Premium Only Content

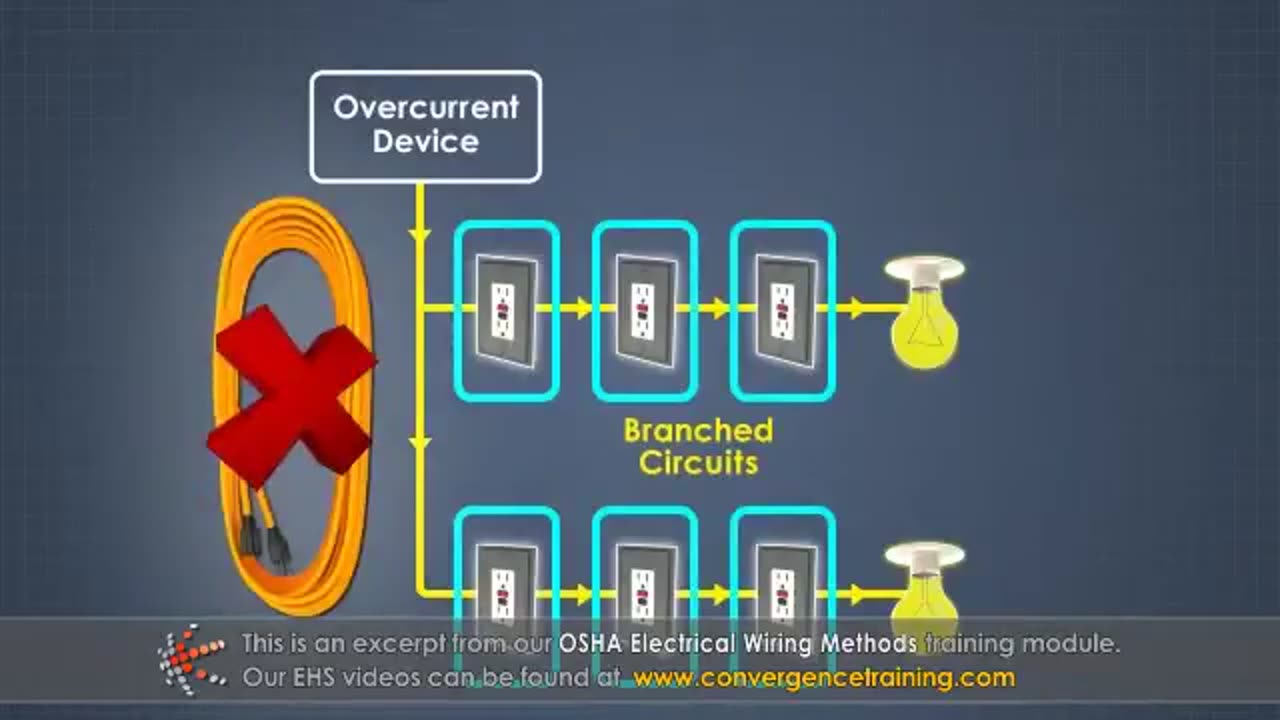

OSHA Electrical Wiring Methods Training

**OSHA Electrical Wiring Methods Training** is designed to ensure compliance with OSHA standards and promote safe electrical wiring practices in workplaces. Below is a detailed outline for this training:

---

### **1. Overview of OSHA Standards for Electrical Wiring**

- Introduction to OSHA's electrical safety standards (29 CFR 1910 Subpart S and 1926 Subpart K).

- Key definitions: grounding, bonding, circuit, conduit, etc.

- Importance of compliance in preventing accidents and ensuring workplace safety.

---

### **2. Basics of Electrical Wiring Systems**

- Types of wiring systems (e.g., residential, commercial, industrial).

- Common electrical wiring methods:

- Rigid Metal Conduit (RMC).

- Electrical Metallic Tubing (EMT).

- Nonmetallic-Sheathed Cable (NM).

- Flexible Metal Conduit (FMC).

- Armored Cable (AC) and Metal-Clad Cable (MC).

- Conductors and insulation materials.

---

### **3. OSHA Requirements for Electrical Wiring Methods**

- **General Provisions**:

- Use of approved wiring materials and devices.

- Installation methods to prevent physical damage and exposure to hazards.

- **Grounding and Bonding**:

- Ensuring proper grounding of electrical systems.

- Differences between grounding and bonding.

- **Protection and Securement**:

- Proper securement of conduits, cables, and boxes.

- Installation of wiring above ground and within walls.

- **Environment-Specific Requirements**:

- Wiring in wet or hazardous locations.

- Explosion-proof wiring in flammable environments.

---

### **4. Electrical Installation Best Practices**

- Maintaining clearance distances around electrical panels.

- Avoiding overloading circuits and following circuit rating guidelines.

- Proper labeling of circuits, wires, and disconnect switches.

- Avoiding sharp bends and excessive pulling of wires.

---

### **5. Common Violations and Hazards**

- Examples of non-compliance (e.g., exposed wires, damaged insulation).

- Consequences of improper wiring (shocks, fires, equipment failure).

- Real-world case studies of wiring-related incidents.

---

### **6. Personal Protective Equipment (PPE)**

- Importance of PPE during wiring tasks.

- Use of insulated gloves, eye protection, and flame-resistant clothing.

- Ensuring tools and equipment are rated for electrical work.

---

### **7. Inspection and Maintenance of Electrical Wiring**

- Conducting regular inspections for wear and damage.

- Testing for continuity and grounding integrity.

- Maintenance practices to extend the lifespan of wiring systems.

---

### **8. Emergency Procedures and Reporting**

- Steps to take in the event of an electrical fire or accident.

- Reporting unsafe wiring practices or equipment failures.

- Documenting corrective actions.

---

### **9. OSHA Resources and Training Recap**

- Review of OSHA handbooks, fact sheets, and resources.

- Recap of key wiring safety practices and standards.

- Q&A session for participant engagement.

---

**Optional Add-ons**:

- **Hands-On Training**: Demonstrations of proper wiring methods and equipment use.

- **Assessment Quiz**: A brief quiz to test understanding of OSHA requirements.

- **Certification**: Provide certificates upon completion of training.

Would you like assistance creating specific training materials, such as slides, videos, or assessment tools?

-

1:35

1:35

HSESafetyInformation

1 month agoMutton Chops two ways- baked & grilled Recipe by Food Fusion (Eid Recipe)

57 -

24:47

24:47

World2Briggs

23 hours ago10 Cities Where The High Cost Of Living Just Isn't Worth It

1333 -

LIVE

LIVE

SoundBoardLord

2 hours agoSaturday Variety Gaming with Friends!!

177 watching -

8:35

8:35

ARFCOM News

22 hours ago $0.04 earnedThis Is How We End The NFA | Booker's Hypocrisy | ATF Facial Recognition

3574 -

10:51

10:51

IsaacButterfield

1 day ago $0.20 earnedToddler Expelled From School For Being “Transphobic”

1.18K5 -

24:52

24:52

Degenerate Jay

20 hours agoIs Marvel Ruining Venom Now? Why Is Mary Jane Venom?

2283 -

2:11:46

2:11:46

Rotella Games

3 hours agoSaturday Morning Family Friendly Fortnite

7.38K1 -

1:10:16

1:10:16

Squaring The Circle, A Randall Carlson Podcast

3 hours agoEP043-PT2: A Biographical Look Into The Life of Randall Carlson With Guest Warren Steury

3712 -

1:00:30

1:00:30

Trumpet Daily

1 day ago $3.00 earnedA World Economy Based on Competition - Trumpet Daily | Apr. 4, 2025

2.57K8 -

10:58

10:58

Gun Drummer

20 hours ago17 Round Shotgun - IWI TS12

103