Premium Only Content

Anhydrous Ammonia Awareness Training

### **Anhydrous Ammonia Awareness Training Outline**

This training is designed to educate workers on the properties, hazards, and safe handling of anhydrous ammonia, a commonly used chemical in agriculture and industrial settings. The goal is to promote awareness and preparedness to prevent accidents and injuries.

---

### **1. Introduction to Anhydrous Ammonia**

- **What is anhydrous ammonia?**

- A colorless, highly irritating gas with a pungent odor.

- Widely used as a fertilizer and industrial refrigerant.

- **Purpose of training:**

- Understand the hazards associated with anhydrous ammonia.

- Learn safe handling procedures and emergency responses.

---

### **2. Physical and Chemical Properties**

- **Characteristics:**

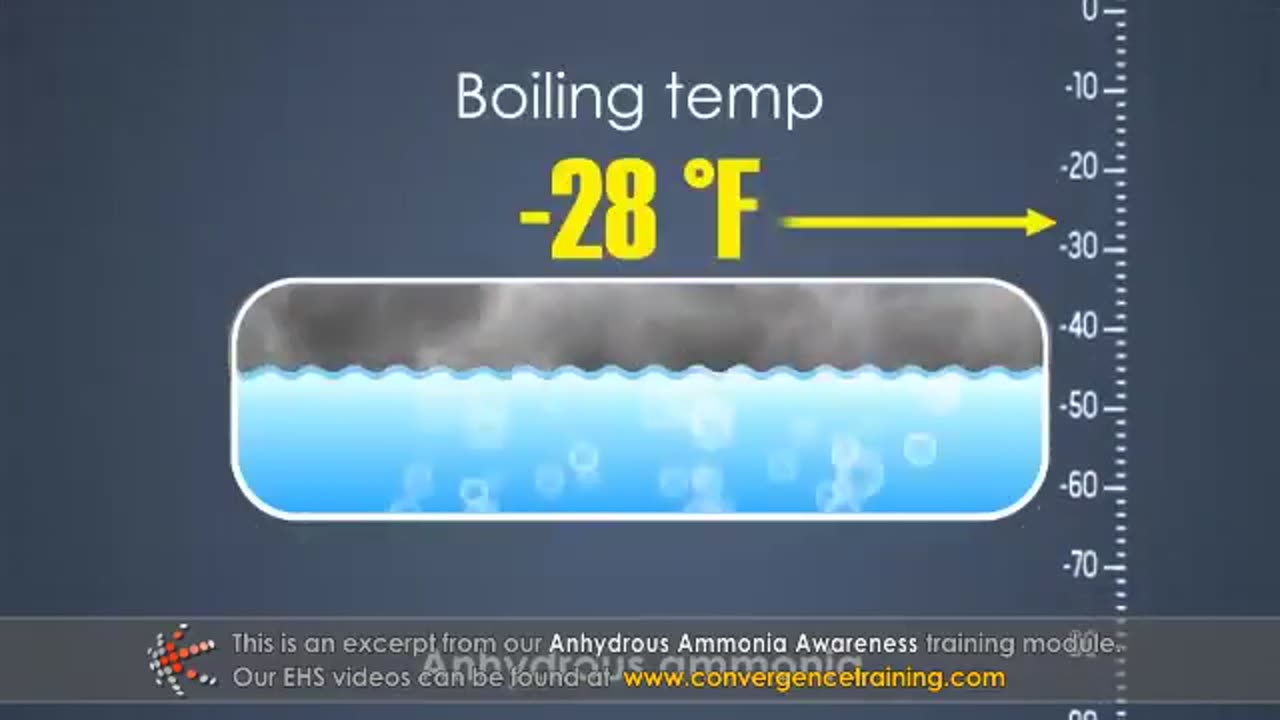

- Boiling point: -28°F (-33°C).

- Easily liquefied under pressure.

- Rapidly absorbs moisture, making it highly irritating to skin, eyes, and respiratory systems.

- **Reactivity:**

- Corrosive to copper, brass, and galvanized materials.

- Reacts violently with water and acids.

- **Behavior in the environment:**

- Vapor is heavier than air and tends to accumulate in low-lying areas.

- Dissolves in water to form ammonium hydroxide, which is caustic.

---

### **3. Hazards of Anhydrous Ammonia**

- **Health hazards:**

- Causes severe burns on contact with skin or eyes.

- Inhalation can lead to respiratory distress, lung damage, or death.

- Prolonged exposure to high concentrations can result in frostbite or chemical burns.

- **Physical hazards:**

- High pressure in storage tanks poses explosion risks.

- Leaks or releases can create dangerous conditions in confined spaces.

---

### **4. Safe Handling Practices**

- **Personal Protective Equipment (PPE):**

- Chemical-resistant gloves and aprons.

- Full-face respirators or goggles to protect eyes.

- Properly rated gas masks for respiratory protection.

- Steel-toed boots and long-sleeved clothing.

- **Proper transfer and storage:**

- Use approved containers and equipment for storage.

- Secure cylinders to prevent tipping or damage.

- Check for leaks with approved methods (e.g., sulfur sticks, ammonia-compatible detectors).

- **Loading and unloading:**

- Follow specific procedures to minimize spills or accidental releases.

- Ensure all valves and hoses are properly connected.

---

### **5. Emergency Preparedness and Response**

- **Spill and leak response:**

- Evacuate the area immediately if a leak occurs.

- Approach the leak from upwind and use approved containment methods.

- Use water spray cautiously to absorb ammonia vapor but avoid excess water to prevent over-reaction.

- **First aid procedures:**

- **Eye contact:** Flush eyes with water for at least 15 minutes and seek immediate medical attention.

- **Skin contact:** Remove contaminated clothing and rinse the skin thoroughly with water.

- **Inhalation:** Move the victim to fresh air and provide oxygen if trained to do so.

- **Firefighting measures:**

- Use water spray to cool tanks exposed to heat.

- Do not extinguish a fire involving anhydrous ammonia unless the leak can be stopped.

---

### **6. Recognizing Signs of Ammonia Exposure**

- **Acute exposure symptoms:**

- Burning sensation in eyes, nose, and throat.

- Difficulty breathing or chest pain.

- Skin irritation or chemical burns.

- **Chronic exposure risks:**

- Prolonged exposure may lead to respiratory sensitivity or damage.

---

### **7. Regulatory Compliance**

- **OSHA standards:** Ensure compliance with OSHA 29 CFR 1910.111 for storage and handling of anhydrous ammonia.

- **Environmental regulations:**

- Report releases exceeding the reportable quantity (RQ) to regulatory authorities.

- Maintain proper documentation for storage and transportation.

- **Training requirements:** Ensure all workers handling anhydrous ammonia are properly trained and certified.

---

### **8. Equipment and Maintenance**

- **Inspecting equipment:**

- Regularly check hoses, fittings, valves, and storage tanks for damage or wear.

- Ensure pressure relief valves are functional and within inspection dates.

- **Storage requirements:**

- Maintain tanks in well-ventilated areas, away from heat sources or incompatible materials.

- Label all containers clearly and store them upright.

---

### **9. Hands-On Training**

- **Leak detection demonstration:**

- Show workers how to identify and respond to leaks safely.

- **Equipment inspection exercise:**

- Practice checking hoses, valves, and fittings for wear and tear.

- **PPE use:**

- Demonstrate proper donning and doffing of protective equipment.

---

### **10. Assessment and Certification**

- **Written or practical exam:**

- Assess knowledge of hazards, handling procedures, and emergency response.

- **Certification:**

- Issue certificates to participants who successfully complete the training.

---

### **11. Questions and Wrap-Up**

- Encourage participants to ask questions about scenarios they may encounter.

- Provide additional resources, such as SDS (Safety Data Sheets) and reference guides.

---

Would you like to include specific examples or scenarios tailored to your industry? Let me know!

-

7:58

7:58

HSESafetyInformation

7 days agoAuthentic Peshawari Rosh _ Namkeen Gosht Recipe __ Traditional KPK and Baluchistan

441 -

3:12:08

3:12:08

MyronGainesX

11 hours ago $31.49 earnedDan Bongino Named As Deputy Director Of FBI And CPAC Recap

94K27 -

3:12:31

3:12:31

vivafrei

10 hours agoBarnes Live from Seattle - Defending Benshoof in a Case that is CRAY CRAY!

143K45 -

2:12:12

2:12:12

Robert Gouveia

10 hours agoLiberals EXPLODE over Elon's Email; Lawsuits FLY; Sanctions?? Congrats Dan!

110K36 -

1:33:36

1:33:36

Redacted News

11 hours agoBREAKING! PUTIN LAUNCHES MASSIVE OFFENSIVE IN UKRAINE AS EUROPEAN LEADERS PUSH FOR MORE WAR

187K252 -

44:39

44:39

Kimberly Guilfoyle

12 hours agoBetter Days Ahead for the FBI, Live with Asm Bill Essayli & John Koufos | Ep.199

118K27 -

1:40:29

1:40:29

In The Litter Box w/ Jewels & Catturd

1 day agoWhat Did You Do Last Week? | In the Litter Box w/ Jewels & Catturd – Ep. 748 – 2/24/2025

155K41 -

23:34

23:34

Stephen Gardner

11 hours ago🔥CNN PANICS over $5000 DOGE Dividend | Trump Orders bigger Audits

98.3K166 -

1:53:54

1:53:54

The White House

13 hours agoPresident Trump Holds a Press Conference with President Emmanuel Macron of France

106K91 -

1:48:31

1:48:31

The Officer Tatum

13 hours agoLIVE MSNBC DROPS HAMMER On Joy Reid as STAFFERS PANIC! + More Ep 67

136K89