Premium Only Content

Stacking and Storing for Warehouse Safety

### **Stacking and Storing for Warehouse Safety**

#### **The Safety Brief**

Improper stacking and storing in warehouses can lead to accidents, injuries, and damaged goods. This safety brief provides essential guidelines to ensure safe and efficient stacking and storage practices.

---

### **1. Understand Weight Limits and Capacity**

- **Check Load Ratings**: Ensure shelves, racks, and pallets can handle the weight of the items being stored.

- **Follow Forklift Capacity**: Never overload forklifts when stacking items at higher levels.

---

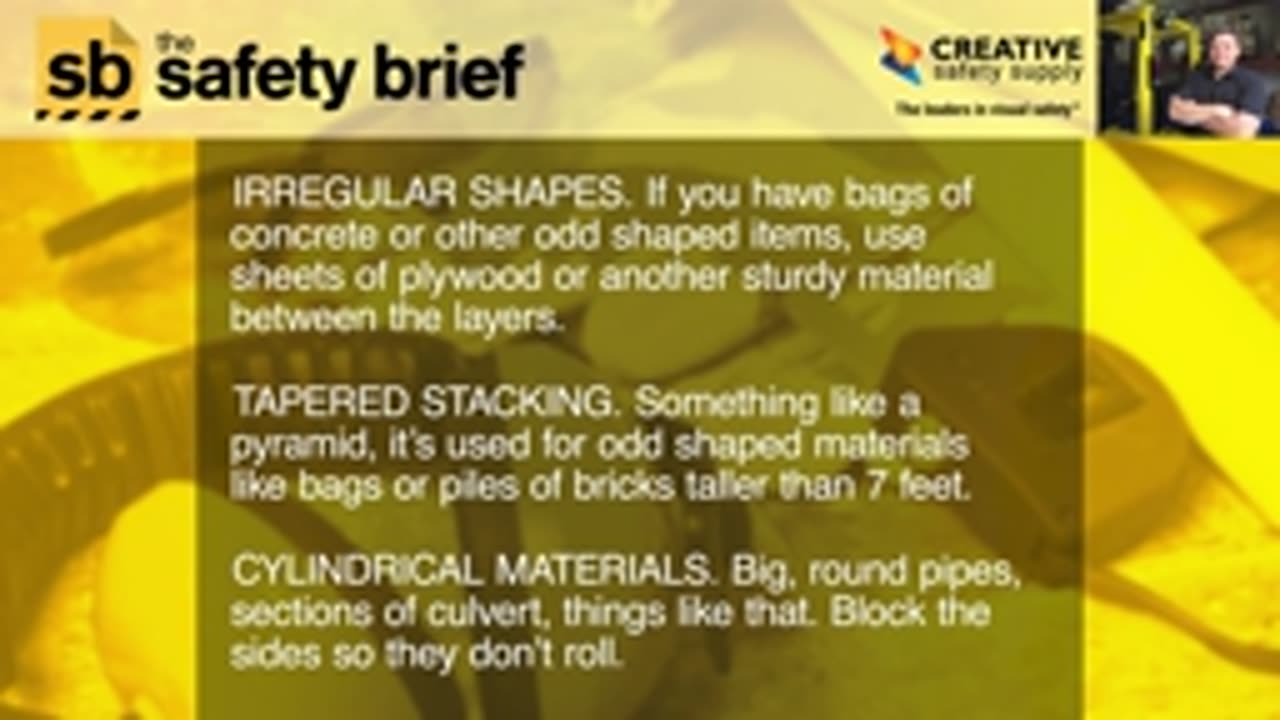

### **2. Proper Stacking Practices**

- **Stack Evenly**: Distribute weight evenly to prevent items from tilting or falling.

- **Heavier Items on Bottom**: Place heavier items at the base to create a stable foundation.

- **Do Not Overstack**: Avoid stacking items too high, especially beyond the height limits of racks or pallets.

---

### **3. Use the Right Equipment**

- **Pallet Jacks and Forklifts**: Use forklifts or pallet jacks to safely handle heavy loads.

- **Securing Tools**: Use shrink wrap, straps, or netting to secure unstable loads.

- **Ladders and Platforms**: Use proper ladders or elevated work platforms to access high stacks safely.

---

### **4. Maintain Clear Aisles**

- **Follow Storage Layout**: Ensure items are stored within designated areas, not in aisles.

- **Allow Clearance**: Keep adequate space between stacks for easy access and to prevent tipping.

- **Emergency Exits**: Never block emergency exits or fire extinguishers with stored items.

---

### **5. Inspect and Maintain Storage Areas**

- **Inspect Shelving and Racks**: Regularly check for damage, rust, or wear that could compromise structural integrity.

- **Clean Spills Promptly**: Address spills immediately to prevent slips or material damage.

- **Avoid Overcrowding**: Store items only within the storage area’s capacity limits.

---

### **6. Special Considerations for Hazardous Materials**

- **Follow Regulations**: Store chemicals and hazardous materials in compliance with OSHA or local safety regulations.

- **Use Proper Containers**: Ensure hazardous materials are in approved containers with proper labeling.

- **Isolate Dangerous Goods**: Store incompatible materials separately to prevent reactions.

---

### **7. Employee Training and Awareness**

- **Provide Training**: Train employees on proper stacking, storing, and material handling techniques.

- **Monitor Practices**: Supervisors should regularly observe and correct unsafe stacking behaviors.

- **Encourage Reporting**: Promote reporting of unsafe storage conditions to prevent incidents.

---

### **Takeaway Message**

Safe stacking and storing are critical to maintaining a hazard-free warehouse. Follow these guidelines to protect employees, prevent accidents, and keep operations running smoothly.

Would you like a more detailed checklist or a visual guide for this topic?

-

1:52:42

1:52:42

Kim Iversen

4 hours ago💰 CHA-CHING! 💰 Trump Unveils Big Money Plans For Gaza AND America

35.2K80 -

1:05:28

1:05:28

Flyover Conservatives

17 hours agoUkraine’s Dirty Secret: The Christian Persecution No One Wants to Talk About - Alex Newman | FOC Show

23.5K5 -

2:00:20

2:00:20

Glenn Greenwald

9 hours agoThe View from Moscow: Key Russian Analyst Aleksandr Dugin on Trump, Ukraine, Russia, and Globalism | SYSTEM UPDATE #414

70K24 -

1:10:55

1:10:55

Donald Trump Jr.

6 hours agoBREAKING NEWS: My Father Revokes Biden-Maduro Oil License, LIVE with Maria Corina Machado | Triggered Ep.220

162K172 -

1:25:29

1:25:29

Sarah Westall

5 hours agoX-Files True History, Project Blue Beam, Cabal Faction War w/ Former FBI Agent John DeSouza

57.4K5 -

7:03:49

7:03:49

Dr Disrespect

12 hours ago🔴LIVE - DR DISRESPECT - NEW PC VS. DELTA FORCE - MAX SETTINGS

146K26 -

49:04

49:04

Lights, Camera, Barstool

1 day agoIs The Monkey The Worst Movie Of The Year?? + Amazon Gets Bond

57.4K4 -

24:19

24:19

Adam Carolla

1 day agoDiddy’s Legal Drama Escalates, Smuggler Caught Hiding WHAT? + Philly Eagles & The White House #news

74.3K13 -

10:12

10:12

Mike Rowe

2 days agoClint Hill: What A Man. What A Life. | The Way I Heard It with Mike Rowe

96.2K10 -

1:31:52

1:31:52

Redacted News

8 hours agoBOMBSHELL! This is war! FBI whistleblowers reveal Epstein files being destroyed? | Redacted News

167K361