Premium Only Content

Hazardous Material Labeling

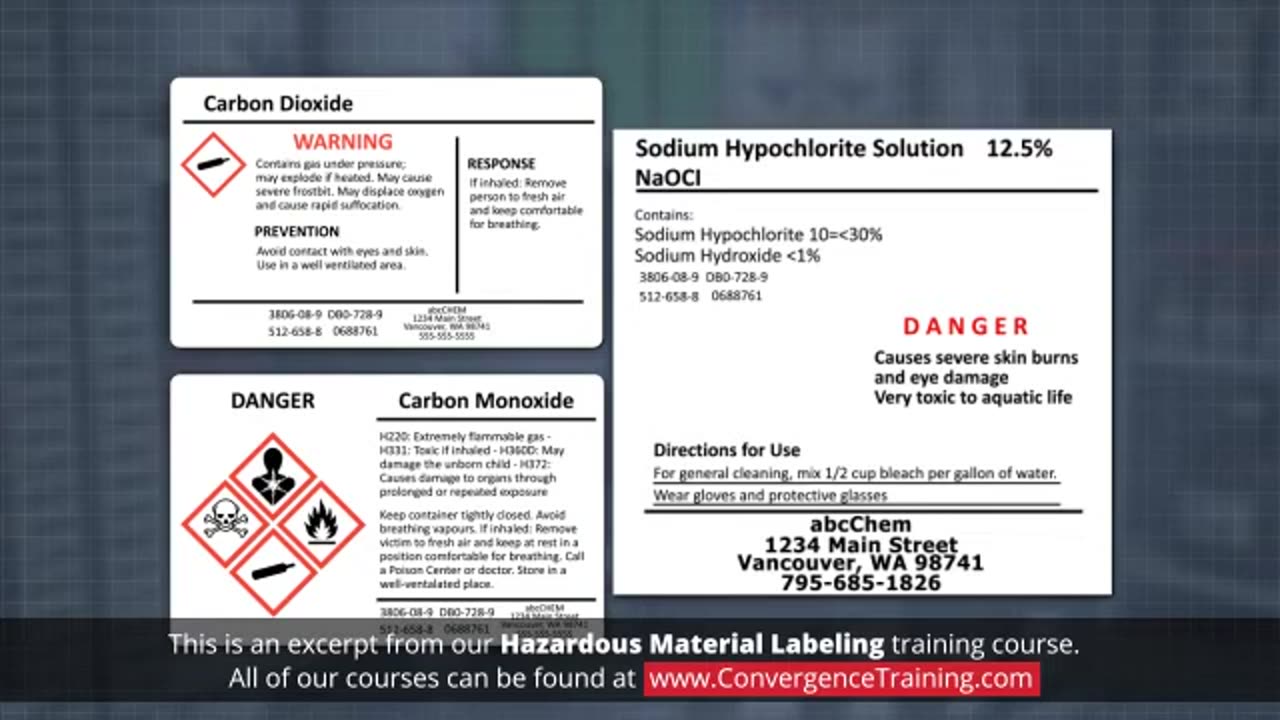

**Hazardous Material Labeling** is essential for ensuring safe handling, storage, and disposal of hazardous substances. Proper labeling provides critical information about the potential risks and how to safely interact with the material. Various standards and guidelines are used for labeling hazardous materials, including OSHA’s Hazard Communication Standard (HCS) and the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals.

### Key Elements of Hazardous Material Labeling:

1. **Label Components**:

- **Product Identifier**: A unique name or number used to identify the hazardous material.

- **Signal Words**: "Danger" (for more severe hazards) or "Warning" (for less severe hazards), used to indicate the severity of the hazard.

- **Hazard Statements**: Describes the nature of the hazard(s) associated with the material (e.g., "flammable liquid," "causes skin irritation").

- **Precautionary Statements**: Recommendations for safe handling, storage, and emergency measures (e.g., "Wear protective gloves," "Store in a well-ventilated area").

- **Pictograms**: Visual symbols that convey information about the hazards (e.g., a flame for flammability, a skull for toxicity).

2. **OSHA’s Hazard Communication Standard (HCS)**:

- Requires employers to ensure that all hazardous chemicals are properly labeled according to GHS standards.

- Labels must be legible, in English (and any other language spoken by employees), and prominently displayed on all containers of hazardous materials.

- Employers must also provide Safety Data Sheets (SDS) that give more detailed information about each substance.

3. **Globally Harmonized System (GHS)**:

- An international system for classifying and labeling chemicals, adopted by OSHA in 2012.

- GHS uses standardized symbols and a consistent color scheme for labels to make it easier for workers worldwide to understand the hazards of chemicals.

4. **NFPA (National Fire Protection Association) Labels**:

- The NFPA diamond system uses a color-coded label with numbers ranging from 0 (least hazardous) to 4 (most hazardous) for each of three categories: Health, Flammability, and Reactivity.

- This system is often used in industrial settings where hazardous materials are frequently handled or stored.

5. **Additional Considerations**:

- **Secondary Containers**: When hazardous materials are transferred from their original containers, secondary containers must also be labeled with the same information as the primary container.

- **Special Handling**: Materials with unique hazards (e.g., radioactive substances, corrosive acids) may require specific labeling formats or additional warnings.

### Importance of Proper Labeling:

- **Safety**: Reduces the risk of accidents and injuries by clearly communicating hazards to workers and emergency responders.

- **Compliance**: Ensures adherence to regulatory standards such as OSHA’s HCS, GHS, and NFPA requirements.

- **Emergency Response**: Provides vital information during accidents, spills, or exposures, enabling quicker and more effective responses.

For more detailed guidelines on labeling and specific compliance requirements, refer to OSHA's **Hazard Communication Standard** (29 CFR 1910.1200) and the **Globally Harmonized System of Classification and Labeling of Chemicals** (GHS). You can also consult the **NFPA guidelines** for more about their labeling system.

-

1:35

1:35

HSESafetyInformation

17 days agoMutton Chops two ways- baked & grilled Recipe by Food Fusion (Eid Recipe)

49 -

1:00:54

1:00:54

The Tom Renz Show

6 hours agoMore Epstein/FBI, a Scary Trade War, & the Dem Echo Chamber

829 -

40:43

40:43

Kimberly Guilfoyle

7 hours agoDems Double Down on Delusion-Why? Live with Tony Kinnett & Bo French | Ep.202

61.7K30 -

1:28:42

1:28:42

Redacted News

5 hours agoBREAKING! SOMETHING BIG IS HAPPENING IN EUROPE ALL OUT WAR IS COMING AGAINST RUSSIA, TRUMP FURIOUS

108K259 -

47:50

47:50

Candace Show Podcast

5 hours agoBREAKING: Judge Makes Statement Regarding Taylor Swift's Text Messages. | Candace Ep 155

94.3K102 -

DVR

DVR

Josh Pate's College Football Show

2 hours agoCFB’s Most Hated Teams | FSU & Clemson Future | Big Ten Win Totals | Star Rankings Overrated?

5.76K -

1:33:47

1:33:47

CatfishedOnline

4 hours agoGoing Live With Robert - Weekly Recap

19.4K -

55:18

55:18

LFA TV

1 day agoEurope’s Sudden Turn Against America | TRUMPET DAILY 3.6.25 7PM

25.5K3 -

4:21

4:21

Tundra Tactical

3 hours ago $1.38 earnedPam Bondi MUST Enforce Due Process NOW!

18.4K1 -

56:42

56:42

VSiNLive

5 hours agoFollow the Money with Mitch Moss & Pauly Howard | Hour 1

43.6K1