Premium Only Content

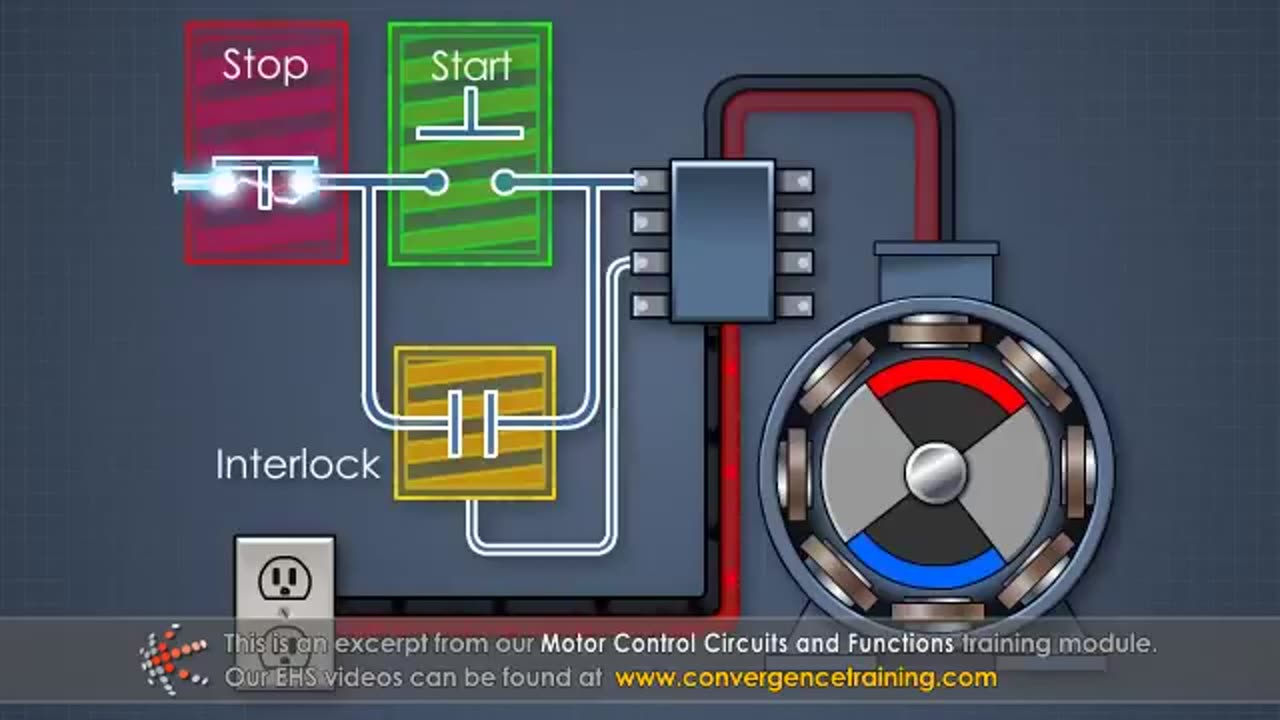

Motor Control Circuits and Functions

A **motor control circuit** is designed to start, stop, and control the speed or direction of an electric motor. These circuits are widely used in industrial automation, robotics, and machinery. Here's a detailed breakdown:

---

### **Key Components of Motor Control Circuits**

1. **Power Supply**: Provides the necessary electrical energy for the motor.

2. **Motor**: Converts electrical energy into mechanical motion.

3. **Switching Devices**:

- **Contactors**: Electromagnetic switches used to start/stop motors by connecting/disconnecting power.

- **Relays**: Smaller switches that control circuits based on input signals.

4. **Protection Devices**:

- **Overload Relays**: Protect motors from overheating or excessive current.

- **Fuses/Circuit Breakers**: Prevent damage caused by short circuits or overcurrent.

5. **Control Devices**:

- **Push Buttons**: Manual start/stop controls.

- **Selector Switches**: Allow selection between modes (e.g., forward/reverse).

- **Sensors**: Detect motor conditions like speed, position, or load.

6. **Control Circuit**: The low-voltage part of the system that handles commands and logic.

7. **Wiring**: Connects components within the circuit.

---

### **Functions of Motor Control Circuits**

1. **Starting the Motor**:

- **Direct On-Line (DOL) Starter**: Simple circuit for starting small motors directly at full voltage.

- **Star-Delta Starter**: Reduces starting current for large motors by initially connecting in a "star" configuration and later switching to "delta."

- **Soft Starters**: Gradually increase voltage to avoid sudden inrush current.

2. **Stopping the Motor**:

- Controlled using stop buttons or safety switches.

- Some circuits include braking mechanisms (e.g., dynamic or regenerative braking).

3. **Speed Control**:

- **Variable Frequency Drives (VFDs)**: Adjust motor speed by varying input frequency and voltage.

- **Resistive Control**: Uses resistors to limit power (common in DC motors).

4. **Direction Control**:

- Use **reversing contactors** to change motor direction by swapping the connections of motor phases.

5. **Protection**:

- Detects faults like overloads, phase loss, or voltage imbalances and disconnects the motor to prevent damage.

6. **Automation**:

- Control motor operation based on external signals (e.g., sensors or timers) in automated systems.

---

### **Types of Motor Control Circuits**

1. **Manual Control**:

- Operated directly by a person using switches or push buttons.

2. **Automatic Control**:

- Operates without human intervention based on programmed logic (e.g., PLC or timers).

3. **Remote Control**:

- Operates motors from a distance using wired or wireless controls.

4. **Programmable Control**:

- Uses advanced controllers like PLCs (Programmable Logic Controllers) or HMIs (Human-Machine Interfaces) for complex operations.

---

### **Examples of Motor Control Circuits**

1. **DOL Starter Circuit**:

- Simplest motor starter circuit with a contactor, overload relay, and push buttons.

2. **Reversing Starter Circuit**:

- Includes two contactors and an interlocking mechanism to change motor direction.

3. **VFD Circuit**:

- Incorporates a VFD for speed control and smooth motor operation.

---

### **Applications of Motor Control Circuits**

- **Industrial Automation**: Conveyor belts, robotics, assembly lines.

- **HVAC Systems**: Fans, pumps, and compressors.

- **Transportation**: Electric trains, elevators, and escalators.

- **Home Appliances**: Washing machines, mixers, and air conditioners.

---

Motor control circuits are foundational in any system requiring electric motors. Let me know if you’d like to explore wiring diagrams, specific configurations, or troubleshooting tips! 😊

-

1:25:53

1:25:53

Kim Iversen

3 days agoStriking Back: Taking on the ADL’s Anti-Free Speech Agenda

74K34 -

49:35

49:35

Donald Trump Jr.

12 hours agoA New Golden Age: Countdown to Inauguration Day | TRIGGERED Ep.202

154K170 -

1:14:34

1:14:34

Michael Franzese

11 hours agoWhat's Behind Biden's Shocking Death Row Pardons?

68.7K43 -

9:49

9:49

Tundra Tactical

9 hours ago $15.74 earnedThe Best Tundra Clips from 2024 Part 1.

88.6K7 -

1:05:19

1:05:19

Sarah Westall

9 hours agoDying to Be Thin: Ozempic & Obesity, Shedding Massive Weight Safely Using GLP-1 Receptors, Dr. Kazer

78.5K20 -

54:38

54:38

LFA TV

1 day agoThe Resistance Is Gone | Trumpet Daily 12.26.24 7PM EST

57.3K9 -

58:14

58:14

theDaily302

18 hours agoThe Daily 302- Tim Ballard

57.1K9 -

13:22

13:22

Stephen Gardner

12 hours ago🔥You'll NEVER Believe what Trump wants NOW!!

106K273 -

54:56

54:56

Digital Social Hour

1 day ago $10.83 earnedDOGE, Deep State, Drones & Charlie Kirk | Donald Trump Jr.

59.2K5 -

DVR

DVR

The Trish Regan Show

13 hours agoTrump‘s FCC Targets Disney CEO Bob Iger Over ABC News Alleged Misconduct

64.2K38