Premium Only Content

Pump Basics

Pumps are mechanical devices used to move liquids, gases, or slurries by converting energy (mechanical, electrical, or hydraulic) into fluid movement. They are essential in various industries, including water supply, oil and gas, chemical processing, and manufacturing. Here's an overview of pump basics:

---

### **1. Types of Pumps**

Pumps are broadly classified based on their working principle:

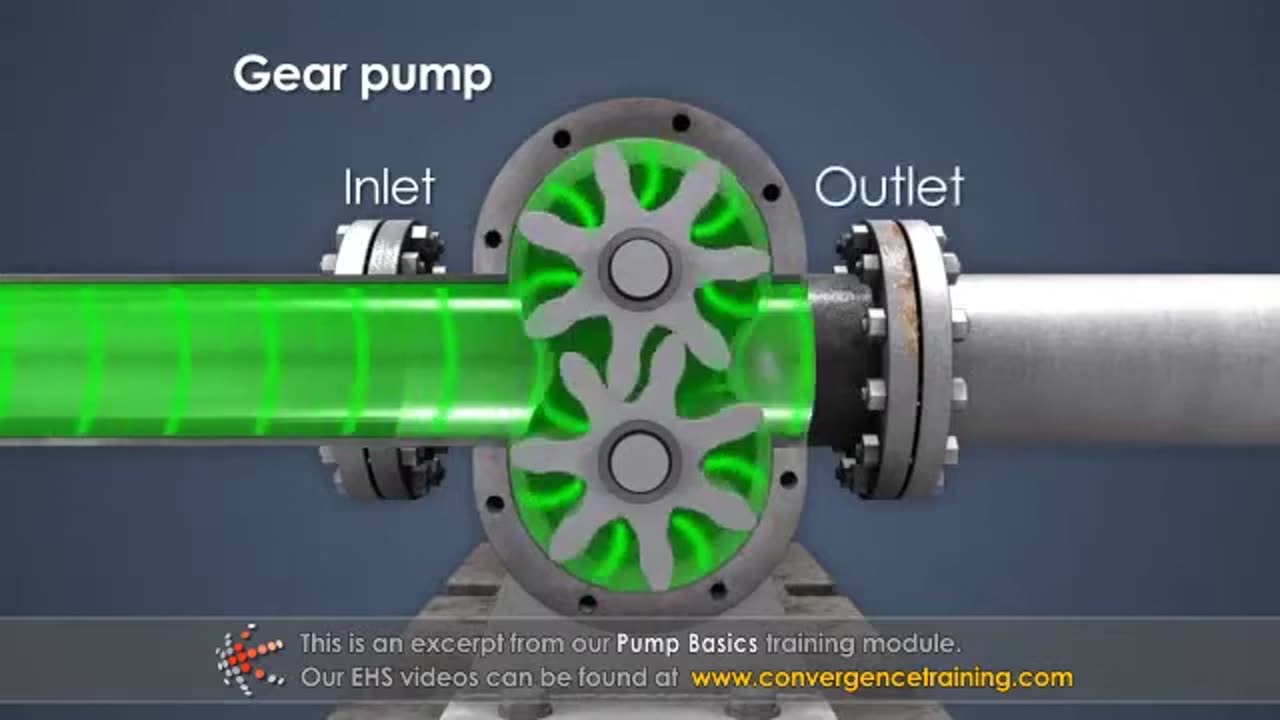

#### **A. Positive Displacement Pumps**

- **How They Work:** Trap a fixed volume of fluid and move it mechanically through the system.

- **Key Characteristics:**

- Deliver a constant flow regardless of pressure changes.

- Suitable for high-viscosity fluids and precise applications.

- **Examples:**

- Gear Pump

- Diaphragm Pump

- Peristaltic Pump

- Screw Pump

#### **B. Centrifugal Pumps**

- **How They Work:** Use rotational energy from an impeller to move fluid by creating velocity, which is converted to pressure.

- **Key Characteristics:**

- Best for low-viscosity fluids.

- Efficiency depends on flow and pressure conditions.

- **Examples:**

- End-Suction Pump

- Vertical Pump

- Submersible Pump

- Multistage Pump

---

### **2. Key Pump Components**

1. **Impeller (Centrifugal Pumps):** Rotating component that imparts kinetic energy to the fluid.

2. **Casing:** Encloses the pump and directs fluid flow.

3. **Inlet (Suction Side):** Entry point for the fluid.

4. **Outlet (Discharge Side):** Exit point for the fluid.

5. **Seal/Stuffing Box:** Prevents leaks where the shaft exits the casing.

6. **Motor/Driver:** Provides energy to operate the pump.

---

### **3. Pump Terminology**

1. **Flow Rate (Q):** Volume of fluid moved per unit of time, typically measured in liters per second (L/s) or gallons per minute (GPM).

2. **Head (H):** The height to which a pump can raise fluid, measured in meters or feet.

3. **Pressure:** Force exerted by the fluid, often related to the head.

4. **Efficiency:** Ratio of output power to input power, expressed as a percentage.

5. **Net Positive Suction Head (NPSH):** Ensures there’s enough pressure to avoid cavitation at the pump’s suction.

---

### **4. Common Pump Applications**

- **Centrifugal Pumps:** Water supply, irrigation, HVAC systems.

- **Diaphragm Pumps:** Chemical dosing, wastewater treatment.

- **Gear Pumps:** Lubrication systems, oil transfer.

- **Peristaltic Pumps:** Medical devices, food processing.

---

### **5. Pump Operation**

- **Priming:** Some pumps (like centrifugal) need priming to fill the suction line and pump casing with fluid.

- **Direction of Rotation:** Ensure correct motor/pump alignment and rotation.

- **Flow Regulation:** Adjust flow rate using valves or variable speed drives (VSDs).

---

### **6. Pump Maintenance**

- **Inspection:** Regularly check seals, bearings, and impellers for wear or damage.

- **Lubrication:** Keep moving parts properly lubricated.

- **Alignment:** Ensure shaft and motor are aligned to prevent excessive wear.

- **Cleaning:** Remove debris from the casing and suction lines.

---

### **7. Pump Safety Tips**

- Never run a pump dry unless designed for such operation.

- Use appropriate PPE when handling hazardous fluids.

- Monitor for unusual noises or vibrations that may indicate mechanical issues.

- Follow manufacturer’s guidelines for installation and operation.

Understanding pump basics helps in selecting, operating, and maintaining pumps efficiently and safely across various applications.

-

6:43

6:43

HSESafetyInformation

1 month agoLahori Chanay Recipe - Lahori Cholay Recipe - Chana Chana Masala

34 -

LIVE

LIVE

Mally_Mouse

33 minutes agoLet's Hang!! - Just Chillin' & Chattin

175 watching -

1:31:49

1:31:49

Kim Iversen

5 hours agoCIA Fingerprints All Over JFK’s Assassination: Dirty Secrets & Shocking Israeli Connections??

75.3K72 -

2:03:50

2:03:50

vivafrei

8 hours agoElon CONFIRMS Biden Played Politics with Astronauts; JFK Files Dud? Trump Attacks Poilievre & MORE!

148K119 -

LIVE

LIVE

Dr Disrespect

8 hours ago🔴LIVE - DR DISRESPECT - WARZONE - 10 WINS IN A ROW EVENT

1,963 watching -

44:20

44:20

Candace Show Podcast

4 hours agoRyan Reynolds Wants to COME OUT… Of The Lawsuit | Candace Ep 163

86.1K53 -

LIVE

LIVE

LFA TV

1 day agoEurope: ‘To Avoid War, We Must Get Ready for War’ | TRUMPET DAILY 3.19.25 7PM

357 watching -

LIVE

LIVE

2 MIKES LIVE

3 hours ago2 MIKES LIVE #194 News Breakdown Wednesday!

144 watching -

10:05

10:05

Tundra Tactical

2 hours agoPam Bondi MISSES 2A Report Deadline!

5.91K3 -

21:52

21:52

AlaskanBallistics

17 hours ago $0.05 earnedFederal Terminal Ascent vs. Hornady ELD-X 6.5 Creedmoor

4.01K1