Premium Only Content

Line Breaking Safety Training

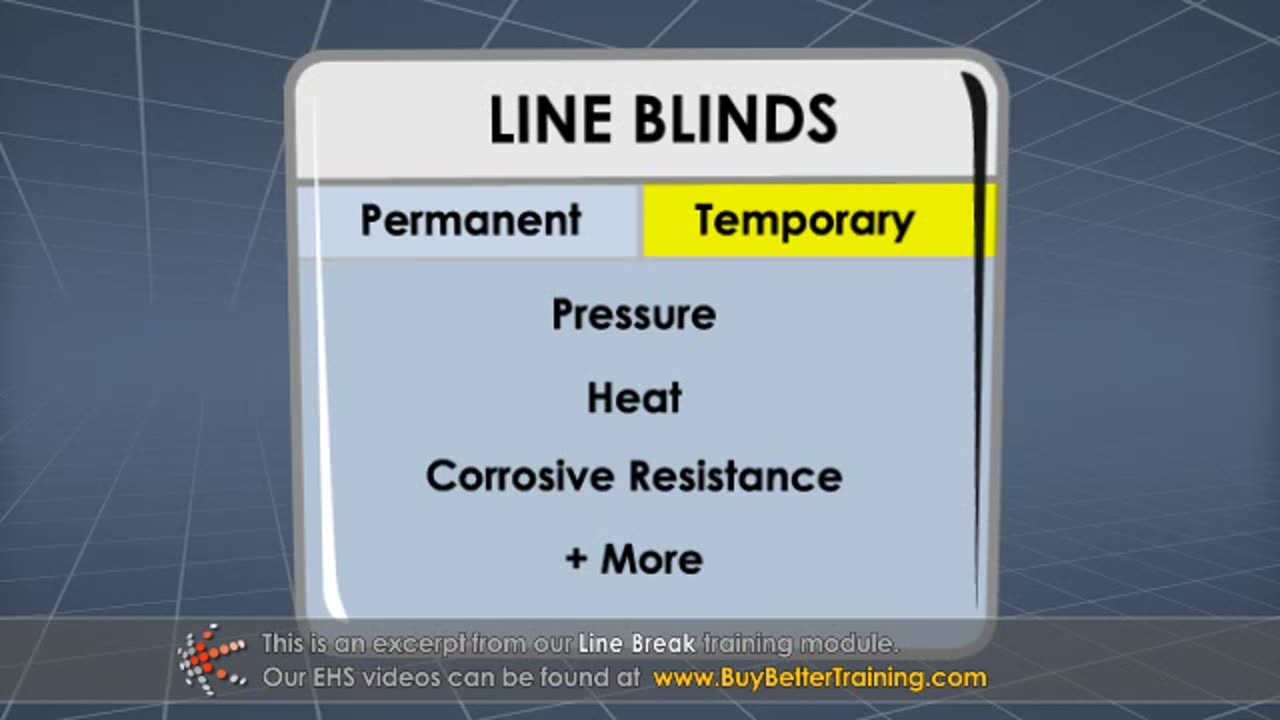

**Line Breaking Safety Training** is crucial for workers involved in maintenance, repair, or servicing of pipelines, pressure vessels, tanks, and other confined systems where the removal or disconnection of components (such as valves or flanges) can result in the release of hazardous substances. Line breaking refers to the process of opening a line (such as a pipe or valve) and is often associated with the risk of exposure to dangerous chemicals, gases, or other hazardous materials.

This training is designed to equip workers with the knowledge and procedures necessary to safely perform line breaks, reducing the risk of injury, exposure to hazardous substances, and damage to equipment.

### **Key Elements of Line Breaking Safety Training**

#### 1. **Understanding the Hazards**

- **Chemical Exposure**: Many pipelines carry hazardous materials (e.g., chemicals, natural gas, flammable liquids) that can be dangerous if released during line breaking.

- **Pressure Hazards**: Pressurized lines can cause sudden and uncontrolled releases of fluids, gases, or vapors, leading to accidents, burns, and explosions.

- **Toxicity and Asphyxiation**: Some substances in pipelines may be toxic, corrosive, or asphyxiating, posing health risks to workers if inhaled or touched.

- **Mechanical Hazards**: The process of breaking a line could lead to equipment failures, creating risk from leaks or sudden movements of machinery.

- **Fires and Explosions**: Flammable materials, when exposed to ignition sources, can cause fires or explosions, especially if the system is not properly de-pressurized before the break.

#### 2. **Preparation Before Line Breaking**

- **Permit-to-Work System**: Ensure that line breaking is authorized through a formal permit-to-work system. This system requires that specific safety protocols are met before work begins.

- **Isolate the Line**: Before breaking any line, ensure that the line is fully isolated from the system. This includes:

- Shutting off valves and pumps.

- Bleeding off pressure (if applicable).

- Draining any fluids or gases from the system.

- **Lockout/Tagout (LOTO)**: Lockout and tagout procedures should be followed to ensure that the line cannot be accidentally re-energized or pressurized during the work.

- **Ventilate the Area**: If there are potentially hazardous gases or vapors in the line, ensure the work area is properly ventilated. In confined spaces, forced ventilation or the use of air-purifying respirators may be required.

#### 3. **Personal Protective Equipment (PPE)**

- **Respiratory Protection**: Use the appropriate type of respiratory protection, such as air-supplied respirators or gas masks, depending on the risks present (e.g., toxic gases or insufficient oxygen).

- **Eye and Face Protection**: Wear goggles or face shields to protect against chemical splashes, flying debris, or high-pressure releases.

- **Protective Clothing**: Depending on the materials being handled, wear chemical-resistant suits, gloves, and boots.

- **Hearing Protection**: In noisy environments, hearing protection may be needed due to loud equipment or pressure releases.

- **Flame-Resistant Clothing**: If working with flammable or explosive materials, flame-resistant clothing should be worn.

#### 4. **Steps for Safe Line Breaking**

- **Confirm System Is Isolated**: Verify that the pipeline is isolated from any source of pressure, and that all valves are closed. Confirm that no hazardous materials are left in the line.

- **Check for Leaks**: Before breaking the line, inspect the entire system for any leaks that could lead to a hazardous release during the break.

- **De-pressurize the Line**: Ensure that the line is de-pressurized to prevent sudden releases of materials or gases. Use venting, draining, or purging methods as necessary to achieve this.

- **Monitor for Hazardous Atmospheres**: In confined spaces, monitor the atmosphere using gas detectors for potential hazards, such as oxygen deficiency, flammable gases, or toxic fumes.

- **Purge Lines**: If necessary, purge the line with an inert gas (such as nitrogen) to displace any hazardous materials before breaking the line.

- **Break the Line Slowly**: Once the system is fully isolated and the line is de-pressurized, break the line slowly and carefully to avoid creating dangerous conditions.

#### 5. **Handling Emergencies**

- **Prepare for Spills and Leaks**: Have spill kits and containment materials readily available in case of accidental leaks or spills.

- **Fire Safety**: Ensure that fire extinguishers or fire suppression systems are nearby, especially when working with flammable or explosive substances.

- **First Aid**: Train workers in basic first aid, specifically for chemical burns, respiratory distress, or trauma from high-pressure releases. Ensure that emergency medical services can be quickly reached.

- **Evacuation Plan**: Develop and communicate an evacuation plan in case of a hazardous release or fire. Workers should be aware of the nearest exits and safe areas.

#### 6. **Post-Line-Breaking Procedures**

- **Check for Leaks After Reconnection**: After the line is reconnected or the work is completed, check for any signs of leaks or pressure anomalies before resuming normal operations.

- **Return to Service**: Ensure that the line is properly purged of any hazardous materials, and all safety checks are performed before returning the system to service.

- **Document and Report**: Record the results of the line-breaking process, including safety checks, isolation procedures, and any incidents that occurred during the process. This documentation helps in future safety planning.

### **7. Key Training Components**

- **Training on the Permit-to-Work System**: Workers must understand the importance of obtaining and following proper permits before performing line-breaking activities.

- **Awareness of Chemical Hazards**: Ensure that workers understand the specific hazards associated with the chemicals or materials being transported through the pipeline.

- **Understanding PPE Requirements**: Provide training on selecting and using the correct personal protective equipment based on the hazards present.

- **Hands-on Practice**: Conduct hands-on training, where workers can practice the procedures for isolating, de-pressurizing, and safely breaking lines under controlled conditions.

- **Emergency Response Drills**: Simulate emergency scenarios to practice responding to line-break accidents, including evacuations, containment, and medical emergencies.

### **8. Conclusion**

Line breaking safety training ensures that workers understand the risks involved with breaking open pipelines, tanks, and systems and are equipped with the knowledge and tools to perform these tasks safely. Proper isolation, de-pressurization, ventilation, and personal protective equipment are key to preventing accidents and ensuring that the line-breaking process is conducted safely and effectively.

-

12:33

12:33

Silver Dragons

2 hours agoSilver Price Crushed Today - NEW TREND STARTING?

2.27K -

1:02:03

1:02:03

In The Litter Box w/ Jewels & Catturd

20 hours agoRecall Newscum & Bass! | In the Litter Box w/ Jewels & Catturd – Ep. 718 – 1/13/2025

38.7K16 -

3:19:58

3:19:58

Tate Speech by Andrew Tate

8 hours agoEMERGENCY MEETING EPISODE 101 - STRENGTH AND HONOR

129K56 -

1:48:09

1:48:09

The Quartering

5 hours agoLA Fires Are About To Get Way Worse, Trump Vs Vance On J6 Pardons, Brett Cooper Bombshell & More

83.1K35 -

LIVE

LIVE

Dr Disrespect

5 hours ago🔴LIVE - DR DISRESPECT - MARVEL RIVALS - TOP 500 IN THE WORLD

3,203 watching -

1:05:49

1:05:49

MTNTOUGH Fitness Lab

7 hours agoDamon West: How Faith and Mental Toughness Helped Me Escape Prison | MTNPOD #99

6.49K -

1:43:05

1:43:05

The Criminal Connection Podcast

7 hours agoIAN MCCRANOR: World Champion Karate Doorman CRAZY Life Story, Mob Hits GONE WRONG & Video Game Star!

5.58K1 -

38:25

38:25

otisframpton

2 hours agoPROCREATE DREAMS Animation Demo - Part 4 - Lighting & SFX!

16.3K -

1:53:53

1:53:53

vivafrei

4 hours agoGavin Newsom's War With Elon! Stolen Humvees FOUND? Arson Suspect IDENTIFIED? Cali Updates & MORE!

72.1K42 -

1:58:10

1:58:10

Nerdrotic

5 hours ago $4.06 earnedReconstructing the Superhero | FNT Square Up - Nerdrotic Nooner 457

59.1K6