Premium Only Content

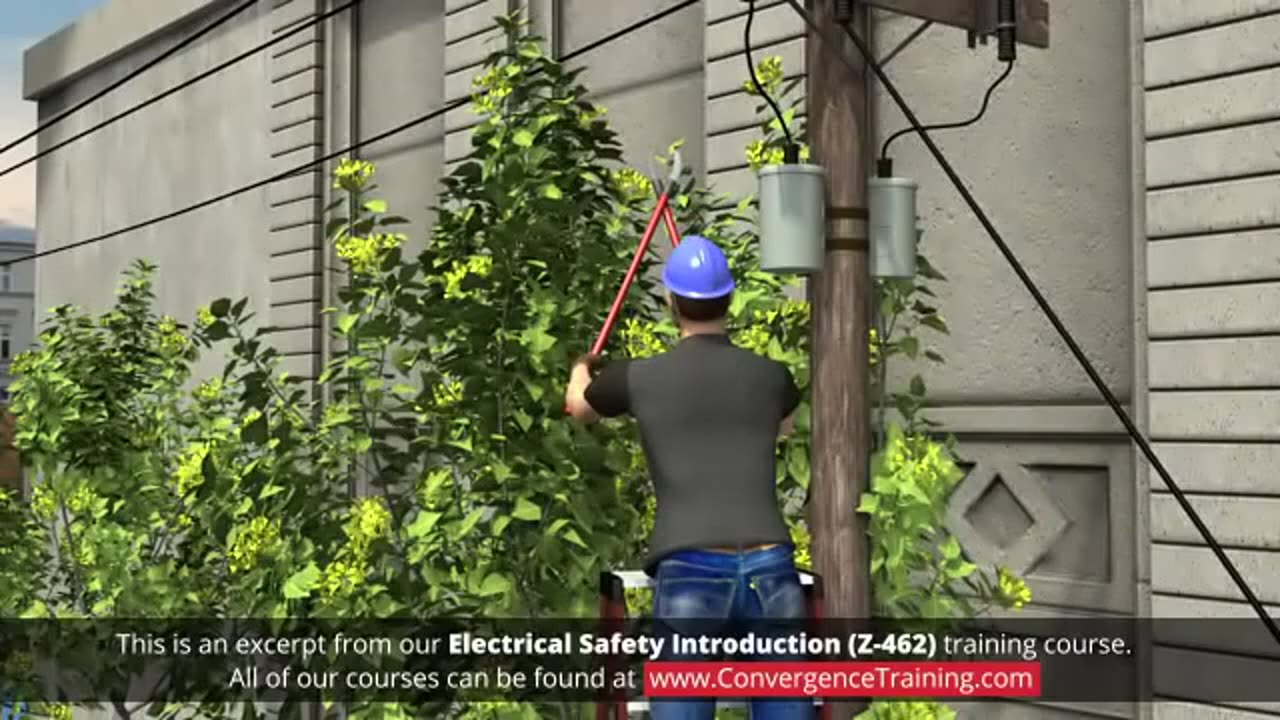

Electrical Safety Introduction (Z-462) for Canada

### **Electrical Safety Introduction (CSA Z462) for Canada**

Electrical safety is critical in workplaces across Canada, especially for those working with or near electrical equipment. The **CSA Z462 Standard: Workplace Electrical Safety** provides comprehensive guidance to protect workers from electrical hazards such as shock, arc flash, and arc blast. It aligns with the **NFPA 70E** in the United States and is an essential framework for developing and implementing electrical safety programs in Canadian workplaces.

---

### **What is CSA Z462?**

The **CSA Z462** is a Canadian standard that sets out best practices for electrical safety in the workplace. It includes requirements for:

- Hazard identification and risk assessment.

- Safe work practices for energized and de-energized electrical work.

- Selection and use of personal protective equipment (PPE).

- Electrical equipment maintenance and documentation.

---

### **Purpose of CSA Z462**

The primary goals of the CSA Z462 standard are to:

1. **Protect Workers**:

- Minimize the risk of injury or fatality from electrical hazards.

2. **Provide Guidance**:

- Establish consistent, best-practice procedures for electrical safety.

3. **Facilitate Compliance**:

- Help employers meet provincial/territorial occupational health and safety requirements.

---

### **Key Components of CSA Z462**

The standard is built around **three key areas**: hazard identification, risk assessment, and control measures.

---

#### **1. Hazard Identification**

The primary electrical hazards addressed by CSA Z462 include:

- **Electrical Shock**:

- Contact with live conductors can result in severe injury or death.

- **Arc Flash**:

- A sudden release of electrical energy caused by a fault or short circuit.

- Produces intense heat, light, and pressure, leading to burns or other injuries.

- **Arc Blast**:

- A violent explosion caused by the rapid expansion of gases during an arc flash.

- **Fire and Explosion**:

- Sparks or arcs igniting flammable materials.

---

#### **2. Risk Assessment**

CSA Z462 emphasizes the importance of conducting a **risk assessment** before performing electrical work. This involves:

1. **Identifying Hazards**:

- Determine the presence of shock and arc flash risks.

2. **Assessing Risks**:

- Evaluate the likelihood and severity of injury.

3. **Implementing Controls**:

- Apply controls to reduce risks, such as de-energizing equipment or using PPE.

---

#### **3. Control Measures**

The standard promotes the **Hierarchy of Risk Control**, which prioritizes eliminating hazards wherever possible:

1. **Elimination**:

- De-energize equipment before starting work (preferred method).

2. **Substitution**:

- Use safer equipment or systems.

3. **Engineering Controls**:

- Install barriers, grounding systems, and arc-resistant equipment.

4. **Administrative Controls**:

- Develop and enforce safe work practices and procedures.

5. **Personal Protective Equipment (PPE)**:

- Provide appropriate PPE, including arc-rated clothing, gloves, and face shields.

---

### **Key Requirements of CSA Z462**

1. **Establish an Electrical Safety Program**:

- Employers must create and implement a formal electrical safety program that includes hazard identification, procedures, and training.

2. **Perform Hazard Analysis**:

- Conduct an **Arc Flash Hazard Analysis** to calculate incident energy levels (measured in cal/cm²) and define arc flash boundaries.

3. **Label Electrical Equipment**:

- Equipment must display arc flash and shock warning labels, including:

- Incident energy or PPE category.

- Arc flash boundary.

- Nominal voltage.

4. **De-Energized Work**:

- De-energize equipment wherever possible to eliminate electrical hazards.

5. **Energized Work Permit**:

- If energized work is unavoidable, workers must follow strict protocols, including obtaining a written permit.

6. **Use of PPE**:

- Workers must wear appropriate PPE based on the incident energy levels identified during hazard analysis.

7. **Training Requirements**:

- Workers must be trained to recognize electrical hazards and perform work safely.

8. **Maintenance of Electrical Equipment**:

- Regular maintenance is required to reduce the likelihood of electrical faults.

---

### **Arc Flash Safety in CSA Z462**

Arc flash is a significant focus of CSA Z462 due to its potential for catastrophic injuries. Key provisions include:

1. **Arc Flash Risk Assessment**:

- Determine the incident energy at each piece of electrical equipment.

- Define the **Arc Flash Boundary**—the distance within which PPE is required.

2. **Incident Energy Analysis**:

- Calculate the energy released in an arc flash to determine the level of protection needed.

3. **PPE Requirements**:

- Workers must wear arc-rated clothing and PPE suited to the calculated incident energy.

---

### **PPE Categories**

CSA Z462 defines PPE categories based on incident energy levels:

- **Category 1 (4 cal/cm²)**: Basic protection, such as arc-rated clothing and face shields.

- **Category 2 (8 cal/cm²)**: Increased protection with additional layers.

- **Category 3 (25 cal/cm²)**: Higher-rated clothing and equipment.

- **Category 4 (40 cal/cm²)**: The highest level of protection for severe hazards.

---

### **Training Requirements**

Training is a critical component of CSA Z462. Workers must:

1. **Understand Electrical Hazards**:

- Learn about shock, arc flash, and other risks.

2. **Know Safe Work Practices**:

- Be trained on procedures for de-energizing equipment, lockout/tagout, and proper use of PPE.

3. **Emergency Response**:

- Know how to respond to electrical accidents and perform first aid (e.g., CPR).

---

### **Documentation and Recordkeeping**

Employers must maintain:

- Records of risk assessments, hazard analyses, and equipment maintenance.

- Training records for all workers involved in electrical work.

- Energized work permits, where applicable.

---

### **Integration with Provincial and Territorial Regulations**

CSA Z462 helps employers comply with **provincial/territorial OHS regulations** by providing a structured approach to managing electrical safety. For example:

- Ontario’s **Occupational Health and Safety Act (OHSA)** requires hazard identification and control measures for electrical work.

- Alberta’s **OHS Code** mandates adherence to recognized standards, like CSA Z462, for safe electrical practices.

---

### **Penalties for Non-Compliance**

Failure to comply with CSA Z462 and provincial regulations can result in:

- Fines and penalties from OHS authorities.

- Increased liability for workplace injuries or fatalities.

- Damage to company reputation and worker trust.

---

### **Conclusion**

CSA Z462 provides a robust framework for managing electrical safety in Canadian workplaces. By following its guidelines, employers and workers can significantly reduce the risk of injuries or fatalities caused by electrical hazards. Key steps include performing risk assessments, implementing control measures, providing proper training, and ensuring the use of appropriate PPE. A proactive approach to electrical safety not only ensures compliance but also fosters a culture of safety and accountability.

-

1:35

1:35

HSESafetyInformation

3 days agoMutton Chops two ways- baked & grilled Recipe by Food Fusion (Eid Recipe)

27 -

55:52

55:52

LFA TV

1 day agoTrump vs. Europe | TRUMPET DAILY 2.20.25 7PM

7.85K2 -

31:02

31:02

Chrissy Clark

2 hours agoAn IVF Nightmare, Trump’s Illegal Immigration Crackdown, & Biden’s Student Loan Plan BLOCKED I URS

14.1K6 -

1:02:57

1:02:57

In The Litter Box w/ Jewels & Catturd

1 day agoKASH CONFIRMATION TODAY! | In the Litter Box w/ Jewels & Catturd – Ep. 746 – 2/20/2025

99.7K71 -

56:44

56:44

VSiNLive

4 hours ago $5.49 earnedFollow the Money with Mitch Moss & Pauly Howard | Hour 1

88.2K3 -

1:08:41

1:08:41

John Crump Live

8 hours ago $2.49 earnedUSA v. Canada! Bigger Than Just A Game

41.4K6 -

1:58:40

1:58:40

Revenge of the Cis

5 hours agoEpisode 1450: Wet Work

52.1K3 -

3:36:29

3:36:29

vivafrei

11 hours agoKash Patel Confirmation Hearing LIVE! Jan. 6'er Kicked Out of CPAC? DOGE Wins in Court? & MORE!

270K297 -

5:08:38

5:08:38

Barry Cunningham

11 hours agoTRUMP DAILY BRIEFING: KASH PATEL VOTE | WHITE HOUSE PRESS CONFERENCE | DOGE UPDATE

73.3K28 -

1:57:54

1:57:54

The Quartering

9 hours agoRand Paul Praises Trump, Amazon Takes Control of Bond, and Delta Gives Passengers $30,000

124K40