Premium Only Content

CIP vs. COP- Cleaning Methods in the Food Industry │ Food Safety

Here’s a detailed comparison of **CIP (Clean-in-Place)** and **COP (Clean-out-of-Place)** cleaning methods commonly used in the food industry:

---

## **CIP vs. COP: Cleaning Methods in the Food Industry**

### **1. Overview of CIP and COP**

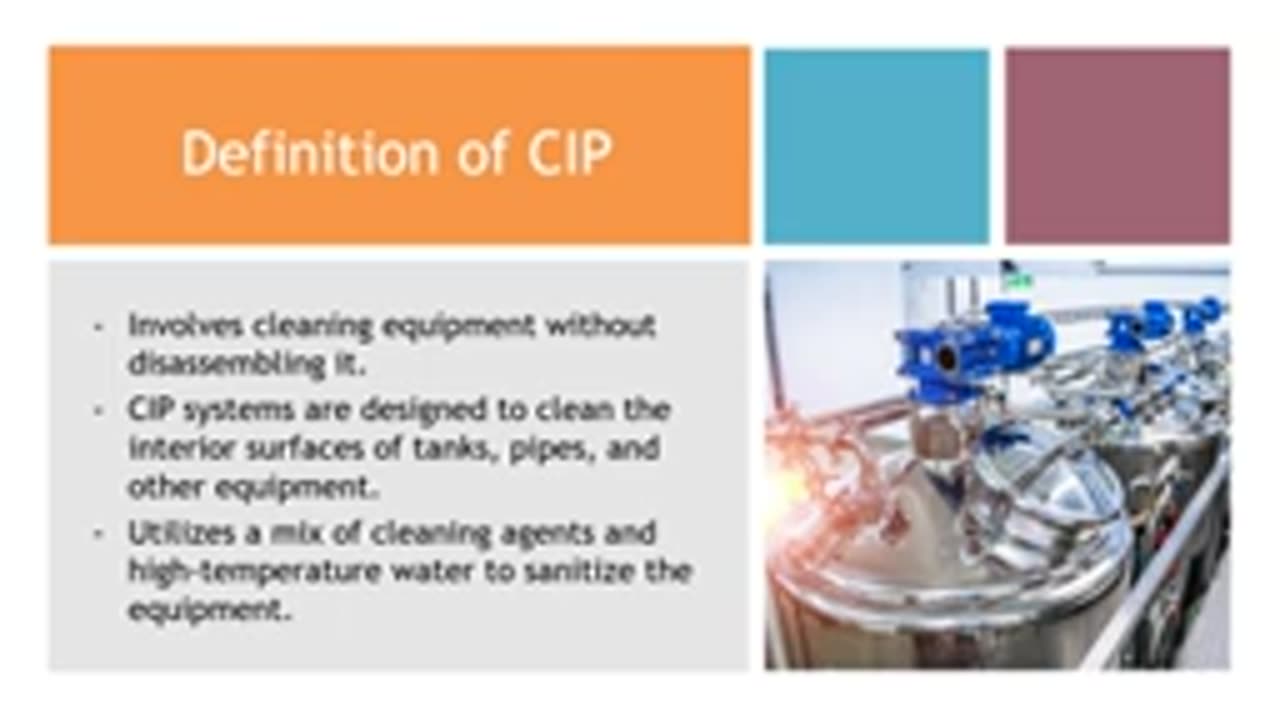

**CIP (Clean-in-Place):**

- A method where equipment is cleaned without disassembly.

- Cleaning agents (water, detergents, or sanitizers) are circulated through the system, such as pipes, tanks, and heat exchangers.

- Commonly used for large, complex, or fixed systems.

**COP (Clean-out-of-Place):**

- A method where equipment is disassembled, and individual parts are cleaned separately.

- Components are typically soaked, scrubbed, or cleaned in a dedicated cleaning station or tank.

- Suitable for small, removable, or intricate parts.

---

### **2. Key Differences Between CIP and COP**

| **Feature** | **CIP (Clean-in-Place)** | **COP (Clean-out-of-Place)** |

|------------------------------|------------------------------------------|-----------------------------------------|

| **Application** | Fixed systems (pipes, tanks, mixers) | Removable parts (filters, valves, utensils) |

| **Cleaning Process** | Automated or semi-automated cleaning | Manual cleaning or in specialized tanks |

| **Disassembly Required** | No | Yes |

| **Labor Intensity** | Low (automated process) | High (manual handling required) |

| **Water/Detergent Use** | Optimized (closed-loop system) | Higher due to manual scrubbing |

| **Suitability for Complex Equipment** | High | Limited |

| **Time Efficiency** | Faster | Slower |

| **Validation and Monitoring**| Easy (automated sensors for verification)| Manual inspection required |

| **Common Industries** | Dairy, beverage, brewing, pharmaceutical | Bakeries, meat processing, small-scale production |

---

### **3. CIP: Process and Advantages**

#### **CIP Process**

1. **Pre-Rinse:** Removes loose soil or residues with water.

2. **Detergent Wash:** Circulates cleaning chemicals to remove biofilms, fats, or proteins.

3. **Intermediate Rinse:** Removes detergent residues.

4. **Sanitization:** Uses heat or chemicals to sanitize equipment.

5. **Final Rinse (Optional):** Ensures no residual chemicals remain.

#### **Advantages of CIP:**

- **Consistency:** Ensures repeatable and thorough cleaning.

- **Efficiency:** Reduces cleaning time and labor costs.

- **Safety:** Minimizes worker exposure to chemicals or hazardous areas.

- **Environmental Benefits:** Lower water and chemical usage compared to manual cleaning.

#### **Challenges of CIP:**

- High initial installation and equipment costs.

- Requires skilled personnel for system maintenance.

---

### **4. COP: Process and Advantages**

#### **COP Process**

1. **Disassemble Equipment:** Remove parts for cleaning.

2. **Pre-Soak:** Submerge components in cleaning agents to loosen debris.

3. **Manual Cleaning:** Scrub, brush, or use agitation to clean thoroughly.

4. **Rinse and Sanitize:** Rinse with water and sanitize to eliminate microbes.

5. **Inspect and Reassemble:** Ensure cleanliness before reassembly.

#### **Advantages of COP:**

- **Flexibility:** Ideal for small or intricate components.

- **Customization:** Allows focused cleaning of specific areas.

- **Lower Initial Costs:** No need for specialized automated systems.

#### **Challenges of COP:**

- Labor-intensive and time-consuming.

- Higher water and detergent usage.

- Risk of incomplete cleaning if parts are missed or improperly reassembled.

---

### **5. When to Use CIP vs. COP**

#### **CIP is Best Suited For:**

- Large-scale production facilities.

- Equipment that is difficult to disassemble.

- Systems requiring frequent cleaning cycles (e.g., dairy, beverage plants).

#### **COP is Best Suited For:**

- Small-scale or batch production.

- Parts that are easily removable and require detailed cleaning.

- Facilities with budget constraints for automation.

---

### **6. Regulatory Requirements and Validation**

Both CIP and COP must comply with food safety standards, including:

- **HACCP:** Cleaning must address critical control points to prevent contamination.

- **FDA and USDA Guidelines:** Mandate sanitation practices for food contact surfaces.

- **Validation:**

- **CIP:** Automated systems often have sensors and software for monitoring flow rates, temperature, and chemical concentration.

- **COP:** Requires manual inspection and swab testing to verify cleanliness.

---

### **7. Conclusion**

The choice between CIP and COP depends on the facility's needs, the type of equipment, production scale, and budget. While CIP offers efficiency and consistency for larger systems, COP is practical for smaller or specialized parts that require detailed cleaning. Both methods play a crucial role in ensuring food safety, maintaining equipment performance, and meeting regulatory requirements.

---

Would you like to develop a more detailed protocol or SOP for CIP or COP in your operation?

-

6:54

6:54

HSESafetyInformation

8 days ago6 Must Try Breakfast recipes By Food Fusion

201 -

44:39

44:39

Kimberly Guilfoyle

4 hours agoBetter Days Ahead for the FBI, Live with Asm Bill Essayli & John Koufos | Ep.199

43.1K23 -

1:40:29

1:40:29

In The Litter Box w/ Jewels & Catturd

1 day agoWhat Did You Do Last Week? | In the Litter Box w/ Jewels & Catturd – Ep. 748 – 2/24/2025

76.6K30 -

23:34

23:34

Stephen Gardner

4 hours ago🔥CNN PANICS over $5000 DOGE Dividend | Trump Orders bigger Audits

35.7K107 -

1:53:54

1:53:54

The White House

6 hours agoPresident Trump Holds a Press Conference with President Emmanuel Macron of France

60.5K40 -

1:48:31

1:48:31

The Officer Tatum

6 hours agoLIVE MSNBC DROPS HAMMER On Joy Reid as STAFFERS PANIC! + More Ep 67

107K69 -

59:36

59:36

Chad Prather

5 hours agoTRUMP TAPS DAN BONGINO TO HELP LEAD FBI - IT’S OVER FOR THE DEEP STATE!

70.1K61 -

4:18:28

4:18:28

Barry Cunningham

11 hours agoTRUMP DAILY BRIEFING: DAN BONGINO TO FBI | LIVE PRESS CONFERENCE WITH MACRON | DOGE MELTDOWN!

61.6K20 -

2:08:16

2:08:16

Mike Rowe

3 days agoTim Allen Loves The Ballet | The Way I Heard It with Mike Rowe

58.3K21 -

1:42:25

1:42:25

Russell Brand

10 hours agoWar, Wokeism & Wealth: The Forces Reshaping Our World – SF542

154K97