Premium Only Content

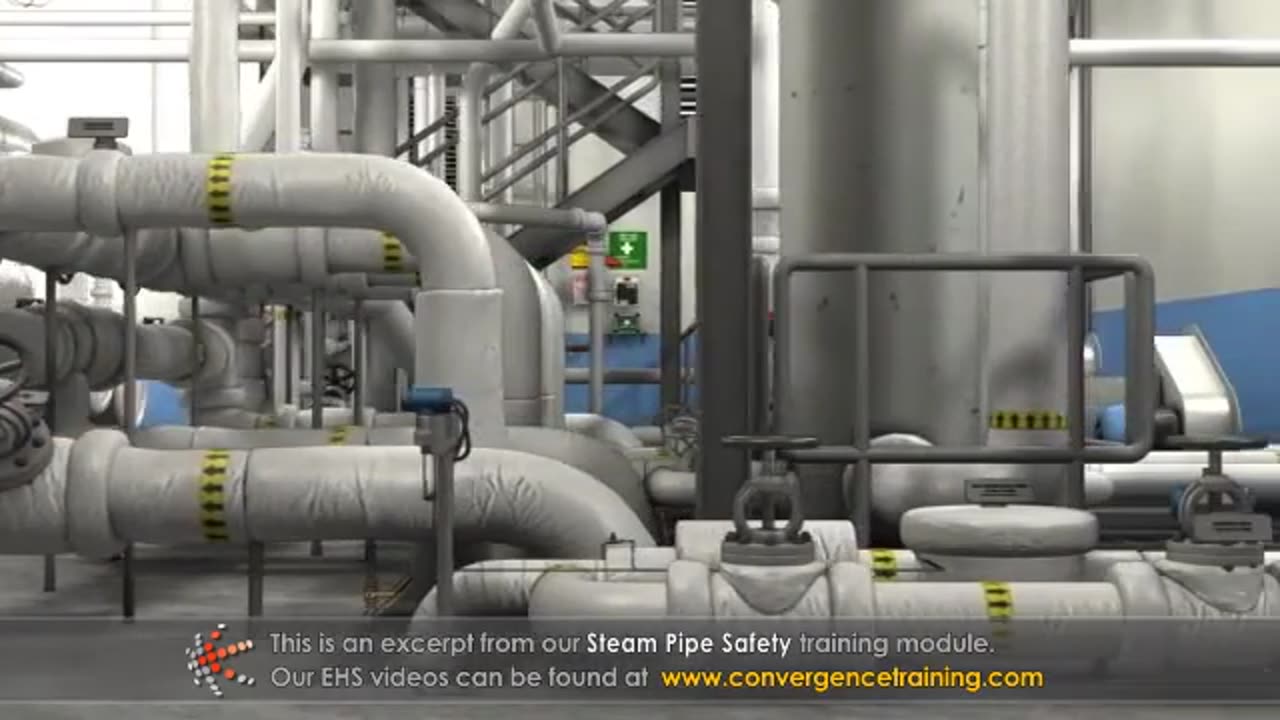

Steam Pipe Safety Training

**Steam Pipe Safety Training** is critical to prevent injuries and ensure the safe operation of systems involving high-pressure and high-temperature steam. This training focuses on recognizing hazards, following safe work practices, and knowing emergency protocols. Below is a detailed guide:

---

### **1. Objectives of the Training**

- Educate workers about the risks associated with steam pipes.

- Teach safe handling, maintenance, and inspection procedures.

- Highlight emergency response actions for steam-related incidents.

- Promote compliance with safety regulations and standards.

---

### **2. Common Hazards with Steam Pipes**

- **High Temperatures**: Direct contact can cause severe burns.

- **Pressure Hazards**: Pipe bursts or leaks can release high-pressure steam.

- **Condensate Burns**: Hot water formed in pipes can cause scalds.

- **Noise and Vibrations**: High-pressure steam flow can create dangerous noise levels and vibrations.

- **Pipe Failures**: Corrosion, wear, or improper maintenance can lead to leaks or explosions.

---

### **3. Personal Protective Equipment (PPE)**

- **Mandatory PPE**:

- Heat-resistant gloves.

- Safety goggles or face shields (protect eyes from steam or debris).

- Long-sleeve, flame-resistant clothing.

- Steel-toed boots.

- **Optional PPE**:

- Hearing protection in high-noise areas.

- Respirators if working in enclosed spaces with possible steam or vapor exposure.

---

### **4. Key Safety Practices**

#### **a. Installation and Design**

- Ensure steam pipes are designed to withstand operating pressure and temperature.

- Install pressure relief valves to prevent over-pressurization.

- Use proper insulation to minimize heat transfer and protect workers.

#### **b. Inspection and Maintenance**

- Perform regular inspections for:

- Leaks, corrosion, or worn-out gaskets.

- Damaged insulation or pipe supports.

- Check pressure gauges and temperature indicators for accuracy.

- Maintain proper drainage to prevent condensate buildup.

- Follow a preventive maintenance schedule for valves, joints, and seals.

#### **c. Safe Work Practices**

- Never touch steam pipes or fittings directly; use tools or insulated handles.

- Avoid standing in front of valves or pipe fittings where leaks may occur.

- Depressurize and cool pipes before performing maintenance.

- Tag and lockout steam systems during repairs to prevent accidental activation.

- Use caution when opening valves to avoid sudden steam release.

#### **d. Temperature and Pressure Monitoring**

- Ensure systems have functioning gauges and alarms for temperature and pressure.

- Monitor for abnormal noises, pressure drops, or vibrations, which can indicate issues.

---

### **5. Emergency Preparedness**

- **In Case of Steam Leaks**:

- Evacuate the area immediately.

- Shut off the steam supply from a safe location if trained to do so.

- Report the incident to the supervisor or safety officer.

- **In Case of Burns**:

- Remove the injured person from the source of steam.

- Cool the affected area with cool (not cold) water.

- Seek immediate medical attention.

- **Pipe Rupture**:

- Shut down the system and evacuate the area.

- Do not approach the pipe until it has cooled and pressure has been released.

---

### **6. Regulatory Compliance**

- Adhere to OSHA standards for steam systems and pressure vessels (e.g., OSHA CFR 1910.261).

- Follow ASME (American Society of Mechanical Engineers) codes for piping design and maintenance.

- Ensure compliance with local regulations regarding steam system operation.

---

### **7. Training Delivery Methods**

- **Classroom Training**:

- Use diagrams, videos, and case studies to explain steam pipe components, hazards, and best practices.

- **Hands-On Training**:

- Demonstrate safe operation and inspection of steam systems.

- Practice lockout/tagout procedures on a steam system.

- **Toolbox Talks**:

- Conduct brief sessions on specific topics like handling steam leaks or using PPE.

---

### **8. Follow-Up and Refresher Training**

- Periodically review and update training materials based on incident reports or new equipment.

- Conduct annual refresher courses to reinforce knowledge and skills.

- Audit steam systems regularly to ensure safety protocols are being followed.

---

Would you like assistance in creating detailed lesson plans, safety posters, or checklists for steam pipe operations?

-

49:33

49:33

Candace Show Podcast

2 hours agoI Respond To Mr. And Mr. Macron | Candace Ep 131

16.9K58 -

LIVE

LIVE

Revenge of the Cis

3 hours agoEpisode 1429: Catch And Release

2,221 watching -

LIVE

LIVE

Film Threat

8 hours agoVERSUS: HOLLYWOOD IS STILL ON FIRE | Film Threat Versus

209 watching -

12:33

12:33

Silver Dragons

2 hours agoSilver Price Crushed Today - NEW TREND STARTING?

2.27K -

1:02:03

1:02:03

In The Litter Box w/ Jewels & Catturd

21 hours agoRecall Newscum & Bass! | In the Litter Box w/ Jewels & Catturd – Ep. 718 – 1/13/2025

64.3K24 -

3:19:58

3:19:58

Tate Speech by Andrew Tate

9 hours agoEMERGENCY MEETING EPISODE 101 - STRENGTH AND HONOR

156K64 -

1:48:09

1:48:09

The Quartering

5 hours agoLA Fires Are About To Get Way Worse, Trump Vs Vance On J6 Pardons, Brett Cooper Bombshell & More

98.6K36 -

LIVE

LIVE

Dr Disrespect

6 hours ago🔴LIVE - DR DISRESPECT - MARVEL RIVALS - TOP 500 IN THE WORLD

2,929 watching -

1:05:49

1:05:49

MTNTOUGH Fitness Lab

7 hours agoDamon West: How Faith and Mental Toughness Helped Me Escape Prison | MTNPOD #99

6.49K -

1:43:05

1:43:05

The Criminal Connection Podcast

7 hours agoIAN MCCRANOR: World Champion Karate Doorman CRAZY Life Story, Mob Hits GONE WRONG & Video Game Star!

5.58K1