Premium Only Content

AC Motor Operation and Types

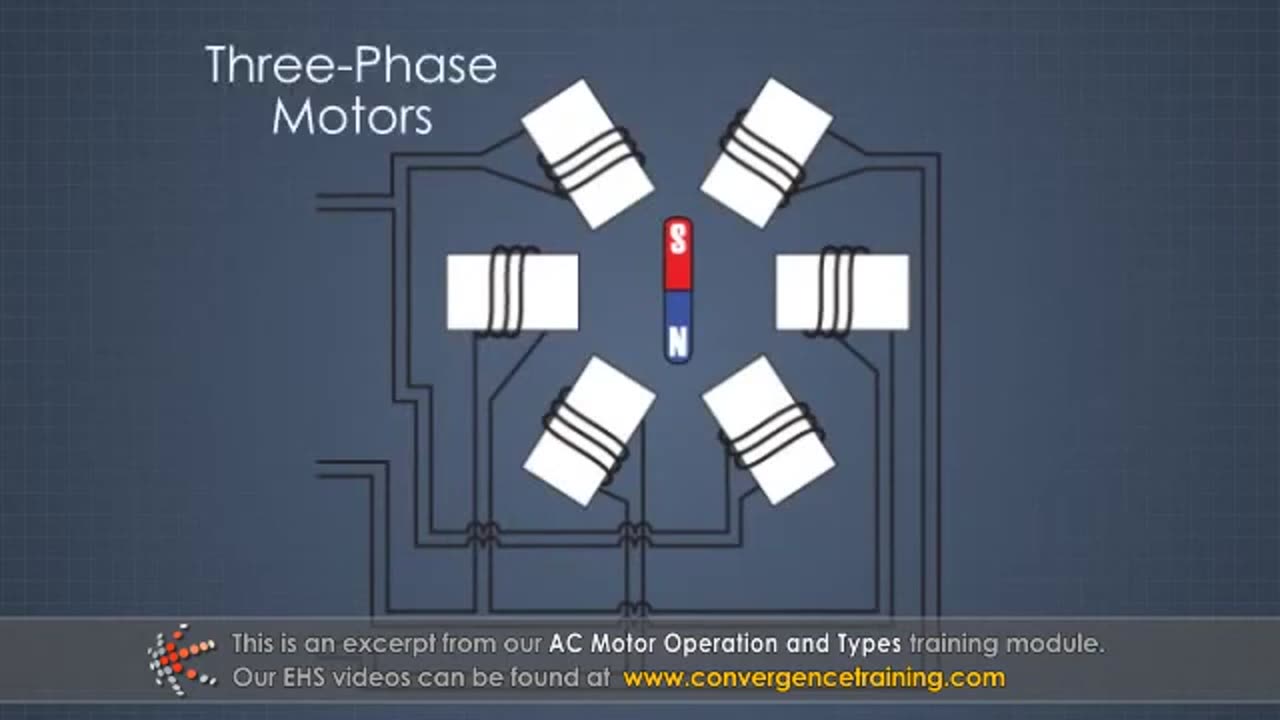

### **AC Motor Operation**

AC motors convert electrical energy into mechanical energy using alternating current (AC). They are widely used because of their efficiency, durability, and versatility.

---

### **How AC Motors Work**

1. **Basic Components**:

- **Stator**: The stationary part that generates a rotating magnetic field using AC power.

- **Rotor**: The rotating part that responds to the magnetic field, creating motion.

- **Shaft**: Transfers the mechanical power produced by the rotor to an external load.

- **Bearings and Frame**: Support and protect the motor components.

2. **Principle of Operation**:

- When AC is supplied to the stator, it produces a rotating magnetic field.

- This magnetic field induces a current in the rotor through electromagnetic induction (Faraday’s Law).

- The interaction between the stator's magnetic field and the current in the rotor generates torque, causing the rotor to spin.

3. **Speed and Synchronization**:

- The speed of the rotor depends on the frequency of the AC supply and the number of poles in the motor.

- Rotor speed is slightly less than the stator's magnetic field speed (synchronous speed) in most AC motors.

---

### **Types of AC Motors**

AC motors are categorized based on their operation and construction:

#### **1. Induction Motors (Asynchronous Motors)**

- Most common type of AC motor.

- The rotor doesn’t receive direct electrical power; it relies on induction from the stator's magnetic field.

**Subtypes**:

- **Single-Phase Induction Motors**:

- Used in small appliances like fans and pumps.

- Types: Split-phase, capacitor-start, shaded-pole.

- **Three-Phase Induction Motors**:

- Widely used in industrial applications.

- Robust, efficient, and suitable for heavy loads.

**Advantages**:

- Simple and rugged construction.

- Requires minimal maintenance.

- Cost-effective.

#### **2. Synchronous Motors**

- The rotor speed matches the speed of the stator's magnetic field (synchronous speed).

- Requires an additional DC excitation to the rotor for synchronization.

**Applications**:

- Power factor correction.

- Precise speed control in industries like robotics and automation.

**Advantages**:

- Constant speed operation.

- High efficiency under load.

#### **3. Special-Purpose Motors**

- **Universal Motors**:

- Can run on AC or DC.

- Common in portable tools like drills and mixers.

- **Stepper Motors**:

- Precise control of position and speed.

- Used in printers, CNC machines, and robotics.

- **Servo Motors**:

- High-speed and precision control for automation and robotics.

---

### **Advantages of AC Motors**

- **Durability**: Less wear and tear due to fewer moving parts.

- **Efficiency**: High energy efficiency in three-phase motors.

- **Versatility**: Can be designed for specific speeds and torque requirements.

- **Cost-Effectiveness**: Cheaper than DC motors for similar power ratings.

---

### **Applications of AC Motors**

1. **Industrial**: Conveyor belts, pumps, compressors, and machine tools.

2. **Home Appliances**: Refrigerators, washing machines, and air conditioners.

3. **Transportation**: Electric trains and escalators.

4. **HVAC**: Fans, blowers, and chillers.

---

Let me know if you’d like more details about specific motor types, their wiring diagrams, or how to select an AC motor for an application! 😊

-

LIVE

LIVE

2 MIKES LIVE

2 hours agoTHE MIKE SCHWARTZ SHOW with DR. MICHAEL J SCHWARTZ 01-21-2025

445 watching -

29:44

29:44

Neil McCoy-Ward

3 hours ago🔥 Day 2... And Things Are Heating UP!!! 🚨

4.07K2 -

27:22

27:22

BonginoReport

2 hours agoA Nation Reclaimed (Ep.122) - 01/21/2025

48.8K55 -

1:32:27

1:32:27

Game On!

10 hours ago $2.71 earnedOhio State DOMINATES Notre Dame! Chip Kelly FINALLY wins a National Championship!

33.5K3 -

48:58

48:58

World Nomac

19 hours agoWhat happens in the Philippines AFTER DARK 🇵🇭

61.2K4 -

40:28

40:28

Rethinking the Dollar

1 day agoTrump’s 200 Executive Orders (420+ & Counting): What’s Next for America?

67.1K25 -

1:48:38

1:48:38

The Criminal Connection Podcast

1 day ago $3.13 earnedYUSEF BOUATTOURA Pro PT: Mean Streets of TOTTENHAM, Belmarsh to Bootcamp! (CRAZY Life Story)

54.4K2 -

10:33

10:33

Silver Dragons

19 hours agoDealer Reveals 2025 Silver and Gold Prediction, Goals, & MORE!

33.7K7 -

1:08:13

1:08:13

Trumpet Daily

23 hours ago $5.83 earnedThe Return of 45 - Trumpet Daily | Jan. 20, 2025

28.3K7 -

1:16:47

1:16:47

BIG NEM

1 day agoWe Interviewed a 40 Year Old VIRGIN

52.6K3