Premium Only Content

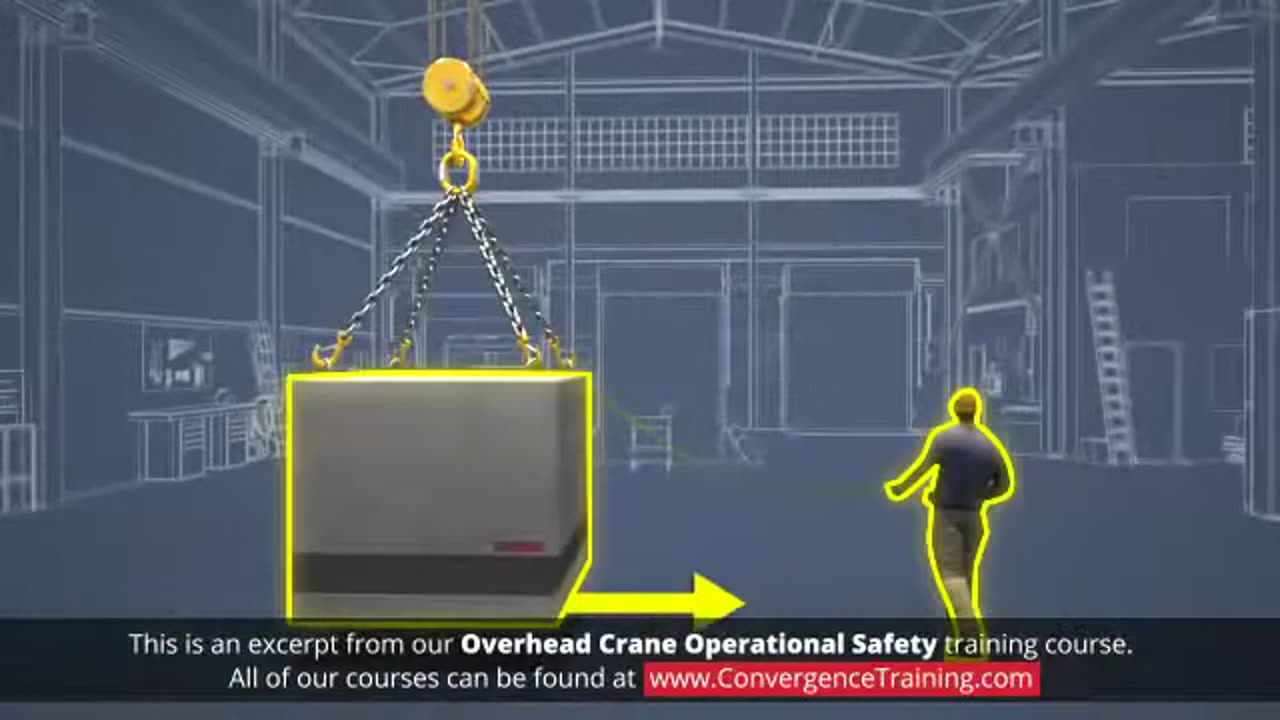

Overhead Crane Operational Safety for Canada

Operating overhead cranes in Canada requires strict adherence to safety protocols as outlined in federal and provincial regulations. Here's a summary of key considerations for overhead crane operational safety:

---

### **1. Regulatory Standards**

- **Canadian Standards Association (CSA):** The CSA has specific standards for cranes, including **CSA B167-16** (Safety Standard for Overhead Cranes, Gantry Cranes, and Monorails).

- **Occupational Health and Safety (OHS):** Provincial OHS laws regulate the operation, inspection, and maintenance of overhead cranes.

- **Workplace Hazardous Materials Information System (WHMIS):** Operators must be aware of WHMIS protocols when working near hazardous materials.

---

### **2. Operator Requirements**

- **Training and Certification:**

- Operators must complete a certified crane operation training program.

- Familiarity with equipment-specific controls and load limits is essential.

- **Medical Fitness:**

- Operators should meet medical and vision standards to safely operate the crane.

- **Knowledge of Signals:**

- Operators must understand standard hand signals used for crane operation.

---

### **3. Pre-Operational Safety Checks**

- **Visual Inspection:**

- Inspect for wear and tear on cables, hooks, and structural components.

- Check for leaks, loose bolts, or mechanical issues.

- **Functionality Tests:**

- Test the brakes, emergency stop, and other controls before operation.

- **Load Limit Verification:**

- Ensure the load does not exceed the crane’s rated capacity.

---

### **4. Safe Operational Practices**

- **Load Handling:**

- Center the load directly under the crane hook.

- Avoid sudden movements like jerking or swinging.

- **Prohibited Actions:**

- Never carry loads over personnel.

- Avoid side-pulling or dragging the load.

- **Communication:**

- Maintain clear communication with the ground crew using hand signals or radios.

---

### **5. Emergency Preparedness**

- Operators must know:

- Emergency stop procedures.

- Protocols for power failure or mechanical breakdown.

---

### **6. Maintenance and Inspections**

- **Daily Inspections:**

- Conduct pre-use and post-use checks.

- **Periodic Maintenance:**

- Follow manufacturer-recommended schedules.

- Engage qualified professionals for repairs and advanced inspections.

---

### **7. Environmental Considerations**

- Avoid operations in extreme weather conditions like high winds or freezing rain unless equipment is rated for it.

---

### **8. Documentation**

- Maintain detailed records of inspections, maintenance, and operator certifications.

---

Let me know if you'd like a specific checklist or further details on any of these points!

-

1:00:46

1:00:46

The StoneZONE with Roger Stone

5 hours agoFake News Attack on Tulsi Gabbard! | The StoneZONE w/ Roger Stone

29.6K12 -

2:24:08

2:24:08

WeAreChange

8 hours agoElon Musk & Donald Trump: The Emergency Halt That Saved Us

64K55 -

1:13:11

1:13:11

Flyover Conservatives

1 day agoWARNING! Is Bitcoin CIA-Controlled? – The Shocking Reality of Digital Assets - Clay Clark | FOC Show

23.8K6 -

2:00:37

2:00:37

Space Ice

11 hours agoSpace Ice & Redeye Try To Figure Out Seagal's Most Incoherent Movie

79.3K2 -

1:00:36

1:00:36

PMG

1 day ago $6.29 earned"Santa Trump is Giving Us Hope - But Will Johnson Stand Strong?"

71.5K12 -

54:30

54:30

LFA TV

1 day agoThe German Strongman’s Arrival Is Imminent | Trumpet Daily 12.18.24 7PM EST

56.2K3 -

2:04:11

2:04:11

Melonie Mac

9 hours agoGo Boom Live Ep 32! Soul Reaver Remastered!

46.4K9 -

39:11

39:11

Sarah Westall

6 hours agoDigital Slavery and Playing with Fire: Money, Banking, and the Federal Reserve w/ Tom DiLorenzo

56.4K4 -

1:38:38

1:38:38

2 MIKES LIVE

11 hours ago2 MIKES LIVE #157 ILLEGALS, PROTESTORS AND DRONES!

38K1 -

1:01:03

1:01:03

LFA TV

1 day agoTHE LATEST SPENDING BILL IS AN ABOMINATION! | UNGOVERNED 12.18.24 5pm EST

40.4K47