and employee training will help keep labels effective and legible.

Would you like a printable checklist or infographic for this topic?

-

10:05

10:05

DIY Wife

3 years agoHow We Flip Old Furniture For Profit!

36.9K56 -

2:14:54

2:14:54

TheSaltyCracker

5 hours agoTrump Goes Gangster ReeEEeE Stream 01-26-25

100K229 -

4:42:13

4:42:13

Due Dissidence

14 hours agoTrump Calls To "CLEAN OUT" Gaza, Swiss ARREST Pro-Palestine Journalist, MAGA's Hollywood Makeover?

50.2K72 -

2:02:20

2:02:20

Nerdrotic

6 hours ago $15.86 earnedDECLASSIFIED: JFK, MLK UFO Immaculate Constellation Doc | Forbidden Frontier #089

67.6K15 -

3:00:14

3:00:14

vivafrei

14 hours agoEp. 248: "Bitcoin Jesus" Begs Trump! Rekieta Gets Plea Deal! Pardons, Deportations, Bird Flu & MORE!

161K176 -

3:44:06

3:44:06

Rising Rhino

13 hours ago $12.55 earnedWashington Commanders Vs Philadelphia Eagles: NFL NFC Championship LIVE Watch Party

66.2K4 -

13:00

13:00

Exploring With Nug

7 hours ago $5.55 earnedHe Went To Get A Haircut And Vanished WIthout a Trace!

59.3K2 -

18:53

18:53

DeVory Darkins

2 days ago $30.25 earnedTrump JUST ENDED Mayor Karen Bass During HEATED Meeting

85.5K218 -

21:06

21:06

Russell Brand

11 hours agoIT'S COMING

148K486 -

21:26

21:26

Stephen Gardner

1 day ago🔥What JUST leaked out of Congress must be STOPPED NOW!

140K285