Premium Only Content

Mechanical Power Press Safety Training

**Mechanical Power Press Safety Training** is essential for employees who operate, maintain, or supervise the use of power presses in manufacturing environments. These machines pose significant hazards if improperly used, so training ensures compliance with OSHA standards and minimizes workplace injuries.

### Key Components of Mechanical Power Press Safety Training

1. **Overview of Power Presses**:

- Understanding different types of presses, including hydraulic and mechanical.

- Common uses of power presses in manufacturing.

2. **Hazards of Mechanical Power Presses**:

- Point-of-operation hazards (where the machine performs its task, e.g., cutting or shaping material).

- Risks from moving parts, pinch points, and ejection of materials.

3. **OSHA Standards**:

- OSHA 29 CFR 1910.217: Specific safety regulations for mechanical power presses.

- OSHA requirements for regular inspection, testing, and safeguarding.

4. **Safe Operation Procedures**:

- Proper startup, shutdown, and operational protocols.

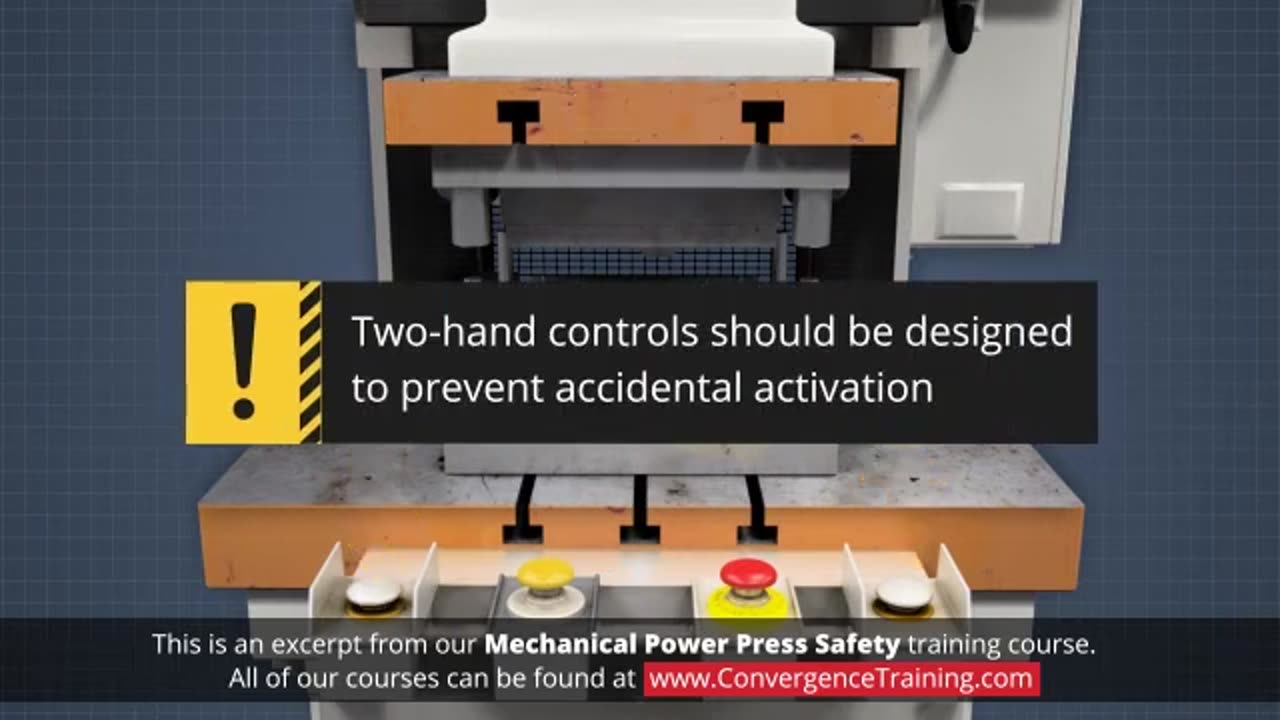

- Using safeguards such as two-hand controls, barrier guards, and light curtains.

5. **Maintenance and Inspection**:

- The importance of regular maintenance to prevent malfunction.

- How to perform inspections and identify wear, damage, or needed adjustments.

6. **Lockout/Tagout (LOTO)**:

- OSHA 29 CFR 1910.147: Procedures to de-energize equipment during maintenance.

- Steps to prevent accidental activation.

7. **Emergency Response**:

- Actions to take in the event of equipment failure or injury.

- First aid procedures and reporting protocols.

8. **Recordkeeping**:

- Documenting inspections, maintenance, and training to meet compliance requirements.

---

### Methods of Delivery

- **Instructor-Led Training**: Includes classroom sessions with hands-on demonstrations.

- **Online Courses**: Many providers, like OSHA and private training firms, offer online modules with certification.

- **On-the-Job Training**: Tailored training specific to the machines and workplace environment.

---

### Importance of Training

- Reduces injuries like amputations, crushing, or lacerations.

- Ensures compliance with OSHA standards, avoiding costly fines.

- Promotes a safer and more productive work environment.

Would you like recommendations for training providers or specific resources?

-

DVR

DVR

xBuRnTx

2 hours agoWho's Ready for New Years!

16.3K -

12:09

12:09

Tactical Advisor

14 hours agoSmith & Wesson Shield Plus Carry Comp

12K1 -

4:35:25

4:35:25

Father Russell

7 hours agoDelta Force | Not A Woman? | Mad Martigan Time

54.8K3 -

3:29:42

3:29:42

BrookieMonster

14 hours ago $44.15 earnedChristmas Stream: Marvel Rivals with CallmeSeags 🎄

175K13 -

LIVE

LIVE

TheSaf3Hav3n

4 days ago| RUMBLES FIRST SUBATHON IS HERE!!! | DAY 4 |

414 watching -

6:54

6:54

Dr. Nick Zyrowski

2 hours agoHIGH PROTEIN DIET Fixes Your Metabolism! - Weight Loss Not Required

14.6K5 -

3:14:33

3:14:33

Joe Donuts Gaming

16 hours ago🟢 Live : Christmas is Here!! | Fortnite, Caroling, Light Tours and Donos !!

92.5K15 -

6:02:38

6:02:38

CLUJ

15 hours agoCHRISTMAS EVENING HYPE!! LETS HAVE FUN GAMING!!

73.3K7 -

![I AM FINALLY BACK :: PUBG: BATTLEGROUNDS :: RUMBLE NOW HAS GIFTED SUBS!!! [Merry Christmas] {18+}](https://1a-1791.com/video/fwe1/22/s8/1/e/f/C/6/efC6v.0kob-small-I-AM-FINALLY-BACK-PUBG-BATT.jpg) 9:57:19

9:57:19

a12cat34dog

17 hours agoI AM FINALLY BACK :: PUBG: BATTLEGROUNDS :: RUMBLE NOW HAS GIFTED SUBS!!! [Merry Christmas] {18+}

65.5K8 -

3:55:42

3:55:42

STARM1X16

17 hours agoMerry Christmas Fortnite

135K11