Premium Only Content

Hydraulic System Equipment

### **Hydraulic System Equipment: Components and Their Functions**

Hydraulic systems use pressurized fluid to perform work, offering efficient, high-force mechanical power in various industrial, automotive, and construction applications. Key equipment in a hydraulic system ensures fluid is generated, controlled, and directed to perform tasks like lifting, pushing, or rotating. Below is an overview of the primary components of a hydraulic system and their functions.

---

### **1. Hydraulic Pump**

The hydraulic pump is the heart of the hydraulic system. It converts mechanical energy into hydraulic energy by drawing fluid from the reservoir and pressurizing it for use in the system.

#### **Types of Hydraulic Pumps:**

- **Gear Pumps:** Simple, reliable, and cost-effective, gear pumps use two interlocking gears to generate fluid flow.

- **Vane Pumps:** Utilize a rotating vane inside a housing to generate fluid movement. Known for smooth, consistent flow.

- **Piston Pumps:** Provide high pressure and efficiency, using pistons to create fluid flow. These are often used in high-demand applications.

#### **Functions:**

- **Convert Mechanical Power:** The pump’s primary role is to convert rotational mechanical power (from an engine or electric motor) into hydraulic pressure.

- **Maintain Flow:** Pumps ensure a continuous supply of hydraulic fluid under pressure to various components in the system.

---

### **2. Hydraulic Reservoir**

The hydraulic reservoir stores the hydraulic fluid used in the system. It acts as a reservoir to hold the fluid that the pump circulates through the system.

#### **Functions:**

- **Fluid Storage:** Keeps a sufficient amount of fluid to maintain system operation.

- **Cooling:** The reservoir helps dissipate heat from the hydraulic fluid, preventing overheating.

- **Contaminant Removal:** Often equipped with filters to trap contaminants and keep the fluid clean.

---

### **3. Hydraulic Actuators (Cylinders and Motors)**

Hydraulic actuators convert hydraulic energy (pressure and flow) into mechanical movement.

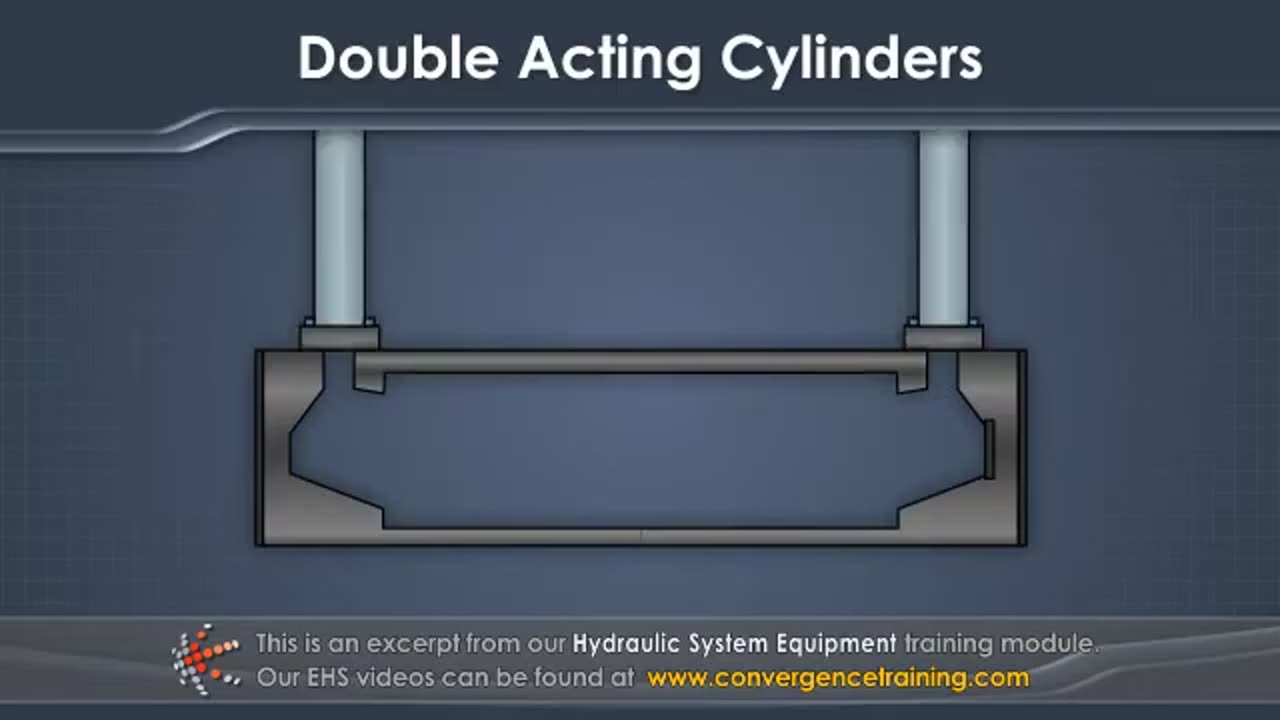

#### **A. Hydraulic Cylinders:**

- **Single-Acting Cylinders:** Use hydraulic pressure to move the piston in one direction (e.g., lifting) and return under a spring or gravity.

- **Double-Acting Cylinders:** Allow movement in both directions (extend and retract) by applying pressure to both sides of the piston.

- **Function:** Used for linear motion in applications like lifting, pushing, or clamping.

#### **B. Hydraulic Motors:**

- **Function:** Hydraulic motors convert hydraulic energy into rotational motion. They are used to drive machinery, conveyors, or rotary equipment.

- **Types:** Gear motors, vane motors, and piston motors, each offering different efficiencies and torque outputs.

---

### **4. Hydraulic Valves**

Valves control the direction, flow, and pressure of hydraulic fluid in the system. They regulate the movement of actuators and maintain the safety and efficiency of the system.

#### **Types of Hydraulic Valves:**

- **Directional Control Valves:** Control the flow of hydraulic fluid to specific parts of the system (e.g., a spool valve that determines the direction of actuator movement).

- **Pressure Relief Valves:** Prevent over-pressurization of the system by redirecting fluid to the reservoir once a preset pressure limit is reached.

- **Flow Control Valves:** Adjust the flow rate to control the speed of actuators.

#### **Functions:**

- **Flow Direction:** Direct hydraulic fluid to the appropriate actuator or component.

- **Pressure Control:** Maintain or limit the pressure within the system to protect components.

- **Speed Control:** Adjust the flow to control the speed of hydraulic actuators.

---

### **5. Hydraulic Hoses and Pipes**

Hydraulic hoses and pipes are used to transfer hydraulic fluid throughout the system.

#### **Types:**

- **Flexible Hoses:** Made of reinforced rubber or synthetic material, used for connecting parts that may experience vibration or movement.

- **Rigid Pipes:** Made from steel or aluminum, used for fixed, stationary connections between components.

#### **Functions:**

- **Fluid Transfer:** Carry hydraulic fluid between the pump, actuators, valves, and other components.

- **Pressure Resistance:** Must withstand high pressure while maintaining flexibility or rigidity as required.

---

### **6. Hydraulic Filters**

Filters ensure the hydraulic fluid remains clean, preventing contamination that can damage components like pumps and valves.

#### **Types:**

- **Suction Filters:** Located at the inlet of the pump to filter the fluid as it enters the pump.

- **Return Filters:** Installed in the return line to remove contaminants as the fluid returns to the reservoir.

- **Pressure Filters:** Positioned to filter fluid under pressure, typically in the supply line to prevent contamination from entering sensitive components.

#### **Functions:**

- **Contaminant Removal:** Filter out dirt, debris, and other contaminants that can impair system performance or damage parts.

- **System Protection:** Protect pumps, valves, and other sensitive components from wear and damage caused by contamination.

---

### **7. Accumulators**

An accumulator stores hydraulic energy in the form of compressed fluid. It helps manage pressure fluctuations and provides additional power during peak demands.

#### **Types:**

- **Bladder Accumulators:** Use a flexible bladder to separate hydraulic fluid from a compressible gas (usually nitrogen) to store energy.

- **Piston Accumulators:** Use a piston to separate the fluid from the gas and store energy.

- **Diaphragm Accumulators:** Similar to bladder accumulators, but with a diaphragm separating the gas and fluid.

#### **Functions:**

- **Energy Storage:** Provides extra fluid during peak pressure conditions.

- **Pressure Stabilization:** Helps maintain constant pressure in the system and smooth out pressure spikes.

- **Emergency Power:** Can provide hydraulic fluid to keep the system operating during a pump failure.

---

### **8. Hydraulic Pressure Gauges**

Pressure gauges measure the pressure of the hydraulic fluid in the system. They are critical for monitoring system health and performance.

#### **Functions:**

- **Pressure Monitoring:** Keep track of the system’s pressure to ensure it operates within the desired range.

- **Safety Alerts:** Alert operators if the pressure exceeds safe levels, preventing damage to components.

---

### **9. Hydraulic Control Panels**

Control panels are used to operate and monitor the hydraulic system. They typically include various buttons, switches, gauges, and indicators to manage the operation of pumps, actuators, and valves.

#### **Functions:**

- **System Control:** Operators use control panels to start, stop, or adjust the operation of hydraulic equipment.

- **Monitoring:** Provide real-time feedback on the system’s status, including pressure, fluid levels, and operational performance.

---

### **Conclusion:**

Hydraulic systems are integral in various industries for their power and precision in lifting, moving, or applying force. Understanding the roles and functions of each piece of hydraulic equipment is crucial for effective system design, operation, and maintenance. These systems rely on components like pumps, actuators, valves, hoses, and filters to function efficiently, safely, and effectively. By maintaining and optimizing these parts, hydraulic systems can deliver reliable performance in applications ranging from construction machinery to aerospace systems.

-

58:14

58:14

theDaily302

18 hours agoThe Daily 302- Tim Ballard

57.1K8 -

13:22

13:22

Stephen Gardner

11 hours ago🔥You'll NEVER Believe what Trump wants NOW!!

106K250 -

54:56

54:56

Digital Social Hour

1 day ago $10.51 earnedDOGE, Deep State, Drones & Charlie Kirk | Donald Trump Jr.

59.2K5 -

DVR

DVR

The Trish Regan Show

13 hours agoTrump‘s FCC Targets Disney CEO Bob Iger Over ABC News Alleged Misconduct

61.7K37 -

1:48:19

1:48:19

The Quartering

14 hours agoElon Calls White People Dumb, Vivek Calls American's Lazy & Why Modern Christmas Movies Suck!

145K112 -

2:08:42

2:08:42

The Dilley Show

14 hours ago $37.01 earnedH1B Visa Debate, Culture and More! w/Author Brenden Dilley 12/26/2024

125K42 -

4:55:59

4:55:59

LumpyPotatoX2

17 hours agoThirsty Thursday on BOX Day - #RumbleGaming

113K7 -

1:04:52

1:04:52

Geeks + Gamers

16 hours agoDisney RATIO'D on Christmas Day | Mufasa Embarrassed By Sonic 3

83.9K11 -

8:27:46

8:27:46

Sm0k3m

20 hours agoRumblers Assemble

53K3 -

10:37

10:37

Russell Brand

2 days agoHow is this even allowed?

208K973