Premium Only Content

Trenching and Excavation Training

### **Trenching and Excavation Safety Training Outline**

This training program aims to educate workers about the hazards of trenching and excavation activities and provide practical knowledge to minimize risks and comply with safety standards.

---

### **1. Introduction to Trenching and Excavation Safety**

- **Purpose of training:**

- Protect workers from potential hazards.

- Ensure compliance with OSHA standards (e.g., OSHA 1926 Subpart P).

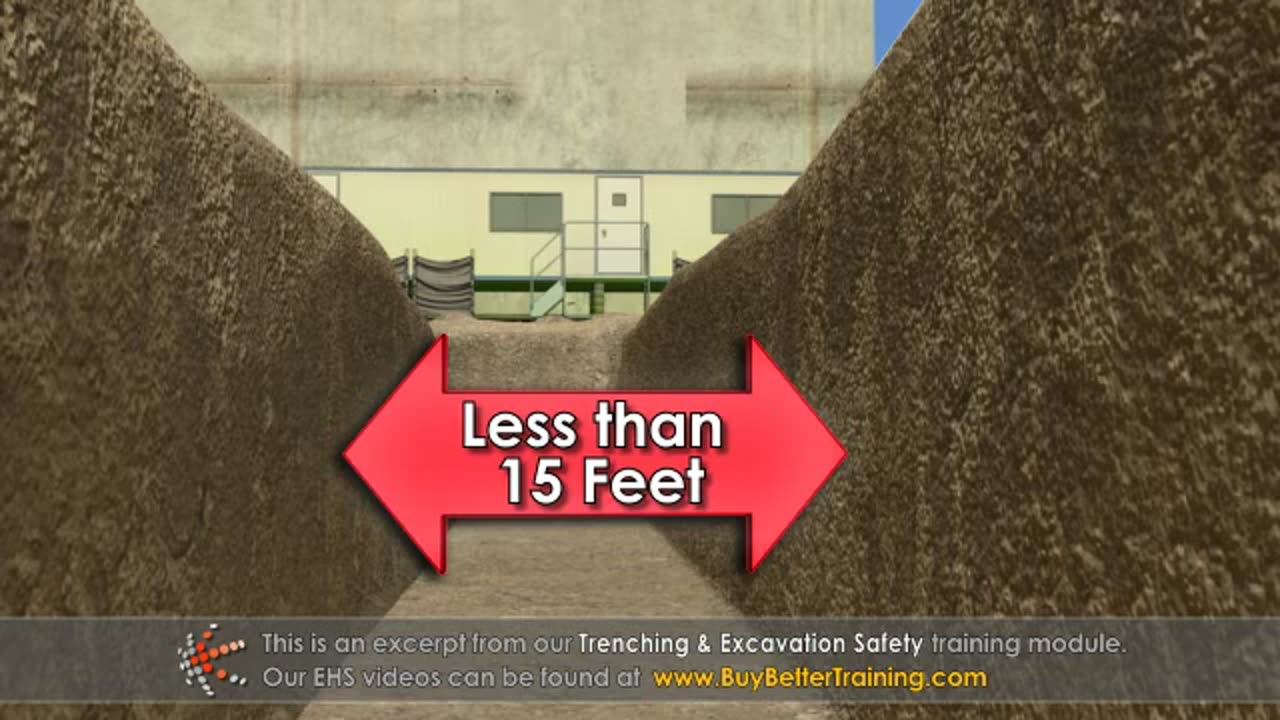

- **Definition:**

- **Trench:** A narrow excavation (depth greater than width, less than 15 feet wide).

- **Excavation:** Any man-made cut, cavity, trench, or depression in the earth's surface.

- **Importance of safety in trenching and excavation:**

- Risks of collapse, injuries, and fatalities.

- Highlight relevant statistics.

---

### **2. Hazards Associated with Trenching and Excavation**

- **Cave-ins:** The most common and deadly hazard.

- **Falling loads:** Tools, equipment, or materials falling into the trench.

- **Hazardous atmospheres:** Lack of oxygen, toxic gases, or flammable materials.

- **Water accumulation:** Flooding or erosion weakening trench walls.

- **Utility strikes:** Contact with underground utilities like gas, water, or electrical lines.

- **Vehicular hazards:** Equipment or traffic near the excavation site.

---

### **3. Pre-Planning and Site Preparation**

- **Competent person:** A trained individual responsible for identifying hazards and implementing corrective measures.

- **Pre-work inspections:**

- Assess soil type and stability.

- Identify underground utilities using locators or utility maps.

- Evaluate weather conditions.

- **Permits and notifications:** Ensure required permits are obtained and notifications to local utility companies are made.

---

### **4. Protective Systems**

- **Types of protective systems:**

- **Sloping:** Cutting the trench walls at an angle away from the excavation.

- **Shoring:** Installing supports to prevent cave-ins.

- **Shielding:** Using trench boxes to protect workers from collapsing walls.

- **Selection of protective systems based on:**

- Soil classification.

- Depth and width of the trench.

- Water conditions.

---

### **5. Soil Classification**

- **Types of soil:**

- **Stable rock:** Natural solid material.

- **Type A soil:** Most stable (e.g., clay, silty clay).

- **Type B soil:** Medium stability (e.g., silt, sandy clay).

- **Type C soil:** Least stable (e.g., gravel, sand).

- **Testing methods:**

- Manual (visual inspection, pocket penetrometer).

- Laboratory analysis.

---

### **6. Safe Work Practices**

- **Access and egress:**

- Ladders, ramps, or stairways must be provided every 25 feet for trenches deeper than 4 feet.

- **Distance from trench edges:**

- Place spoil piles, tools, and equipment at least 2 feet away.

- **Monitoring conditions:**

- Continuous assessment of the trench, especially after rain or vibrations.

- **Prohibited activities:**

- No working under suspended loads.

- No unprotected entry into trenches deeper than 5 feet.

---

### **7. Emergency Preparedness**

- **Response to cave-ins:**

- Do not attempt to rescue trapped workers without proper equipment and training.

- Call emergency services immediately.

- **First aid:** Treat injuries while waiting for professional help.

- **Evacuation plans:** Establish clear communication and exit strategies.

---

### **8. Roles and Responsibilities**

- **Workers:**

- Follow instructions and use protective systems.

- Report hazards or unsafe conditions immediately.

- **Supervisors:**

- Conduct regular inspections.

- Ensure protective systems are in place and workers are trained.

- **Competent person:**

- Evaluate soil, protective systems, and overall safety.

---

### **9. Equipment Safety**

- **Heavy machinery:** Ensure proper operation and regular maintenance.

- **Utility detection tools:** Use equipment to locate underground hazards accurately.

- **Protective gear:** Wear appropriate PPE (helmets, steel-toed boots, high-visibility clothing).

---

### **10. Regulatory Compliance**

- Overview of OSHA trenching and excavation standards:

- Protective system requirements.

- Inspections by a competent person.

- Proper design and depth limits for trenches.

---

### **11. Hands-On Training**

- **Site walkthrough:** Identify potential hazards in a simulated or real trench site.

- **Soil testing demonstration:** Perform simple soil classification tests.

- **Protective system installation:** Show how to set up trench boxes or shoring systems.

---

### **12. Assessment and Certification**

- Conduct a written or practical evaluation.

- Issue certificates for successful participants.

---

Would you like this training tailored for a specific industry or include detailed hands-on exercises? Let me know!

-

1:35

1:35

HSESafetyInformation

17 days agoMutton Chops two ways- baked & grilled Recipe by Food Fusion (Eid Recipe)

49 -

47:39

47:39

Michael Franzese

4 hours agoJewelry King Trax NYC EXPOSES How the Powerful Steal from You

45.3K8 -

LIVE

LIVE

Slightly Offensive

3 hours ago $2.86 earnedCandace REDPILLS the Masses in BOMBSHELL Theo Von Interview | Guest: Shane Cashman

1,149 watching -

LIVE

LIVE

megimu32

3 hours agoON THE SUBJECT: IRL Streamers Attacked & Nostalgic Animal Movies That Made Us Cry

595 watching -

1:00:54

1:00:54

The Tom Renz Show

7 hours agoMore Epstein/FBI, a Scary Trade War, & the Dem Echo Chamber

7.49K1 -

40:43

40:43

Kimberly Guilfoyle

8 hours agoDems Double Down on Delusion-Why? Live with Tony Kinnett & Bo French | Ep.202

77.8K31 -

1:28:42

1:28:42

Redacted News

6 hours agoBREAKING! SOMETHING BIG IS HAPPENING IN EUROPE ALL OUT WAR IS COMING AGAINST RUSSIA, TRUMP FURIOUS

121K282 -

47:50

47:50

Candace Show Podcast

6 hours agoBREAKING: Judge Makes Statement Regarding Taylor Swift's Text Messages. | Candace Ep 155

113K112 -

1:14:23

1:14:23

Josh Pate's College Football Show

3 hours ago $0.29 earnedCFB’s Most Hated Teams | FSU & Clemson Future | Big Ten Win Totals | Star Rankings Overrated?

14.5K -

1:33:47

1:33:47

CatfishedOnline

5 hours agoGoing Live With Robert - Weekly Recap

27.8K