Premium Only Content

Crane Safety _ Types of Crane _ Lifting _ Crane Lifting Hazards _ Precautions _ HSE STUDY GUIDE

### **Crane Safety: Types of Cranes, Lifting, Hazards, and Precautions - HSE Study Guide**

Crane safety is critical in ensuring the protection of workers, equipment, and the environment during lifting operations. Understanding the different types of cranes, lifting procedures, common hazards, and safety precautions is essential for safe and efficient crane operations. This HSE (Health, Safety, and Environment) Study Guide outlines the core aspects of crane safety.

---

## **1. Types of Cranes**

Crane types vary based on their design, mobility, and application. Below are some of the most common types of cranes used in construction, industrial, and other lifting operations.

### **1.1. Mobile Cranes**

- **Description:** Cranes mounted on wheels or tracks that can be moved from one location to another.

- **Applications:** Used for a wide range of lifting tasks in construction sites, industrial areas, and loading docks.

- **Key Features:** Flexible, easy to transport, and can lift heavy loads. Equipped with outriggers for stability.

### **1.2. Tower Cranes**

- **Description:** Fixed cranes commonly used in the construction of tall buildings.

- **Applications:** Primarily used in high-rise construction projects.

- **Key Features:** High lifting capacities, vertical reach, and the ability to rotate 360 degrees.

### **1.3. Overhead Cranes (Bridge Cranes)**

- **Description:** Cranes that run on rails along the ceiling of a building or structure.

- **Applications:** Typically used in factories, warehouses, or large industrial environments.

- **Key Features:** Can lift loads vertically and move horizontally across large areas.

### **1.4. Gantry Cranes**

- **Description:** Similar to overhead cranes but with the ability to move across rails on the ground.

- **Applications:** Used in ports, rail yards, and warehouses for lifting containers and heavy loads.

- **Key Features:** Can operate outside and indoors, offering more mobility and flexibility in lifting.

### **1.5. Crawler Cranes**

- **Description:** Cranes mounted on crawler tracks, ideal for rough terrain.

- **Applications:** Commonly used in construction sites, infrastructure projects, and mining operations.

- **Key Features:** High lifting capacity and mobility on soft or uneven ground.

### **1.6. Floating Cranes**

- **Description:** Cranes mounted on barges or ships for marine operations.

- **Applications:** Used in offshore construction, dredging, and shipping operations.

- **Key Features:** Ability to lift heavy loads on water bodies.

---

## **2. Lifting Operations**

### **2.1. Proper Lifting Procedures**

- **Pre-Lift Planning:** Prior to any lifting operation, it is essential to plan the lift, including determining the load weight, center of gravity, lifting points, rigging methods, and safety protocols.

- **Load Chart Consultation:** Always refer to the crane's load chart to ensure the crane can safely lift the intended load.

- **Slinging and Rigging:** Ensure the correct rigging is used for the load, and inspect slings, shackles, hooks, and other rigging equipment for damage before use.

- **Communication:** Establish clear communication between the crane operator and ground crew. Use hand signals, radios, or other reliable methods.

### **2.2. Safety During Lifting**

- **Stabilization:** Always ensure the crane is stable before beginning any lifting operation. This involves ensuring that outriggers are properly deployed, and the crane is on a solid and level surface.

- **Lifting and Lowering:** Avoid abrupt movements when lifting and lowering loads. Maintain smooth, controlled motions to prevent sudden jerks or shifts in the load.

- **Load Control:** If necessary, use taglines to control the load and minimize swinging.

---

## **3. Crane Lifting Hazards**

### **3.1. Overloading**

- **Description:** Lifting a load that exceeds the crane's rated capacity can lead to tipping, structural damage, or crane collapse.

- **Precaution:** Always check the crane's load chart and ensure the load does not exceed the crane's rated load capacity for the specific lifting configuration.

### **3.2. Crane Tipping**

- **Description:** Crane tipping occurs when the crane loses stability, usually due to overloading, improper positioning, or a soft or uneven ground surface.

- **Precaution:** Ensure proper crane setup, use outriggers, and avoid sudden movements or overloading.

### **3.3. Falling Loads**

- **Description:** Loads can fall if they are not properly secured or if rigging equipment fails.

- **Precaution:** Ensure all loads are secured before lifting, and inspect rigging equipment to ensure it's in good condition. Never lift a load over people.

### **3.4. Crane Collapse**

- **Description:** A crane can collapse if it's not properly maintained, or if the lifting operation is conducted improperly.

- **Precaution:** Perform regular inspections, follow manufacturer guidelines for crane operation, and ensure all safety devices are functional.

### **3.5. Swinging Loads**

- **Description:** Loads that swing uncontrollably during lifting can create hazards for workers and other equipment.

- **Precaution:** Use taglines to control load movement, ensure the load is balanced, and avoid sudden jerks.

### **3.6. Contact with Electrical Lines**

- **Description:** Cranes that come into contact with overhead electrical lines pose a significant risk of electrocution.

- **Precaution:** Always maintain a safe distance from electrical lines and ensure that workers are aware of the risks of working near power lines.

---

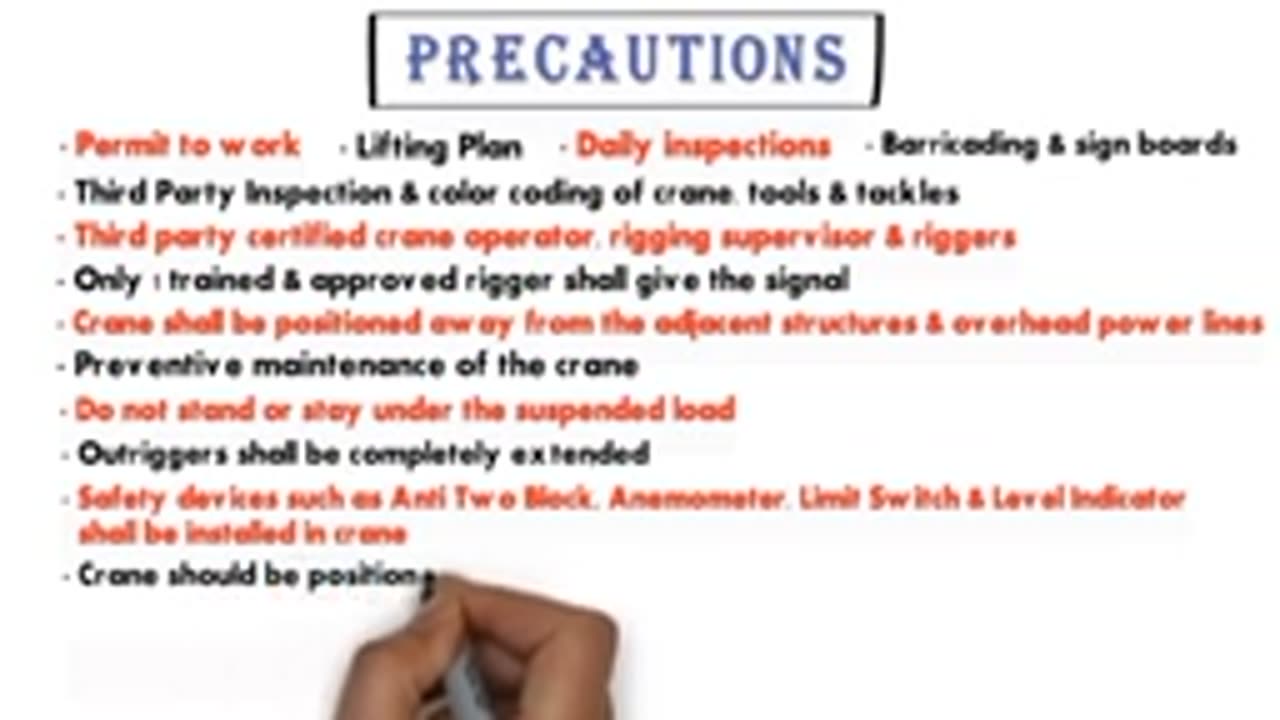

## **4. Safety Precautions for Crane Operations**

### **4.1. Operator Training and Certification**

- **Tip:** Ensure crane operators are properly trained and certified according to local regulations (e.g., OSHA, ISO).

- **Reason:** A well-trained operator is better equipped to identify hazards and perform safe lifting operations.

### **4.2. Regular Crane Inspections**

- **Tip:** Conduct pre-operational inspections before each crane use and implement a routine maintenance schedule.

- **Reason:** Identifying and fixing mechanical issues before use helps prevent accidents.

### **4.3. Maintain Safe Working Radius**

- **Tip:** Always establish a safety radius around the crane to keep workers and equipment out of harm’s way.

- **Reason:** This reduces the risk of falling objects, load swinging, and crane instability.

### **4.4. Properly Set Up Crane on Stable Ground**

- **Tip:** Ensure the crane is positioned on level ground and that all outriggers are fully extended and placed on stable surfaces.

- **Reason:** This helps prevent tipping and ensures the crane’s stability during operations.

### **4.5. Use of Personal Protective Equipment (PPE)**

- **Tip:** Ensure that all personnel involved in crane operations wear appropriate PPE, including hard hats, steel-toe boots, gloves, and high-visibility vests.

- **Reason:** PPE protects workers from potential hazards such as falling objects or sharp rigging components.

### **4.6. Weather Conditions Monitoring**

- **Tip:** Never operate a crane in severe weather conditions such as high winds, lightning, or heavy rain.

- **Reason:** Weather conditions can drastically affect crane performance and safety.

### **4.7. Avoiding Blind Lifts**

- **Tip:** Ensure that the crane operator has clear visibility of the load and the surrounding area. Use spotters or signal persons if necessary.

- **Reason:** Blind lifts increase the risk of accidents due to lack of awareness of the surrounding environment.

### **4.8. Properly Rigging the Load**

- **Tip:** Use the correct rigging equipment, ensuring it is rated for the load being lifted.

- **Reason:** Incorrect rigging can lead to load slippage or equipment failure.

---

## **5. Conclusion**

By following the proper crane safety protocols, understanding lifting operations, and identifying potential hazards, crane accidents can be minimized. Regular inspections, operator training, clear communication, and adherence to safety precautions are essential for a safe lifting environment.

If you need further clarification on any specific crane safety procedures or would like more examples, feel free to ask!

-

12:42

12:42

Cooking with Gruel

20 hours agoBrown Butter Trifle with Salted Caramel and Cinnamon Apple

14.4K3 -

2:46

2:46

BIG NEM

9 hours agoDiscovering RAKIJA: The Holy Liquer of the Balkans

11.8K2 -

1:11:38

1:11:38

Film Threat

14 hours agoCHRISTMAS DAY CHILL STREAM WITH CHRIS GORE | Hollywood on the Rocks

134K30 -

14:22:40

14:22:40

The Quartering

1 day agoYule Log Christmas MAGA Edition With Memes! Come Hang Out!

224K29 -

38:41

38:41

MYLUNCHBREAK CHANNEL PAGE

1 day agoTimeline Begins in 1800? - Pt 1 & 2

104K56 -

1:23:41

1:23:41

Game On!

1 day ago $13.56 earnedNetflix NFL Christmas Games Preview and Predictions!

91.2K12 -

2:05:07

2:05:07

Darkhorse Podcast

1 day agoWhy Trump Wants Greenland: The 257th Evolutionary Lens with Bret Weinstein and Heather Heying

319K876 -

8:50:58

8:50:58

Right Side Broadcasting Network

1 day ago🎅 LIVE: Tracking Santa on Christmas Eve 2024 NORAD Santa Tracker 🎅

417K65 -

2:48

2:48

Steven Crowder

1 day agoCROWDER CLASSICS: What’s This? | Nightmare Before Kwanzaa (Nightmare Before Christmas Parody)

366K13 -

33:49

33:49

Quite Frankly

1 day agoThe Christmas Eve Midnight Telethon

150K30