Premium Only Content

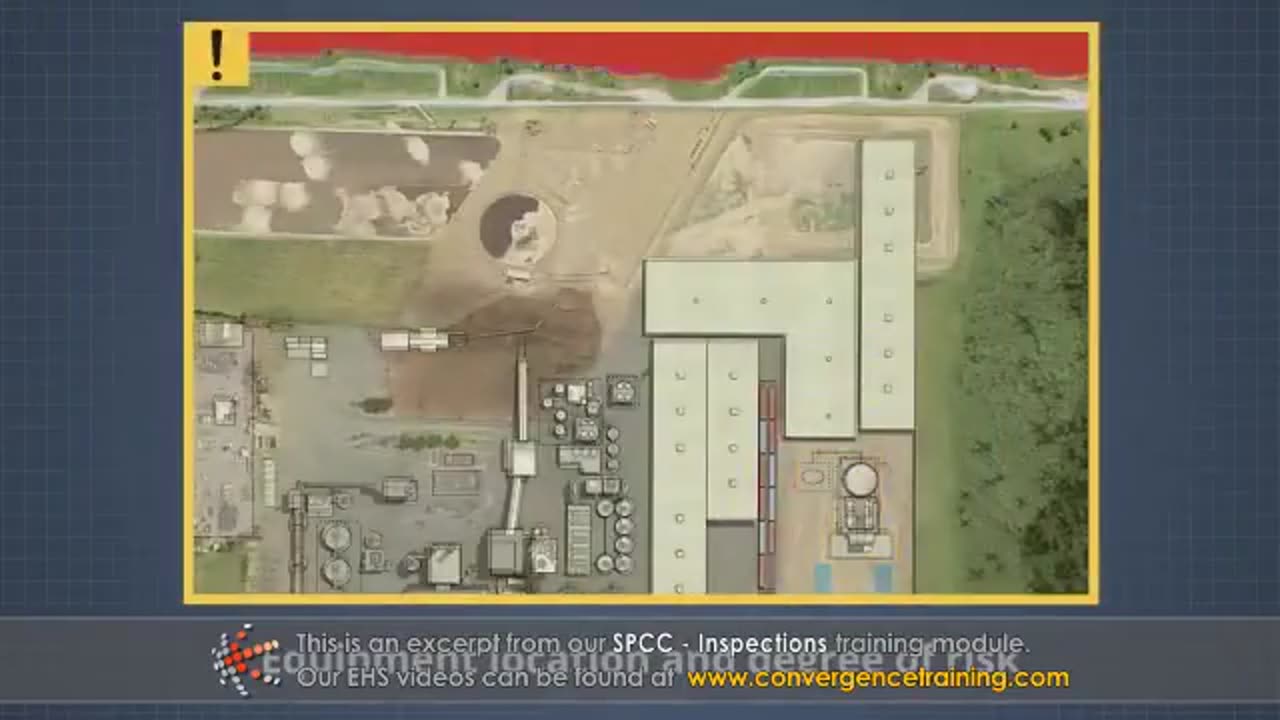

SPCC Inspections Training

SPCC (Spill Prevention, Control, and Countermeasure) inspections training focuses on ensuring compliance with the EPA's SPCC Rule, aimed at preventing oil discharges into navigable waters or adjoining shorelines. Below is a detailed outline for SPCC inspections training:

---

### **1. Overview of SPCC Regulations**

- **Purpose of SPCC Rule:** Prevent oil spills and mitigate environmental damage.

- **Applicability:** Facilities with oil storage capacity >1,320 gallons (aboveground) or >42,000 gallons (underground).

- **Key Elements:** Spill prevention, control measures, and countermeasures.

---

### **2. Roles and Responsibilities**

- **Facility Owner/Operator:** Responsible for compliance and implementing the SPCC Plan.

- **Inspection Personnel:** Conduct regular inspections, identify potential risks, and ensure corrective actions are implemented.

- **Certified Engineer (if applicable):** Approves and certifies SPCC Plan.

---

### **3. SPCC Plan Requirements**

- **Plan Content:**

- Description of the facility and potential spill risks.

- Oil storage locations, secondary containment systems, and drainage paths.

- Inspection and maintenance schedules.

- Spill response procedures and contact information.

- **Accessibility:** The SPCC Plan must be available onsite and reviewed every 5 years.

---

### **4. Inspection Procedures**

#### **Daily/Regular Inspections**

- **Tanks:** Check for cracks, corrosion, or leaks.

- **Secondary Containment:** Ensure it’s free of oil and debris and can contain spills.

- **Valves and Pipes:** Inspect for signs of wear, leaks, or damage.

#### **Periodic Integrity Testing**

- **Aboveground Storage Tanks (ASTs):** Conduct hydrostatic, ultrasonic, or visual testing as required.

- **Pipelines:** Verify structural integrity and pressure testing.

#### **Documentation**

- Record inspection dates, findings, and corrective actions.

- Maintain logs for a minimum of 3 years.

---

### **5. Spill Control Measures**

- **Secondary Containment:** Use dikes, berms, or retention basins.

- **Spill Kits:** Ensure proper placement and accessibility of spill containment tools (e.g., absorbents, booms).

- **Drip Pans:** Under valves or fittings during operations.

---

### **6. Emergency Response Training**

- **Spill Reporting:** Train staff on when and how to report spills to internal teams and regulatory agencies.

- **Response Actions:**

- Contain the spill using spill kits.

- Notify the appropriate personnel and agencies.

- Implement cleanup measures according to the SPCC Plan.

---

### **7. Compliance and Auditing**

- Conduct annual facility audits to assess compliance with SPCC regulations.

- Review and update the SPCC Plan to reflect operational changes, new risks, or regulatory updates.

---

### **8. Practice Scenarios**

- Role-play emergency response scenarios to test the team's preparedness.

- Conduct mock inspections to familiarize personnel with the process.

---

Would you like this as a detailed document or checklist? I can also include sample inspection forms or tables for tracking.

-

LIVE

LIVE

Candace Show Podcast

1 hour agoI Respond To Mr. And Mr. Macron | Candace Ep 131

8,593 watching -

LIVE

LIVE

Revenge of the Cis

2 hours agoEpisode 1429: Catch And Release

1,970 watching -

LIVE

LIVE

Film Threat

7 hours agoVERSUS: HOLLYWOOD IS STILL ON FIRE | Film Threat Versus

145 watching -

12:33

12:33

Silver Dragons

1 hour agoSilver Price Crushed Today - NEW TREND STARTING?

2.27K -

1:02:03

1:02:03

In The Litter Box w/ Jewels & Catturd

20 hours agoRecall Newscum & Bass! | In the Litter Box w/ Jewels & Catturd – Ep. 718 – 1/13/2025

38.7K15 -

3:19:58

3:19:58

Tate Speech by Andrew Tate

8 hours agoEMERGENCY MEETING EPISODE 101 - STRENGTH AND HONOR

129K52 -

1:48:09

1:48:09

The Quartering

4 hours agoLA Fires Are About To Get Way Worse, Trump Vs Vance On J6 Pardons, Brett Cooper Bombshell & More

66.2K29 -

LIVE

LIVE

Dr Disrespect

5 hours ago🔴LIVE - DR DISRESPECT - MARVEL RIVALS - TOP 500 IN THE WORLD

3,398 watching -

1:05:49

1:05:49

MTNTOUGH Fitness Lab

6 hours agoDamon West: How Faith and Mental Toughness Helped Me Escape Prison | MTNPOD #99

6.49K -

1:43:05

1:43:05

The Criminal Connection Podcast

7 hours agoIAN MCCRANOR: World Champion Karate Doorman CRAZY Life Story, Mob Hits GONE WRONG & Video Game Star!

5.58K1