Premium Only Content

Working at Height Training

**Working at Height Training** is designed to ensure the safety of workers performing tasks above ground level. This type of training is essential to minimize the risks of falls, injuries, and fatalities. Below is an overview of what such training typically includes:

---

### **1. Understanding Work at Height**

- **Definition**: Work at height refers to any activity where a person could fall a distance liable to cause injury, including working on ladders, scaffolding, rooftops, or elevated platforms.

- **Key Risks**:

- Falls from ladders or platforms.

- Dropped tools or equipment.

- Structural failures of working surfaces.

---

### **2. Legal and Regulatory Framework**

- Overview of local laws and industry standards.

- Employer and employee responsibilities.

- Importance of risk assessments before beginning tasks.

---

### **3. Risk Assessment**

- **Identifying Hazards**:

- Unstable or poorly maintained surfaces.

- Weather conditions (e.g., wind, rain).

- Poor lighting or visibility.

- **Evaluating Risks**:

- Probability of a fall.

- Severity of potential injuries.

- **Control Measures**:

- Eliminate the need to work at height where possible.

- Use safer equipment or methods.

---

### **4. Equipment Safety**

- **Types of Equipment**:

- Ladders, scaffolds, mobile elevated work platforms (MEWPs).

- Personal protective equipment (PPE) like harnesses, helmets, and safety boots.

- **Inspection and Maintenance**:

- Regularly check for damage or wear.

- Ensure proper storage and handling.

- **Safe Use**:

- Follow manufacturer guidelines.

- Avoid overloading equipment.

---

### **5. Fall Protection Systems**

- **Types**:

- Guardrails and toe boards.

- Safety nets and catch platforms.

- Fall arrest systems (e.g., lifelines, harnesses).

- **Training in Use**:

- Correctly fitting harnesses.

- Anchoring and attaching lifelines.

- Emergency procedures in case of a fall.

---

### **6. Ladder Safety**

- Selecting the right type of ladder for the task.

- Checking ladder stability and condition.

- Maintaining three points of contact while climbing.

- Avoiding overreaching or leaning.

---

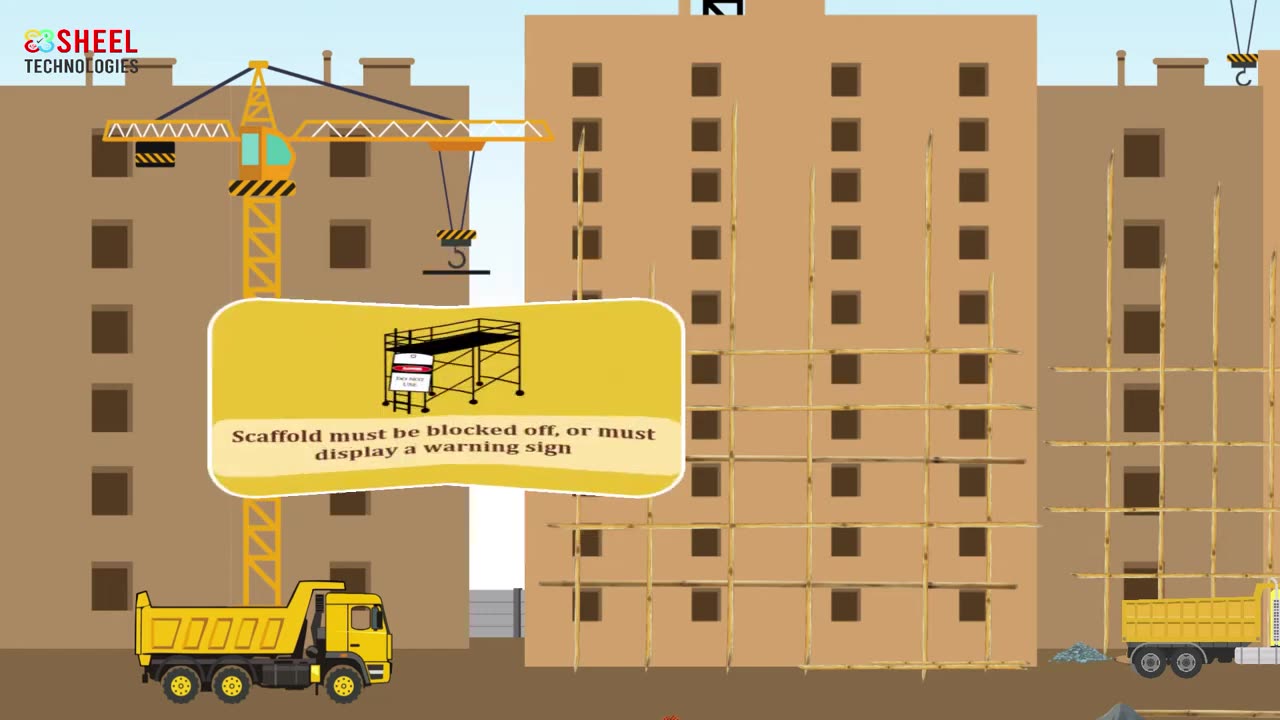

### **7. Scaffolding Safety**

- **Setup and Inspection**:

- Assembling scaffolds according to safety standards.

- Inspecting scaffolding before and during use.

- **Safe Practices**:

- Avoiding overloading scaffolding.

- Using access ladders and guardrails.

---

### **8. Safe Work Practices**

- Planning tasks to minimize time spent at height.

- Keeping tools and equipment secured.

- Avoiding work in adverse weather conditions.

- Ensuring clear communication among team members.

---

### **9. Emergency Preparedness**

- Preparing rescue plans for fall incidents.

- Using fall arrest systems to minimize injury.

- Training workers in first aid and emergency response.

---

### **10. Practical Training and Drills**

- Hands-on exercises with safety equipment.

- Simulated work-at-height scenarios.

- Demonstrations of proper and improper practices.

---

### **11. Key Behavioral Safety Principles**

- Encouraging workers to speak up about unsafe conditions.

- Promoting a culture of safety and accountability.

- Regularly updating training to reflect new risks and technologies.

---

**Conclusion**:

Working at Height Training not only fulfills legal requirements but also ensures the safety and confidence of workers. It reduces workplace injuries and promotes efficient, secure operations in elevated environments.

Would you like more detailed guidance, or help tailoring a training program for your team?

-

20:24

20:24

HSESafetyInformation

2 months agoKABULI PULAO RECIPE - Original 40+ KG Afghani Meat Pulau Prepared - Street Food Qabili Plav Recipe_2

27 -

13:05

13:05

Cowboy Kent Rollins

1 day ago $12.44 earnedHomemade Cowboy Corn Dogs | Easy Corndog Recipe

58.5K27 -

6:26:31

6:26:31

GritsGG

7 hours ago#1 Warzone Win Grind! 🔥

28.5K6 -

8:24

8:24

Talk Nerdy Sports - The Ultimate Sports Betting Podcast

7 hours ago4/26/25 - Saturday Annihilation: Vasil’s 8 Sharp Picks and 2 PrizePicks Built for Blood 💥📈

61.5K4 -

LIVE

LIVE

GamingWithHemp

6 hours agoElder Scrolls Oblivion Remastered Episode #2 Ultra high settings

86 watching -

23:52

23:52

The Rad Factory

9 hours ago $2.10 earnedIs My Formula Race Car Faster Than a Go Kart?

39.7K3 -

20:56

20:56

marcushouse

9 hours ago $2.33 earnedStarship Flight Test 9 Vehicles FINALLY Prepare, and Huge Starbase Upgrades – It's All Happening!

39.1K17 -

23:48

23:48

CatfishedOnline

23 hours agoVictim's Life is Threatened After He Gets in Too Deep With a Crypto Scammer

36.4K6 -

8:40

8:40

Shea Whitney

10 hours ago $2.02 earned12 Fashion Mistakes Making You Look OLD & OUTDATED!

29.5K11 -

29:18

29:18

TampaAerialMedia

11 hours ago $0.82 earnedUpdate SARASOTA, FL 2025 - St Armands, Lido, & Longboat Key

19.6K2