Premium Only Content

Process Safety Management Training

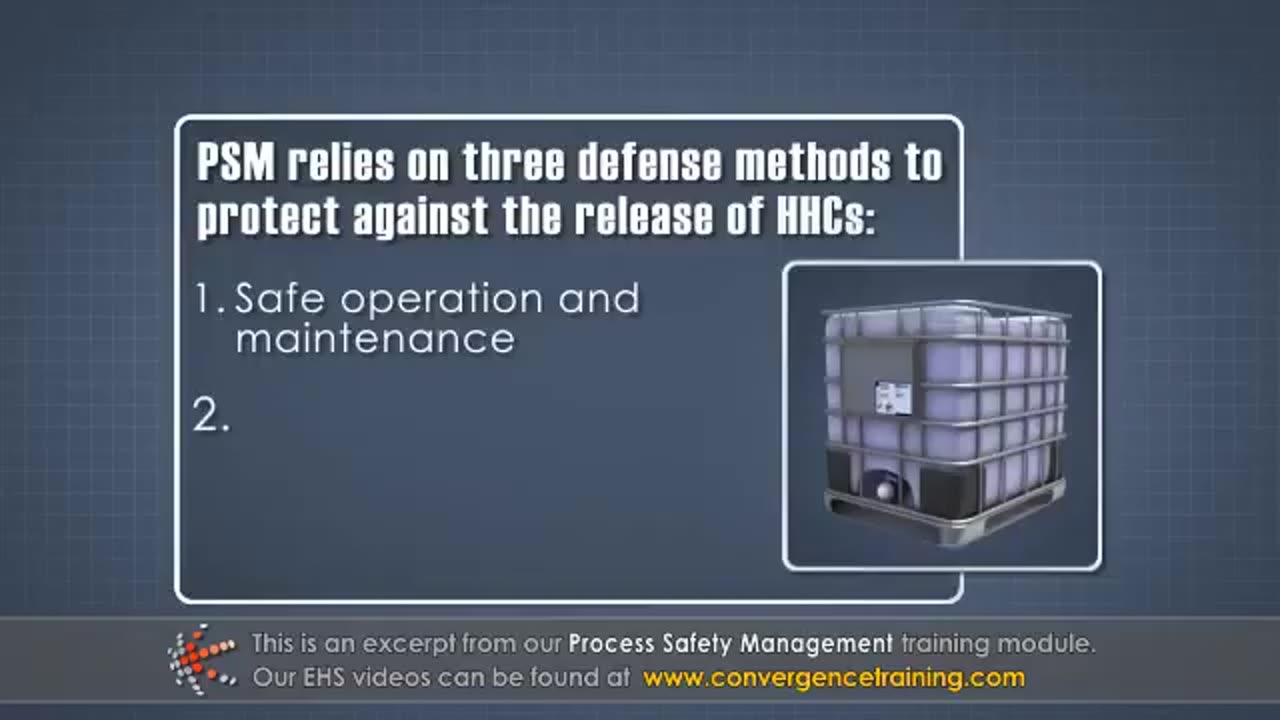

**Process Safety Management (PSM) Training** is designed to ensure workers understand the principles of preventing releases of hazardous chemicals and maintaining safe operations in processes involving highly hazardous substances. This training aligns with OSHA’s **Process Safety Management Standard (29 CFR 1910.119)** and is critical for industries such as chemical manufacturing, oil and gas, and pharmaceuticals.

---

### **Process Safety Management (PSM) Training Outline**

#### **1. Introduction to Process Safety Management**

- **What is PSM?**

- A systematic approach to managing processes involving highly hazardous chemicals.

- Focused on preventing catastrophic releases and incidents.

- **Why is PSM important?**

- Protects employees, communities, and the environment.

- Ensures compliance with OSHA regulations and industry best practices.

- Overview of OSHA’s **14 Elements of PSM**.

---

#### **2. Overview of Highly Hazardous Chemicals (HHCs)**

- Definition of HHCs:

- Chemicals with high potential for causing significant harm if released.

- Examples of HHCs:

- Flammable gases, toxic substances, and reactive chemicals.

- Recognizing hazardous processes in the workplace.

---

#### **3. Key Elements of the OSHA PSM Standard**

1. **Process Safety Information (PSI):**

- Collecting and maintaining data on hazardous chemicals, process technology, and equipment.

2. **Process Hazard Analysis (PHA):**

- Identifying and evaluating risks through tools like HAZOP or What-If analysis.

- Frequency and team composition for PHA reviews.

3. **Operating Procedures:**

- Developing and maintaining written instructions for safe operation.

- Including emergency shutdown procedures.

4. **Training:**

- Ensuring employees understand their roles in process safety.

- Periodic refresher training requirements.

5. **Mechanical Integrity:**

- Regular inspection, testing, and maintenance of critical equipment.

- Preventing equipment failures that could lead to hazardous releases.

6. **Management of Change (MOC):**

- Controlling risks associated with modifications to processes, equipment, or procedures.

7. **Incident Investigation:**

- Analyzing incidents and near-misses to identify root causes and implement corrective actions.

8. **Emergency Planning and Response:**

- Preparing for and responding effectively to chemical releases or other emergencies.

9. **Compliance Audits:**

- Regularly evaluating PSM program effectiveness and addressing deficiencies.

(Include the remaining OSHA PSM elements, depending on the audience's needs.)

---

#### **4. Hazard Identification and Risk Assessment**

- Identifying potential hazards in processes:

- Chemical reactivity, overpressurization, or equipment failures.

- Assessing and mitigating risks:

- Using tools like Bow-Tie Diagrams or Layer of Protection Analysis (LOPA).

- Importance of safety-critical systems and safeguards.

---

#### **5. Safe Work Practices**

- Examples of safe work practices:

- Lockout/Tagout (LOTO).

- Permit-to-Work (PTW) systems.

- Hot work permits and precautions.

- Ensuring consistency between work practices and operating procedures.

---

#### **6. Emergency Response Preparedness**

- Preparing for emergencies involving hazardous chemicals:

- Developing and practicing emergency action plans.

- Understanding the role of Emergency Response Teams (ERTs).

- Communicating with local emergency responders and community stakeholders.

---

#### **7. Roles and Responsibilities**

- **Employer responsibilities:**

- Implementing and maintaining an effective PSM program.

- Providing resources, training, and tools to manage process safety.

- **Employee responsibilities:**

- Adhering to operating procedures and reporting safety concerns.

- Actively participating in training and safety programs.

---

#### **8. Real-Life Case Studies**

- **Case study examples:**

- The Bhopal disaster (1984) – lessons in chemical safety.

- Texas City Refinery explosion (2005) – importance of mechanical integrity.

- Deepwater Horizon spill (2010) – role of management systems in prevention.

- Discussion of key takeaways and actionable lessons.

---

#### **9. Practical Exercises and Scenarios**

- Conducting a mock Process Hazard Analysis (PHA).

- Role-playing Management of Change (MOC) scenarios.

- Simulating emergency response to a chemical release incident.

---

#### **10. Quiz and Certification**

- Administer a knowledge assessment to test understanding.

- Provide certificates for participants who successfully complete the training.

---

Would you like this training tailored for specific processes or industries? I can also assist in developing presentations, quizzes, or detailed materials for the course.

-

1:35

1:35

HSESafetyInformation

1 month agoMutton Chops two ways- baked & grilled Recipe by Food Fusion (Eid Recipe)

53 -

41:03

41:03

Kimberly Guilfoyle

7 hours agoTrump approval up, Dems melting down. Live with Asm Bill Essayli & Jarrett Stepman | Ep206

91.1K19 -

59:20

59:20

Candace Show Podcast

5 hours agoSo… The “Conspiracy Theorists” Were Right About JFK | Candace Ep 164

122K193 -

1:10:15

1:10:15

Sarah Westall

3 hours agoIs Trump bringing the US through a Bankruptcy Reorganization? Planning for Reset w/ Andy Schectman

25.8K3 -

LIVE

LIVE

Mally_Mouse

2 hours agoLet's Play!! - R.E.P.O. - w/ friends

94 watching -

54:49

54:49

LFA TV

1 day agoCan Donald Trump Bring Peace? | TRUMPET DAILY 3.20.25 7PM

23.5K1 -

1:34:34

1:34:34

vivafrei

10 hours agoLive with Gad Saad! Tesla on Fire! Canada on TDS! And "Suicidal Empathy" Turns Violent? Viva Frei

141K62 -

1:12:11

1:12:11

The Officer Tatum

5 hours agoLIVE: JFK Files Update, Wesley Hunt vs. D.L. Hughley, YouTube Challenge GOES WRONG & More | EP 82

58.1K37 -

1:36:03

1:36:03

Tucker Carlson

1 day agoBob Lighthizer: Why Trump's Tariffs are the Only Way to Save the Middle Class

156K145 -

1:01:23

1:01:23

In The Litter Box w/ Jewels & Catturd

1 day agoTESLA TERRORISM | In the Litter Box w/ Jewels & Catturd – Ep. 766 – 3/20/2025

94.8K20