Premium Only Content

Lifting Shackle Load Calculation _ D-Shackle_Bow Shackle Load Calculation _ HSE STUDY GUIDE_2

### **Lifting Shackle Load Calculation - D-Shackle and Bow Shackle**

Lifting shackles are critical components in lifting operations, used to connect slings, chains, or other lifting equipment to the load. The correct selection and load calculation of shackles are crucial for ensuring safe lifting operations. Below is a detailed study guide on how to calculate the load capacity of **D-shackles** and **bow shackles**.

---

## **1. Types of Shackles**

### **1.1. D-Shackles**

- **Shape:** "D" shaped, with a pin running through the narrower section.

- **Strength:** D-shackles are typically stronger than bow shackles, as the load is applied directly along the line of the shackle's body.

- **Use:** Commonly used in situations where the load is aligned with the pin direction, such as in simple, straight-line lifting.

### **1.2. Bow Shackles**

- **Shape:** "Bow" shaped, with a wider, more rounded body.

- **Strength:** Bow shackles can handle loads from different directions because of their wider shape, which distributes the load more evenly across the body.

- **Use:** Typically used for multi-directional loads or when more flexibility in load direction is needed.

---

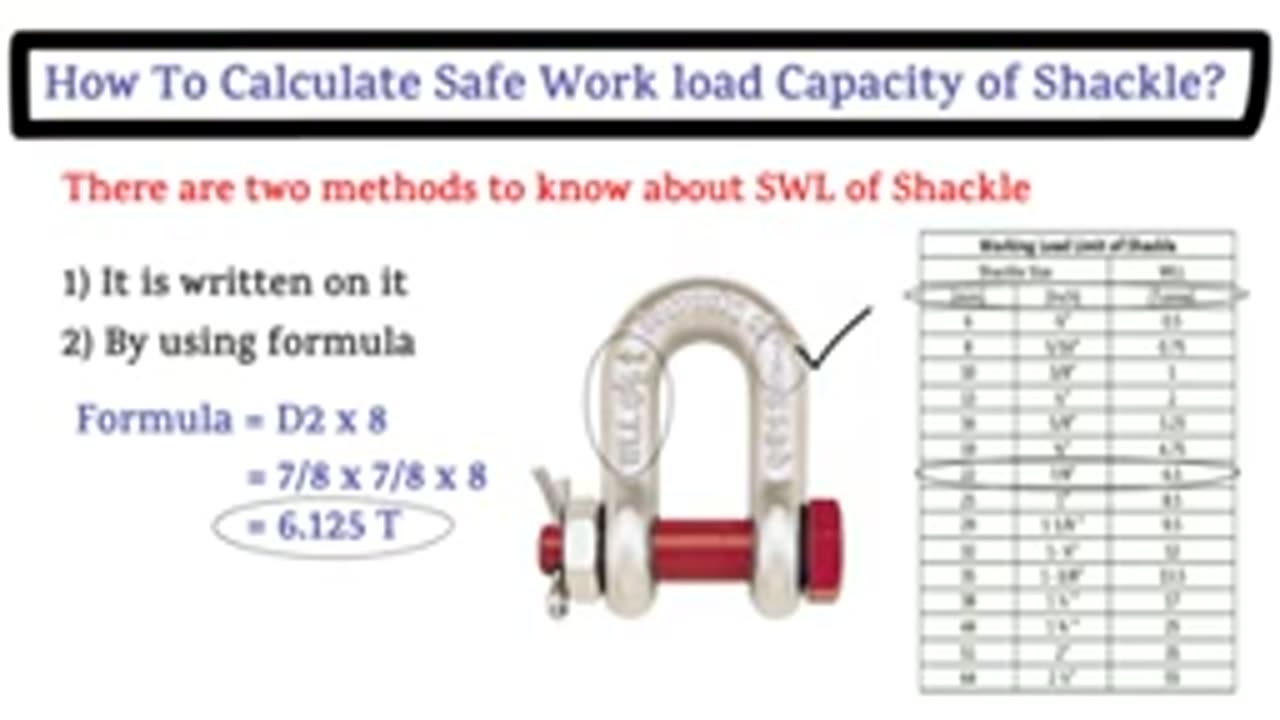

## **2. Shackle Load Calculations**

To calculate the maximum load that a shackle can safely handle, we need to consider several factors, including the shackle's **Working Load Limit (WLL)**, material strength, and safety factor. The WLL is typically marked on the shackle or specified by the manufacturer. The following steps outline how to perform lifting shackle load calculations:

### **2.1. Understanding the Load Capacity of Shackles**

#### **Load Capacity Formula:**

- **WLL = (Shackle Breaking Strength) / Safety Factor**

Where:

- **WLL** is the working load limit (safe load the shackle can handle).

- **Shackle Breaking Strength (BS)** is the maximum load the shackle can endure before failure (typically provided by the manufacturer).

- **Safety Factor (SF)** is a multiplier used to account for uncertainty and to ensure a margin of safety. It usually ranges between **4:1** to **6:1**, depending on the type of load and local regulations.

For example, if the breaking strength of the shackle is **50 tons**, and the safety factor is **5:1**:

- **WLL = 50 tons / 5**

- **WLL = 10 tons** (the safe working load)

---

### **2.2. Calculating the Load on a Single Shackle (Straight Line)**

If the load is applied in a straight line, the load on the shackle is simply the weight of the load being lifted. In this case, you can directly use the WLL.

For example:

- If a D-shackle has a **WLL of 10 tons**, it can safely lift a load of **10 tons** in a straight line.

### **2.3. Calculating Load When Using Multiple Shackles**

When using multiple shackles in a lifting system, the load is typically shared between the shackles. The calculation varies based on the number of shackles used and the load configuration.

- **Example:** Two shackles in a **slings** configuration (using a two-leg sling):

- Assume each shackle has a **WLL of 10 tons**.

- If the load is evenly distributed, each shackle can bear **5 tons** (half of the total load).

- If one shackle is bearing the entire load due to improper sling configuration, it will carry the full weight.

---

### **2.4. Sling Angle and Load Distribution**

If the load is not applied in a straight line but at an angle (as is often the case in lifting operations), the load on each shackle increases based on the angle of the sling. The load calculation needs to account for the increased tension caused by the angle.

**Formula for Load Distribution with Sling Angles:**

- **Tension = Load / (Number of Shackles × cos(θ))**

Where:

- **θ** is the angle of the sling relative to the horizontal (the lower the angle, the higher the load tension).

---

## **3. Safety Considerations**

When selecting shackles for lifting operations, consider the following to ensure safe use:

### **3.1. Working Load Limit (WLL)**

Always ensure the WLL of the shackle exceeds the actual load that will be applied during lifting. If you're uncertain, err on the side of caution and use a shackle with a higher WLL.

### **3.2. Inspection Before Use**

- Inspect shackles for wear, corrosion, cracks, or deformation.

- Ensure that the pin is secure and does not have any signs of wear.

- Confirm that the shackle has a clear and legible identification tag showing its WLL.

### **3.3. Safety Factor**

- The safety factor should be at least 4:1 or as per local regulations. For lifting applications involving heavy or critical loads, a safety factor of 6:1 may be necessary.

### **3.4. Angle of Lift**

Always calculate and consider the angle at which the load is being lifted. Angles greater than 45° can significantly increase the tension on the shackles and should be avoided when possible. If an angle greater than 45° is unavoidable, use shackles rated for higher loads.

---

## **4. Example Calculation for D-Shackle and Bow Shackle**

### **Example 1: D-Shackle Load Calculation**

- **Shackle Breaking Strength (BS):** 50 tons

- **Safety Factor (SF):** 5:1

- **WLL = BS / SF**

- **WLL = 50 tons / 5**

- **WLL = 10 tons**

This means that the **D-shackle** can safely handle a **10-ton load**.

### **Example 2: Bow Shackle Load Calculation (with Sling Angle)**

- **Shackle Breaking Strength (BS):** 60 tons

- **Safety Factor (SF):** 5:1

- **Load = 20 tons**

- **Sling Angle (θ):** 30°

- **Tension = Load / cos(θ)**

- **Tension = 20 tons / cos(30°)**

- **Tension = 20 tons / 0.866**

- **Tension = 23.1 tons**

Thus, the bow shackle needs to handle **23.1 tons** of tension due to the sling angle. Therefore, the WLL of the shackle should be greater than **23.1 tons** for safe operation.

---

## **5. Summary**

- **D-shackles** are ideal for straight-line loads and have a higher strength-to-size ratio.

- **Bow shackles** are more suitable for multi-directional loads due to their wider shape.

- Always check the **WLL** of shackles before use and calculate load angles to determine correct tension.

- Use a **safety factor** (typically 4:1 or 6:1) to ensure that the shackles do not exceed their capacity during lifting operations.

- Regularly inspect shackles to ensure that they are free from wear and damage.

---

By following these guidelines, you ensure that your rigging operations are safe and compliant with the necessary regulations. Would you like further examples or assistance with a specific lifting scenario?

-

6:51:13

6:51:13

Akademiks

9 hours agoDay 2/30. Nipsey Hussle Brother Standing on Bizniz? Offset and Cardi Calls it Quits. 50 v Jim Jones?

104K6 -

5:24:38

5:24:38

EricJohnPizzaArtist

9 hours agoAwesome Sauce PIZZA ART LIVE Ep. #37: Chaos in Roswell!

51K5 -

2:11:29

2:11:29

vivafrei

19 hours agoEp. 253: Zelensky Dress-Down and Geopolitical Fallout! D.C. Court Rules AGAINST Trump Firing & MORE!

196K302 -

2:13:14

2:13:14

Nerdrotic

12 hours ago $10.30 earnedMegalithomania! with Hugh Newman and Andrew Collins | Forbidden Frontier #092

86.8K11 -

38:41

38:41

Sarah Westall

13 hours agoHealth Freedom Under Attack, Dr Robert Young Found Guilty on Suspicious Victimless Crime, Matt Hazen

91K9 -

LIVE

LIVE

Vigilant News Network

12 hours agoDataRepublican Exposes the Shadow Government’s Darkest Secrets - Exclusive Interview | Media Blackout

2,028 watching -

31:39

31:39

Peter Santenello

1 year agoStories From Vegas' Golden Era 🇺🇸

88.1K24 -

LIVE

LIVE

The Why Files

16 hours agoLIVE: The Why Files 24/7 Stream n' Chat

1,376 watching -

55:15

55:15

Russell Brand

1 day agoThe Truth About Big Pharma & COVID with Dr. Aseem Malhotra

191K11 -

1:19:48

1:19:48

The Rubin Report

16 hours agoWhat the Trump Administration Must Do Instead of Revenge | Peter Thiel

143K173