Premium Only Content

Chemical Unloading Basics Training

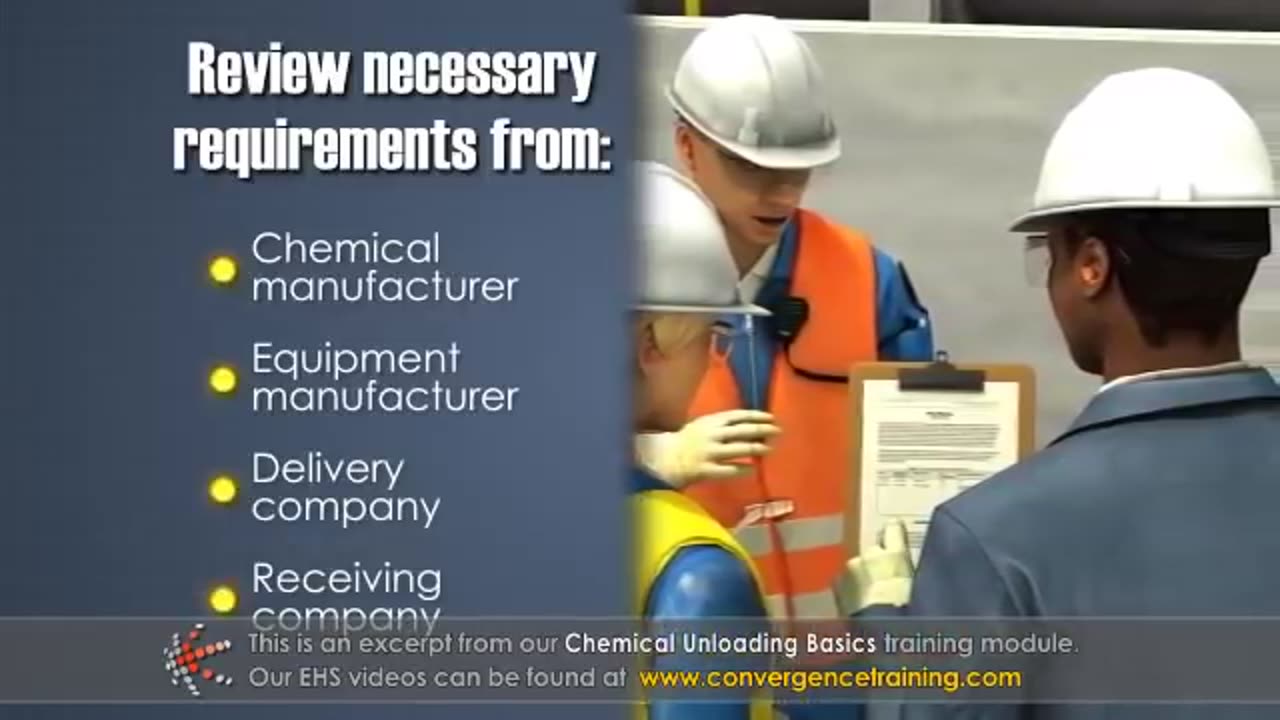

**Chemical Unloading Basics Training** is essential for employees who handle the unloading of hazardous chemicals to ensure safety, prevent accidents, and comply with regulatory standards. Here's an outline of the critical elements typically covered in this training program:

---

### **1. Objectives of the Training**

- To understand the risks associated with chemical unloading.

- To learn proper unloading procedures.

- To recognize and use safety equipment effectively.

- To identify and respond to potential hazards and emergencies.

---

### **2. Who Needs This Training?**

- Warehouse and plant operators.

- Tanker and bulk chemical truck drivers.

- Supervisors overseeing chemical handling processes.

- Maintenance staff working near unloading areas.

---

### **3. Understanding Chemicals and Their Risks**

- **Types of Chemicals Unloaded:**

- Acids, bases, solvents, gases, and other industrial chemicals.

- **Hazards Associated With Chemicals:**

- Flammability, reactivity, corrosivity, and toxicity.

- **Reading Safety Data Sheets (SDS):**

- Information on chemical properties, risks, and handling precautions.

---

### **4. Personal Protective Equipment (PPE)**

- Common PPE used during chemical unloading:

- Chemical-resistant gloves and suits.

- Goggles and face shields.

- Respiratory protection, if necessary.

- Inspection and proper use of PPE to ensure effectiveness.

---

### **5. Equipment and Tools for Chemical Unloading**

- Types of unloading systems:

- Hoses, pumps, valves, and connections.

- Inspection and maintenance of unloading equipment.

- Proper use of grounding and bonding to prevent static discharge.

---

### **6. Step-by-Step Unloading Procedures**

- **Preparation:**

- Verifying permits, documentation, and pre-unloading inspections.

- **Unloading:**

- Connecting equipment securely.

- Monitoring pressure, flow rates, and chemical levels.

- **Post-Unloading:**

- Disconnecting equipment safely.

- Cleaning and securing the unloading area.

---

### **7. Emergency Preparedness and Response**

- Identifying spills, leaks, or other incidents.

- Using spill kits and containment measures.

- Evacuation procedures and emergency shutdown processes.

- Reporting incidents to supervisors and regulatory agencies.

---

### **8. Regulatory Compliance**

- Overview of applicable regulations, such as:

- OSHA's Hazard Communication Standard.

- EPA regulations (e.g., Spill Prevention, Control, and Countermeasure [SPCC]).

- Local or industry-specific requirements.

- Documentation and record-keeping for unloading operations.

---

### **9. Best Practices for Chemical Unloading**

- Maintaining clear communication with all team members.

- Keeping the unloading area clean and organized.

- Regular training updates and drills to reinforce safety practices.

---

### **10. Duration and Certification**

- Training typically lasts 2–6 hours, depending on the depth and complexity of the materials.

- Certification is often provided upon completion, with periodic refresher courses required.

Would you like detailed guidance on a specific unloading process or related safety measures?

-

1:04:52

1:04:52

Geeks + Gamers

2 hours agoDisney RATIO'D on Christmas Day | Mufasa Embarrassed By Sonic 3

13.8K1 -

LIVE

LIVE

Sm0k3m

6 hours agoPlaying games on Rumble

251 watching -

10:37

10:37

Russell Brand

2 days agoHow is this even allowed?

113K693 -

1:37:26

1:37:26

Real Coffee With Scott Adams

3 hours agoEpisode 2701 CWSA 12/26/24

40.2K39 -

2:58:58

2:58:58

Wendy Bell Radio

8 hours ago9 Steps Ahead

80K109 -

LFA TV

16 hours agoTIME FOR A NEW SPEAKER! | LIVE FROM AMERICA 12.26.24 11am EST

31.5K28 -

1:40:22

1:40:22

Game On!

13 hours ago $4.43 earnedNFL Thursday Night Football Seahawks at Bears EXPERT Picks!

33.3K9 -

1:50:54

1:50:54

xBuRnTx

3 hours agoWho's Ready for New Years!

23.5K1 -

12:09

12:09

Tactical Advisor

15 hours agoSmith & Wesson Shield Plus Carry Comp

19.3K1 -

4:35:25

4:35:25

Father Russell

8 hours agoDelta Force | Not A Woman? | Mad Martigan Time

60.9K5