Premium Only Content

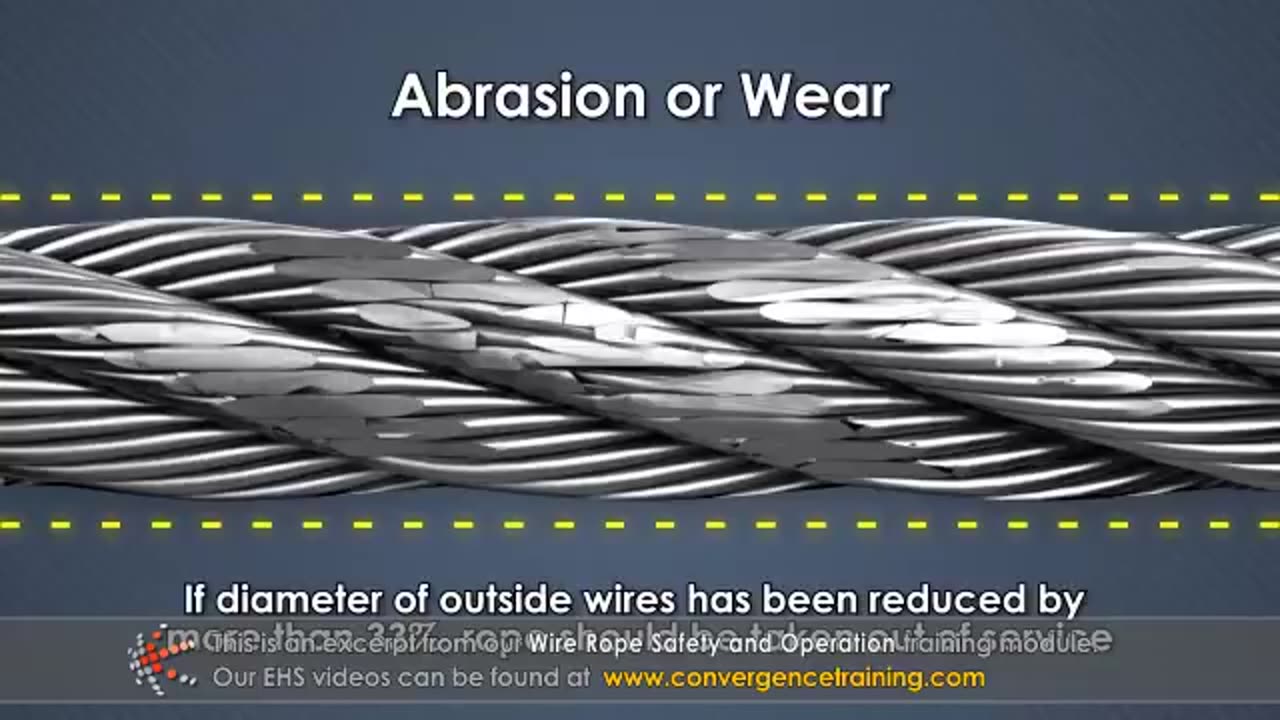

Wire Rope Safety and Operation Training

Wire rope safety and operation training focuses on the proper use, maintenance, and safety measures for wire ropes to prevent accidents and extend their service life. Below is a detailed outline for this training:

---

## **1. Overview of Wire Rope Safety**

- **Purpose**: Ensuring the safe use of wire ropes in lifting, hoisting, and securing applications.

- **Key Risks**:

- Wire rope failure due to overloading, wear, or improper handling.

- Injuries from snapped wires, kinks, or uncontrolled loads.

---

## **2. Safety Guidelines for Wire Rope Use**

- **Load Limits**:

- Never exceed the **Working Load Limit (WLL)**.

- Always account for dynamic loading factors (shock loading, sudden stops).

- **Angle of Operation**:

- Avoid extreme angles that can increase tension and reduce WLL.

- **Inspection**:

- Inspect wire ropes before each use (broken wires, kinks, corrosion).

- **Anchoring**:

- Ensure proper attachment to secure points using appropriate fittings.

---

## **3. Proper Handling of Wire Rope**

- **Uncoiling**:

- Use a reel or turntable to prevent kinks or twists.

- **Storage**:

- Store in a clean, dry area, away from chemicals and moisture.

- **Spooling**:

- Wind evenly on a drum; ensure no crossovers or pinching.

- **Lubrication**:

- Apply appropriate lubricant to reduce friction and prevent corrosion.

---

## **4. Common Hazards and How to Avoid Them**

- **Overloading**:

- Use properly rated wire ropes for the intended load.

- **Wear and Tear**:

- Monitor for visible signs of damage.

- **Shock Loading**:

- Avoid rapid load application to prevent sudden failure.

- **Improper Installation**:

- Use compatible fittings and ensure correct tensioning.

- **Environment**:

- Avoid exposure to corrosive environments without proper protection.

---

## **5. Inspection and Maintenance**

- **Daily Inspection**:

- Look for broken wires, flattening, corrosion, and kinks.

- **Periodic Inspection**:

- Conduct more detailed checks based on usage and environmental exposure.

- **Replacement Criteria**:

- Broken wires exceed the allowed limit.

- Excessive stretching or deformation.

- Visible core damage or severe corrosion.

---

## **6. Emergency Situations**

- **Rope Failure**:

- Secure the area and ensure all personnel are at a safe distance.

- **Load Drop**:

- Use signal communication to warn nearby workers.

- **Entanglement**:

- Stop operations immediately and resolve the issue safely.

---

## **7. Personal Protective Equipment (PPE)**

- **Gloves**: Protect against sharp strands.

- **Safety Helmets**: Guard against falling loads.

- **Steel-Toe Boots**: Shield feet from heavy objects.

- **Eye Protection**: Prevent injuries from snapped wires or debris.

---

## **8. Training on Wire Rope Operation**

- **Lifting and Hoisting**:

- Proper attachment to hooks, shackles, and slings.

- Safe lifting angles and avoiding side loading.

- **Tensioning**:

- Avoid over-tensioning; use calibrated equipment.

- **Load Control**:

- Use taglines to guide loads and prevent swinging.

---

## **9. Regulatory Compliance**

- Follow standards such as:

- OSHA regulations (Occupational Safety and Health Administration).

- ASME B30.9 (Slings) and B30.5 (Mobile Cranes).

- ISO 4309 (Wire ropes for cranes).

---

## **10. Practical Demonstrations**

- **Inspection Process**: Hands-on checks for wear, broken wires, and other issues.

- **Load Testing**: Demonstrating safe WLL and dynamic loading.

- **Proper Spooling**: Training on reel handling and even winding.

---

Would you like a tailored training manual, slide deck, or visual aids (e.g., diagrams or infographics) for this topic?

-

7:58

7:58

HSESafetyInformation

20 days agoAuthentic Peshawari Rosh _ Namkeen Gosht Recipe __ Traditional KPK and Baluchistan

521 -

2:01:46

2:01:46

vivafrei

5 hours agoEp. 254: China to Pay $24 BILLION? Who Owns Embryos? Tulsi was RIGHT on Syria! Prorogation & MORE!

117K82 -

3:40:55

3:40:55

MyronGainesX

15 hours ago $1.55 earnedFormer Fed Explains Gabby Petito's Murder

51.6K17 -

2:18:05

2:18:05

Nerdrotic

6 hours ago $0.99 earnedInvestigations into the Unknown with Micah Hanks | Forbidden Frontier #093

56.2K16 -

18:54

18:54

The Rubin Report

10 hours agoHow One Woman Outsmarted Pornhub & Exposed Its Dark Secrets | Laila Mickelwait

125K94 -

LIVE

LIVE

Major League Fishing

5 days agoLIVE! - Bass Pro Tour: Stage 3 - Day 4

638 watching -

1:05:28

1:05:28

Sports Wars

13 hours agoLebron GOES OFF Over Bronny Hate, Pereira LOSES Belt To Ankalaev At UFC 313, Xavier Worthy Arrested

92.5K11 -

10:27

10:27

Tactical Advisor

1 day agoDMR or SPR for Civilian Use?

92.7K6 -

8:21

8:21

DEADBUGsays

1 day agoThe Crossbow Killer

89.2K13 -

8:40

8:40

Tundra Tactical

1 day ago $2.88 earnedThe Executive Order Wishlist.

95.8K6