Premium Only Content

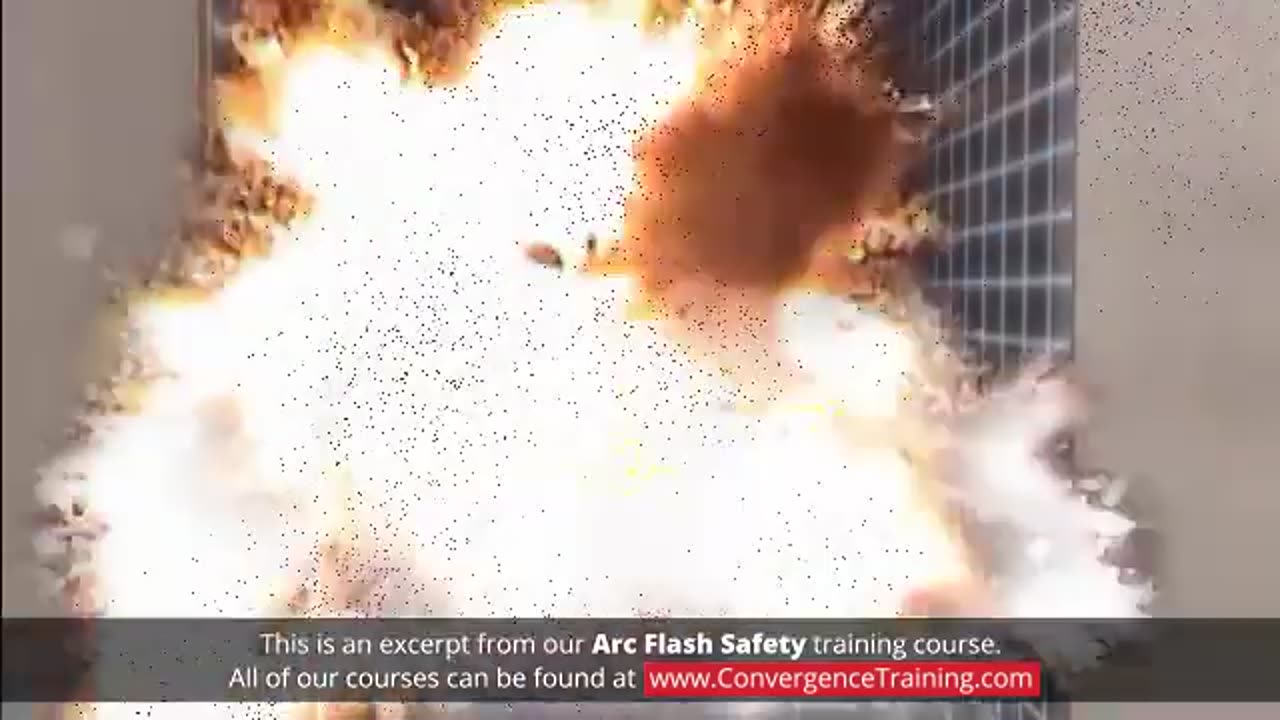

Arc Flash Safety for Canada

**Arc Flash Safety** in Canada is a critical aspect of electrical safety management. Arc flashes, which result from sudden releases of electrical energy due to a fault or short circuit, can cause severe burns, injuries, or fatalities. Canadian workplaces follow specific regulations and standards to protect workers from arc flash hazards. Here's an overview of **Arc Flash Safety** in Canada:

---

### **What is an Arc Flash?**

An arc flash is a violent release of energy caused by an electrical fault that:

- Produces intense heat (up to 20,000°C, hotter than the surface of the sun).

- Expels molten metal, creates a pressure wave, and generates bright light and sound.

- Can result in serious injuries, burns, or even fatalities for workers nearby.

---

### **Regulations and Standards in Canada**

Arc flash safety in Canada is regulated by a combination of **provincial/territorial occupational health and safety (OHS) regulations** and national standards. Key references include:

1. **Provincial/Territorial OHS Acts and Regulations**:

- Each province and territory in Canada has its own occupational health and safety legislation, which generally mandates that employers ensure the health and safety of workers, including protection from electrical hazards.

2. **CSA Standards**:

- **CSA Z462: Workplace Electrical Safety**:

- The primary standard for arc flash safety in Canada.

- Provides guidance for electrical safety practices and procedures to protect workers from electrical hazards.

- Aligns with the **NFPA 70E** standard used in the U.S.

- Includes requirements for risk assessments, arc flash hazard analysis, and personal protective equipment (PPE).

- **CSA Z463: Maintenance of Electrical Systems**:

- Supports Z462 by focusing on the maintenance of electrical equipment to reduce arc flash risks.

- **CSA Z94.3: Eye and Face Protectors**:

- Governs the design, testing, and use of eye and face protection, including those needed for arc flash hazards.

---

### **Key Requirements for Arc Flash Safety**

To comply with Canadian regulations and standards, employers must implement comprehensive arc flash safety programs. These programs should include the following steps:

---

#### **1. Conducting an Arc Flash Risk Assessment**

- A **risk assessment** must be performed to:

- Identify potential arc flash hazards.

- Determine the level of risk for specific tasks or equipment.

- Establish safe work practices and controls.

- **Arc Flash Hazard Analysis**:

- Calculate the incident energy (measured in calories per square centimeter, or cal/cm²) to determine the potential severity of exposure.

- Define the **Arc Flash Boundary**: The distance within which workers may be exposed to hazardous energy.

---

#### **2. Labeling Electrical Equipment**

- All equipment that may pose an arc flash risk must have proper labeling that includes:

- Incident energy or required PPE level.

- Arc Flash Boundary.

- Nominal voltage of the equipment.

---

#### **3. Training for Workers**

- Workers exposed to electrical hazards must receive **training** that includes:

- Arc flash hazards and effects.

- Safe work practices, including lockout/tagout procedures.

- Understanding of arc flash labels and PPE requirements.

- Emergency response in case of an arc flash incident.

---

#### **4. Providing Personal Protective Equipment (PPE)**

- Employers must supply appropriate PPE based on the incident energy level determined in the risk assessment.

- PPE includes:

- Arc-rated clothing (shirts, pants, coveralls, jackets).

- Arc-rated face shields or hoods.

- Insulated gloves and footwear.

- Ear and eye protection.

- PPE must meet the performance requirements of **CSA Z462** and **CSA Z94.1 (Industrial Protective Headwear)**.

---

#### **5. Establishing Safe Work Practices**

- Develop and enforce procedures for working near or on live electrical equipment, including:

- **De-energizing Equipment**: Wherever possible, equipment should be de-energized before performing work.

- **Live Work Permits**: If live work is necessary, follow strict procedures with written permits.

- **Establishing Boundaries**:

- **Arc Flash Boundary**: Distance where PPE is required.

- **Limited Approach Boundary**: Distance where unqualified workers must stay clear.

- **Restricted Approach Boundary**: Distance where only qualified workers with appropriate PPE can enter.

---

#### **6. Maintaining Electrical Equipment**

- Proper **maintenance** of electrical systems reduces the likelihood of faults and arc flash incidents.

- Follow CSA Z463 standards for preventive and predictive maintenance.

---

### **Employer Responsibilities**

Under Canadian law, employers must:

1. **Identify Hazards**: Perform risk assessments to identify arc flash and other electrical hazards.

2. **Control Risks**: Use engineering controls (e.g., arc-resistant equipment), administrative controls (e.g., safe work procedures), and PPE to minimize risks.

3. **Provide Training**: Ensure workers are trained and competent in electrical safety and arc flash procedures.

4. **Monitor Compliance**: Regularly audit and review safety programs to ensure ongoing compliance with standards.

---

### **Worker Responsibilities**

Workers have responsibilities to:

- Follow safety procedures and guidelines outlined by their employer.

- Use PPE properly and report damaged or inadequate equipment.

- Report unsafe conditions or practices to their supervisor.

- Participate in training and apply learned safety measures.

---

### **Penalties for Non-Compliance**

Failure to comply with arc flash safety regulations can lead to:

- Fines and penalties from provincial OHS authorities.

- Increased liability for workplace injuries or fatalities.

- Negative impact on company reputation and worker morale.

---

### **Conclusion**

Arc flash safety in Canada is a shared responsibility between employers and workers. Following the CSA Z462 standard and provincial OHS regulations ensures that proper safeguards, training, and PPE are in place to reduce the risks associated with arc flash incidents. A proactive approach not only protects lives but also helps organizations maintain compliance and a culture of safety.

-

1:52:24

1:52:24

Kim Iversen

13 hours agoLuigi Mangione Charged With TERRORISM | Liz Cheney Accused Of WITNESS TAMPERING, Faces 20 YEARS IN JAIL

119K159 -

6:50:10

6:50:10

Akademiks

14 hours agoJay Z says he aint NEVER been friends w/ DIDDY! Bhad Bhabie lost her man? Travis Hunter Down Bad?

121K14 -

2:27:04

2:27:04

AirCondaTv Gaming

12 hours ago $24.26 earnedWar Thunder - Tankering Around for That 10 Bomb

63.1K5 -

4:19:05

4:19:05

SpartakusLIVE

15 hours agoThe MACHINE locks in for 12-hour POWER stream

45.1K1 -

1:58:40

1:58:40

Robert Gouveia

14 hours agoJ6 Coverup: Prosecute LIZ CHENEY; NY Judge REJECTS Immunity; Trump Breaks Gag?

179K94 -

2:22:06

2:22:06

WeAreChange

13 hours agoPSYOP Spreads: Drones Shut Down Airport In New York!

115K52 -

1:31:18

1:31:18

Redacted News

15 hours agoEMERGENCY! NATO AND CIA ASSASSINATE TOP RUSSIAN GENERAL, PUTIN VOWS IMMEDIATE RETALIATION | Redacted

254K600 -

56:45

56:45

VSiNLive

14 hours ago $7.35 earnedFollow the Money with Mitch Moss & Pauly Howard | Hour 1

90.9K2 -

52:44

52:44

Candace Show Podcast

14 hours agoMy Conversation with Only Fans Model Lilly Phillips | Candace Ep 122

119K383 -

5:47:55

5:47:55

tacetmort3m

15 hours ago🔴 LIVE - RELIC HUNTING CONTINUES - INDIANA JONES AND THE GREAT CIRCLE - PART 5

57.5K