Premium Only Content

SAFETY SHOWERS AND EYE WASHES

**Safety Showers and Eye Wash Stations** are essential emergency equipment in workplaces where hazardous chemicals or substances are used. They provide immediate first aid to workers exposed to harmful materials, minimizing injury until professional medical care is available.

---

### **Purpose of Safety Showers and Eye Wash Stations**

- To quickly rinse off hazardous chemicals or contaminants from the body and eyes.

- To prevent or minimize chemical burns, irritation, or absorption.

- To flush out particles or debris that may cause eye injuries.

---

### **Key Features and Requirements** (ANSI Z358.1 Standard)

1. **Location**

- Must be within 10 seconds' travel distance (approximately 55 feet) from potential hazards.

- Should be on the same level as the hazard, with a clear and unobstructed path.

2. **Activation**

- Equipment must activate in 1 second or less.

- Operable with a single motion and hands-free once activated.

3. **Water Flow**

- **Eye Wash Stations**: Deliver a gentle flow of water to both eyes simultaneously at 0.4 gallons per minute for 15 minutes.

- **Safety Showers**: Provide a flow of at least 20 gallons per minute for 15 minutes.

4. **Temperature**

- Water should be tepid, typically between 60°F and 100°F (15.5°C–37.8°C).

5. **Maintenance**

- Weekly activation to check functionality and flush stagnant water.

- Annual inspection to ensure compliance with performance standards.

6. **Signage and Visibility**

- Clearly marked with highly visible signs.

- Areas should be well-lit and easily identifiable.

---

### **Types of Equipment**

1. **Eye Wash Stations**

- **Plumbed**: Permanently connected to a water supply.

- **Portable**: For locations without water lines; includes self-contained units.

2. **Safety Showers**

- Overhead showers for full-body rinsing.

3. **Combination Units**

- Integrated systems with both shower and eye wash capabilities.

4. **Specialized Equipment**

- Personal eye wash bottles for immediate use (not a substitute for standard stations).

- Drench hoses for localized rinsing.

---

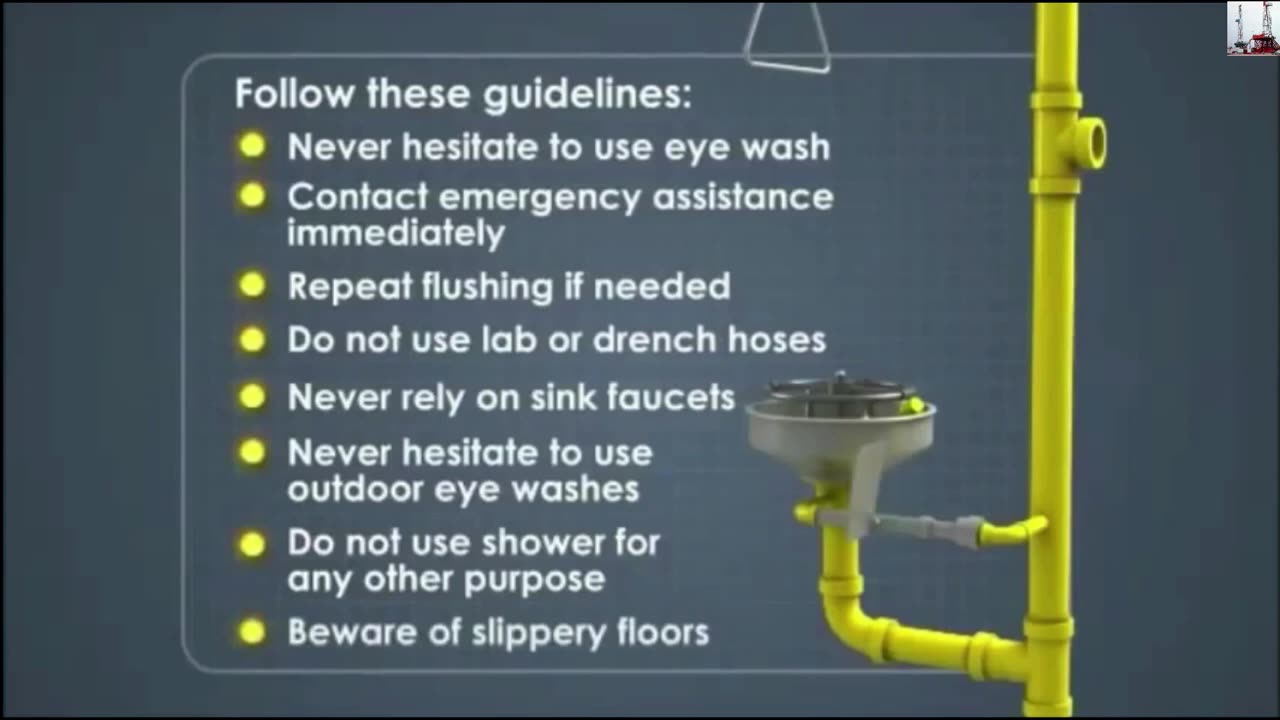

### **Best Practices for Use**

1. **Immediate Action**

- Access the station immediately after exposure.

- Keep eyes open during rinsing and roll them to flush thoroughly.

2. **Duration**

- Use for at least 15 minutes or as directed by safety guidelines.

- Remove contaminated clothing while using a safety shower.

3. **Training**

- Employees must know the location and proper use of the equipment.

- Conduct regular safety drills.

---

### **Common Applications**

- Laboratories, chemical plants, and manufacturing facilities.

- Workplaces handling corrosive, toxic, or reactive chemicals.

- Environments with potential exposure to particulates or biological hazards.

Would you like a detailed checklist for installing or maintaining safety showers and eye wash stations?

-

1:25:53

1:25:53

Kim Iversen

3 days agoStriking Back: Taking on the ADL’s Anti-Free Speech Agenda

74K37 -

49:35

49:35

Donald Trump Jr.

12 hours agoA New Golden Age: Countdown to Inauguration Day | TRIGGERED Ep.202

154K173 -

1:14:34

1:14:34

Michael Franzese

11 hours agoWhat's Behind Biden's Shocking Death Row Pardons?

68.7K43 -

9:49

9:49

Tundra Tactical

10 hours ago $15.74 earnedThe Best Tundra Clips from 2024 Part 1.

88.6K7 -

1:05:19

1:05:19

Sarah Westall

10 hours agoDying to Be Thin: Ozempic & Obesity, Shedding Massive Weight Safely Using GLP-1 Receptors, Dr. Kazer

78.5K21 -

54:38

54:38

LFA TV

1 day agoThe Resistance Is Gone | Trumpet Daily 12.26.24 7PM EST

57.3K11 -

58:14

58:14

theDaily302

19 hours agoThe Daily 302- Tim Ballard

57.1K9 -

13:22

13:22

Stephen Gardner

12 hours ago🔥You'll NEVER Believe what Trump wants NOW!!

106K297 -

54:56

54:56

Digital Social Hour

1 day ago $10.83 earnedDOGE, Deep State, Drones & Charlie Kirk | Donald Trump Jr.

59.2K5 -

DVR

DVR

The Trish Regan Show

14 hours agoTrump‘s FCC Targets Disney CEO Bob Iger Over ABC News Alleged Misconduct

64.2K39