Premium Only Content

Volatile Solvent Spill Response Training

**Volatile Solvent Spill Response Training** is crucial for ensuring employee safety and minimizing health, environmental, and fire hazards. Below is a structured outline to develop an effective training program.

---

### **Training Objectives**

1. Understand the risks and hazards associated with volatile solvents.

2. Learn the proper steps to respond to spills safely and efficiently.

3. Ensure compliance with workplace safety standards and regulations.

4. Familiarize employees with the required tools, PPE, and emergency response equipment.

---

### **Core Topics to Include**

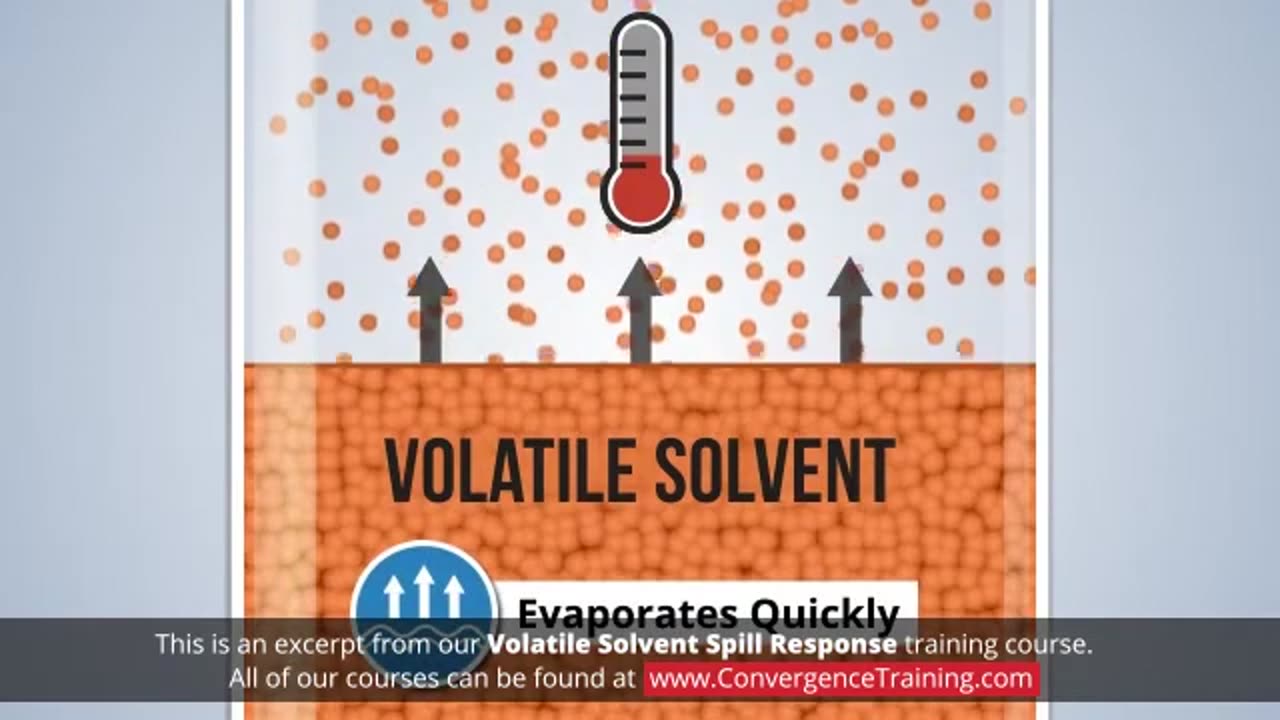

#### **1. Understanding Volatile Solvents**

- **What are volatile solvents?**

- Organic compounds that easily evaporate at room temperature, often posing health, fire, and explosion risks.

- Common examples: Acetone, toluene, ethanol, methanol, benzene, and xylene.

- **Hazards**:

- **Health risks**:

- Inhalation: Dizziness, headaches, respiratory distress, or long-term organ damage.

- Skin contact: Irritation or chemical burns.

- Ingestion: Severe toxicity.

- **Fire and explosion risks**:

- High flammability and low flash points.

- Vapors may travel and ignite at distant ignition sources.

- **Environmental risks**:

- Solvent contamination of water and soil.

- **Regulatory requirements**:

- OSHA Hazard Communication Standard.

- EPA guidelines for hazardous waste management.

- NFPA (National Fire Protection Association) classifications for flammable liquids.

---

#### **2. Spill Prevention**

- **Storage best practices**:

- Store solvents in tightly sealed, compatible containers.

- Keep containers in ventilated, fire-resistant storage areas.

- Avoid storing near ignition sources (e.g., flames, hot surfaces, or static electricity).

- **Work area organization**:

- Minimize the amount of solvent stored in workspaces.

- Use secondary containment (e.g., spill trays).

- **Regular inspections**:

- Check for leaks, corroded containers, or improperly labeled solvents.

---

#### **3. Spill Response Basics**

- **Initial response actions**:

- Alert nearby personnel about the spill.

- Evacuate the area if the spill is large or involves toxic vapors.

- Shut off ignition sources and equipment that could spark.

- Restrict access to the spill site to prevent exposure.

- **Size assessment**:

- **Small spills**: Containable with available spill kits and manageable without external help.

- **Large spills**: Require evacuation, emergency services, or HazMat team intervention.

---

#### **4. Spill Cleanup Procedures**

- **Personal Protective Equipment (PPE)**:

- Always wear appropriate PPE before addressing spills:

- Chemical-resistant gloves (e.g., nitrile or butyl rubber).

- Safety goggles or face shields.

- Respiratory protection (e.g., organic vapor cartridges or supplied air respirators for large spills).

- Flame-resistant (FR) clothing if working with flammable solvents.

- **Ventilation**:

- Open windows, doors, or turn on fume hoods to disperse vapor buildup safely.

- **Containment**:

- Use absorbent materials (e.g., spill pads, vermiculite, or activated carbon) to prevent the spill from spreading.

- For large spills, create a containment barrier (e.g., spill berms or sandbags).

- **Neutralization and cleanup**:

- Absorb the spill using materials compatible with the solvent.

- Do not use water unless the solvent is water-soluble and recommended by the Safety Data Sheet (SDS).

- Avoid vacuuming flammable solvent spills unless using intrinsically safe equipment.

- **Disposal**:

- Collect cleanup materials in sealed, compatible containers.

- Label waste containers and dispose of them per hazardous waste regulations.

---

#### **5. Emergency Response**

- **Fire risks**:

- If a spill ignites, use appropriate fire extinguishers:

- **Class B extinguishers**: Foam, CO₂, or dry chemical.

- Avoid using water on solvent fires unless specifically advised.

- **Exposure response**:

- **Skin contact**: Rinse thoroughly with soap and water.

- **Eye contact**: Flush with water for 15-20 minutes and seek medical attention.

- **Inhalation**: Move to fresh air immediately; provide oxygen if breathing is difficult.

- **Ingestion**: Do not induce vomiting unless directed by medical personnel.

- **Emergency communication**:

- Know the location of emergency contact numbers, including Poison Control, HazMat teams, and fire departments.

- Notify supervisors and the Environmental Health and Safety (EHS) team.

---

#### **6. Regulatory Compliance and Documentation**

- **Safety Data Sheets (SDS)**:

- Review SDS for each volatile solvent to understand specific spill response guidelines.

- **Spill reporting**:

- Document all spills, including time, location, quantity, and response measures.

- Report large spills to environmental agencies as required (e.g., EPA in the U.S.).

- **Training requirements**:

- OSHA mandates annual training for employees working with hazardous chemicals.

- Tailor training to the specific solvents used in your facility.

---

#### **7. Spill Kits and Emergency Equipment**

- **Spill kit components**:

- Absorbent pads, booms, or pillows.

- Non-sparking tools (e.g., scoops, scrapers).

- Chemical-resistant gloves and aprons.

- Sealed waste bags and labels.

- Emergency response guide.

- **Fire safety equipment**:

- Class B fire extinguishers.

- Grounding and bonding equipment for handling flammable solvents.

- **Eyewash stations and safety showers**:

- Ensure they are accessible and tested regularly.

---

### **Training Delivery Methods**

1. **Classroom Instruction**:

- Explain the theory behind volatile solvent hazards and spill response procedures.

2. **Hands-On Demonstrations**:

- Show how to use spill kits effectively.

- Demonstrate containment techniques for small spills.

3. **Simulation Drills**:

- Conduct mock spill scenarios to practice response procedures.

4. **Quizzes and Assessments**:

- Test knowledge of hazards, PPE, and spill cleanup steps.

5. **On-the-Job Training**:

- Supervisors observe employees handling solvents and responding to simulated spills.

---

### **Follow-Up and Evaluation**

- **Inspection and maintenance**:

- Regularly inspect spill kits and PPE for availability and condition.

- Update SDS and emergency response procedures when new solvents are introduced.

- **Refresher training**:

- Conduct annual spill response refresher courses.

- Review incidents or near misses to improve procedures.

- **Employee feedback**:

- Encourage employees to share challenges or improvements for spill response protocols.

---

Would you like help preparing **customized training materials, detailed spill response flowcharts, or scenario-based drills**?

-

3:29:42

3:29:42

BrookieMonster

14 hours ago $43.52 earnedChristmas Stream: Marvel Rivals with CallmeSeags 🎄

164K13 -

LIVE

LIVE

TheSaf3Hav3n

3 days ago| RUMBLES FIRST SUBATHON IS HERE!!! | DAY 4 |

480 watching -

6:54

6:54

Dr. Nick Zyrowski

1 hour agoHIGH PROTEIN DIET Fixes Your Metabolism! - Weight Loss Not Required

8.01K5 -

3:14:33

3:14:33

Joe Donuts Gaming

16 hours ago🟢 Live : Christmas is Here!! | Fortnite, Caroling, Light Tours and Donos !!

87.2K15 -

6:02:38

6:02:38

CLUJ

15 hours agoCHRISTMAS EVENING HYPE!! LETS HAVE FUN GAMING!!

69.3K7 -

![I AM FINALLY BACK :: PUBG: BATTLEGROUNDS :: RUMBLE NOW HAS GIFTED SUBS!!! [Merry Christmas] {18+}](https://1a-1791.com/video/fwe1/22/s8/1/e/f/C/6/efC6v.0kob-small-I-AM-FINALLY-BACK-PUBG-BATT.jpg) 9:57:19

9:57:19

a12cat34dog

17 hours agoI AM FINALLY BACK :: PUBG: BATTLEGROUNDS :: RUMBLE NOW HAS GIFTED SUBS!!! [Merry Christmas] {18+}

61.7K8 -

3:55:42

3:55:42

STARM1X16

16 hours agoMerry Christmas Fortnite

132K11 -

2:45:33

2:45:33

Sgtfinesse

16 hours agoMerry Christmas Night

95.3K19 -

3:51:18

3:51:18

tacetmort3m

1 day ago🔴 LIVE - (MERRY CHRISTMAS) TIME TO SPREAD DEMOCRACY - HELLDIVERS 2 OMENS OF TYRANNY

58.2K2 -

2:46

2:46

BIG NEM

20 hours agoDiscovering RAKIJA: The Holy Liquer of the Balkans

42.9K3