Premium Only Content

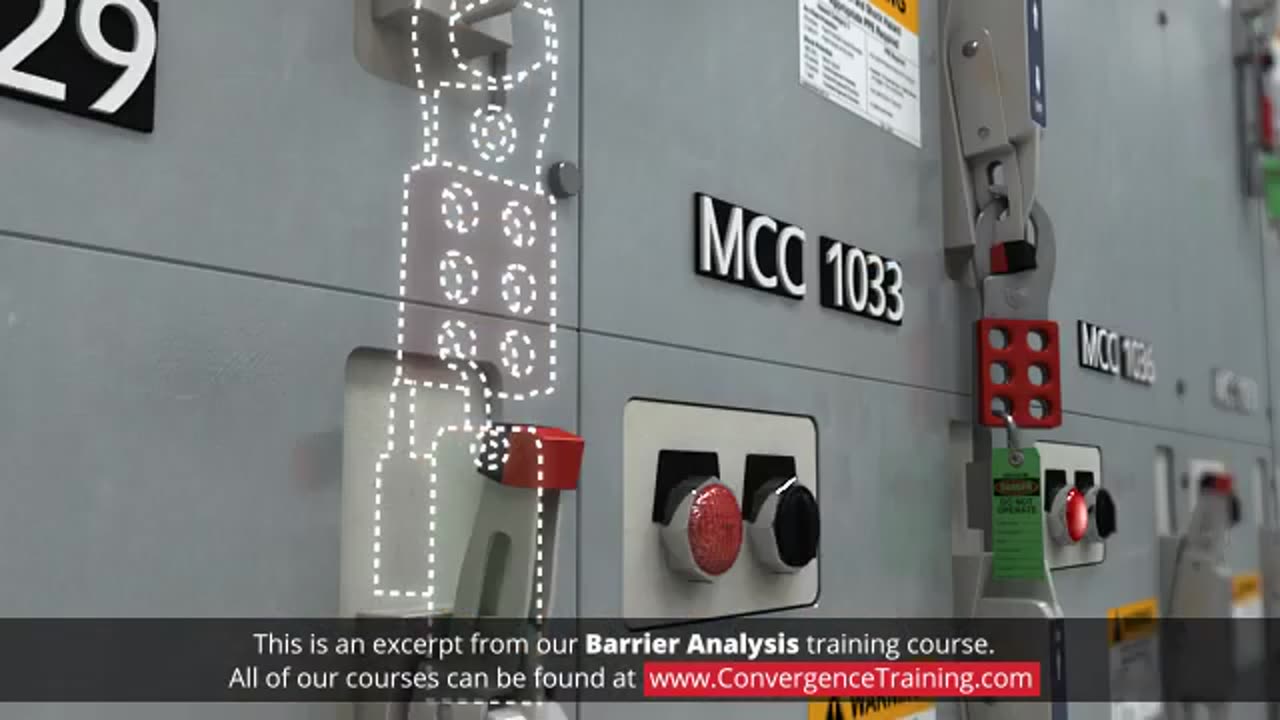

How to Perform a Barrier Analysis

**Barrier Analysis** is a powerful technique used to identify and evaluate the barriers that could prevent an accident or hazard from occurring. It is widely used in safety management, root cause analysis, and risk assessment processes. Below is a step-by-step guide to performing a **Barrier Analysis**:

---

### **Step 1: Define the Problem or Incident**

- Clearly state the problem, accident, or undesired event you are analyzing.

- Include key information such as:

- What happened (or could happen)?

- When and where did it occur (or might it occur)?

- Who or what was involved?

---

### **Step 2: Identify the Hazards**

- Pinpoint the potential or actual hazards associated with the event or process.

- **Example:** A chemical spill poses hazards like toxic fumes, environmental contamination, or physical harm.

---

### **Step 3: Identify the Targets**

- Determine who or what is at risk from the hazard (the "target").

- **Example:** Workers, the public, the environment, or equipment could be targets.

---

### **Step 4: Identify the Barriers**

- List all existing or potential barriers that can prevent the hazard from reaching the target. Barriers are measures, controls, or safeguards designed to:

- Eliminate the hazard.

- Reduce the likelihood of occurrence.

- Minimize the severity of consequences.

Barriers can be categorized into:

1. **Physical Barriers**: Fences, protective equipment, containment systems, etc.

2. **Procedural Barriers**: Safety protocols, checklists, training, etc.

3. **Administrative Barriers**: Rules, permits, signage, management controls, etc.

4. **Human Barriers**: Actions of trained personnel or operators.

- **Example:** For a chemical spill, barriers could include spill containment systems, emergency response plans, and proper PPE.

---

### **Step 5: Evaluate the Barriers**

- Assess each barrier's **effectiveness** in preventing the hazard or mitigating its consequences:

1. **Are the barriers adequate?** Check their design, implementation, and maintenance.

2. **Are there gaps or weaknesses?** Determine if any barriers are missing, poorly implemented, or failing.

3. **Are barriers independent?** Consider whether multiple barriers rely on the same factor (common cause failure).

---

### **Step 6: Analyze Barrier Failures (if applicable)**

- If an incident occurred, evaluate how barriers failed or were bypassed. Ask:

- Were the barriers properly implemented?

- Were the barriers maintained or tested regularly?

- Did human error or unexpected circumstances undermine the barriers?

---

### **Step 7: Propose Improvements or Additional Barriers**

- Based on your evaluation, identify new or enhanced barriers to address weaknesses.

- Consider redundancy: Add multiple layers of barriers for critical hazards.

- Address organizational and human factors: Ensure training, communication, and oversight are adequate.

---

### **Step 8: Document and Communicate Findings**

- Record the analysis in a clear and structured format for review and implementation.

- Use tools like **Barrier Diagrams** or **Bowtie Diagrams** to visually represent hazards, barriers, and their relationships.

- Communicate findings to all relevant stakeholders, including management and workers.

---

### **Step 9: Implement and Monitor Changes**

- Implement the recommended improvements and ensure they are integrated into safety management systems.

- Continuously monitor the barriers' performance and effectiveness through audits, inspections, and feedback.

---

### **Example of a Barrier Analysis**

#### Scenario: Chemical Spill in a Warehouse

1. **Hazard**: Hazardous chemical leak.

2. **Target**: Workers, environment, and equipment.

3. **Existing Barriers**:

- Spill containment trays (physical).

- Regular safety training (procedural).

- Emergency response plan (administrative).

4. **Weakness Identified**:

- Training not updated for new employees.

- Containment trays were damaged and not replaced.

5. **Recommendations**:

- Schedule regular inspections of containment systems.

- Develop a robust onboarding training program for new hires.

- Add secondary barriers like automatic chemical shutoff valves.

---

Barrier Analysis is most effective when used as part of a broader risk assessment framework, such as **Root Cause Analysis (RCA)** or **Hazard Identification (HAZID).**

-

6:43

6:43

HSESafetyInformation

2 months agoLahori Chanay Recipe - Lahori Cholay Recipe - Chana Chana Masala

39 -

8:06:34

8:06:34

MyronGainesX

22 hours ago $22.64 earnedKarmelo Anthony Merch, Ashley EXPOSES Elon, Filipino President Punishes Vitaly, Iran War Pause!

59.8K12 -

2:41:54

2:41:54

TimcastIRL

7 hours agoMASS SHOOTING At Florida State, Anti Trump Rumors ERUPT, MANGIONE EFFECT w/ Maggie Moda| Timcast IRL

191K110 -

2:36:29

2:36:29

The Illusion of Consensus

1 day agoExploring Holistic Psychiatry with Dr. Aruna Tammala: Nervous System Regulation, Diet, Supplements, Self-love, and Social Connection

26K -

2:44:57

2:44:57

Laura Loomer

6 hours agoEP115: Democrats' Pet Muslims Bite Back

46.9K15 -

18:37

18:37

SantaSurfing

10 hours ago4/17/2025 - Trouble for Tish/Google/Jerome! Trump stops a war!

31.5K17 -

49:39

49:39

Man in America

14 hours agoThey’re Feeding Us POISON and Calling It Dinner w/ Kim Bright

51.1K16 -

3:40:07

3:40:07

BrancoFXDC

4 hours ago $2.74 earnedWarzone Rounds - DAY 10 of no Internet

30.9K2 -

1:17:17

1:17:17

RiftTV/Slightly Offensive

9 hours ago $11.21 earnedMASSACRE at FSU: Who was Actually RESPONSIBLE? | Slightly Offensive

48K17 -

3:18:46

3:18:46

SilverFox

6 hours ago🔴LIVE - HUGE UPDATE! LORDS OF THE FALLEN 2.0

29.9K