Premium Only Content

Lock Out Tag Out Training

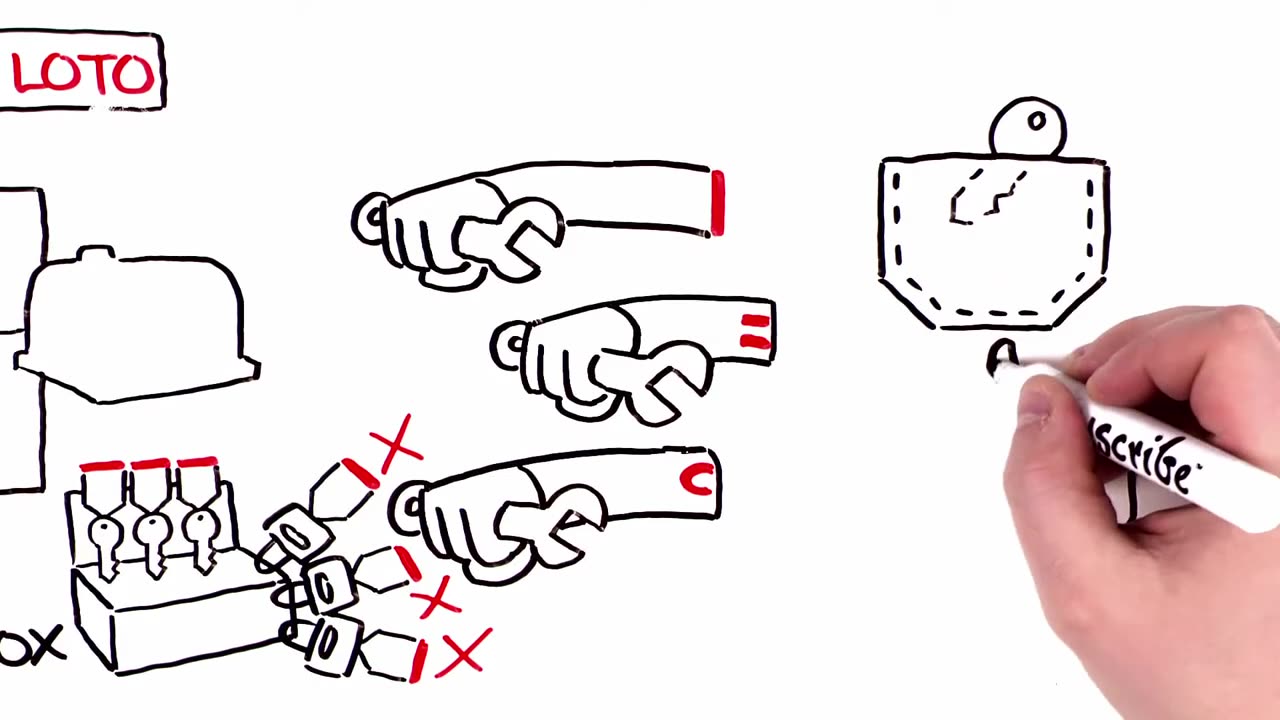

### **Lockout/Tagout (LOTO) Training Guide**

Lockout/Tagout (LOTO) training is designed to educate employees on the proper procedures for controlling hazardous energy, ensuring workplace safety during equipment maintenance and servicing. Effective LOTO training is essential to prevent accidents, injuries, and fatalities caused by the unexpected release of energy.

---

### **1. Objectives of LOTO Training**

By the end of LOTO training, participants should:

- Understand the purpose and importance of LOTO procedures.

- Identify hazardous energy sources.

- Know how to perform LOTO safely.

- Comply with regulatory standards (e.g., OSHA 29 CFR 1910.147).

---

### **2. Who Needs LOTO Training?**

1. **Authorized Employees**

- Perform LOTO procedures (e.g., maintenance and service personnel).

2. **Affected Employees**

- Work in areas where LOTO procedures are being implemented but do not perform the lockout themselves.

3. **Other Employees**

- All other staff who may encounter LOTO activities in the workplace.

---

### **3. Key Components of LOTO Training**

#### **A. Understanding Hazardous Energy**

- Types of hazardous energy:

- Electrical, mechanical, hydraulic, pneumatic, thermal, chemical, and stored energy.

- Potential risks associated with uncontrolled energy release.

#### **B. LOTO Devices**

- Locks

- Tags

- Valve lockouts, circuit breaker lockouts, and other isolation devices.

#### **C. The LOTO Procedure**

1. **Preparation**:

- Identify all energy sources.

- Notify affected personnel.

2. **Shutdown**:

- Turn off the equipment following standard procedures.

3. **Isolation**:

- Disconnect energy sources using switches, valves, or circuit breakers.

4. **Lockout/Tagout Application**:

- Apply locks and tags to isolation points.

5. **Release of Stored Energy**:

- Safely release residual or stored energy.

6. **Verification**:

- Test the equipment to ensure no energy remains.

7. **Maintenance/Servicing**:

- Perform the work while ensuring safety.

8. **Restoration**:

- Inspect the area, remove locks/tags, notify personnel, and restore energy.

#### **D. Safe and Unsafe Practices**

- Safe: Always apply personal locks, verify isolation, and follow all steps.

- Unsafe: Skipping steps, relying on shared locks, or failing to test for residual energy.

#### **E. Emergency Procedures**

- What to do if a lock or tag must be removed in an emergency.

- Procedures for responding to unexpected energy releases.

---

### **4. Hands-On Training**

Participants should practice:

- Identifying hazardous energy sources.

- Applying locks and tags to energy-isolation points.

- Verifying equipment is de-energized.

- Following proper removal and restoration procedures.

---

### **5. Training Frequency**

- Initial training for new employees or when new equipment/procedures are introduced.

- Refresher training annually or when audits identify deficiencies.

---

### **6. Assessment and Certification**

- Conduct a written or practical test to assess understanding.

- Provide a certification of completion for authorized employees.

---

### **7. Regulatory Compliance**

- Training programs must comply with industry and legal standards, such as OSHA or other local regulations.

---

### **8. Creating a Safety Culture**

- Reinforce that LOTO is non-negotiable.

- Encourage employees to report unsafe practices and suggest improvements.

---

By combining theoretical knowledge with practical exercises, LOTO training ensures that employees are prepared to control hazardous energy effectively, safeguarding themselves and others in the workplace.

-

1:35

1:35

HSESafetyInformation

1 month agoMutton Chops two ways- baked & grilled Recipe by Food Fusion (Eid Recipe)

57 -

1:41:45

1:41:45

The Connect: With Johnny Mitchell

15 hours ago $14.35 earnedMexican Cartels Are Moving MORE Drugs Than Ever, Going To WAR On The Government (Emergency Update)

42.8K5 -

6:54:01

6:54:01

MissesMaam

11 hours agoFinishin' Red Dead Redemption 💚✨

67.1K7 -

34:44

34:44

LFA TV

5 days agoMIRACLES DO HAPPEN!

80K1 -

5:26:31

5:26:31

GamersErr0r

6 hours ago $3.47 earnedMooning My Community

36.4K -

2:22:59

2:22:59

Banks Atkin Live

9 hours agoChilling playing Games & Vibin

62.9K1 -

8:08:50

8:08:50

Dragoon_B

10 hours agoNothing crazy - just Counter Strike + Valorant

26.4K1 -

18:03

18:03

Stephen Gardner

10 hours ago🔥YES!! Trump GETS HUGE win in 4th district court!!

74.3K395 -

4:40:54

4:40:54

G3T

8 hours ago🔴GET | not saying it

22.4K -

15:35

15:35

DeVory Darkins

15 hours ago $4.99 earnedGavin Newsom drops CRUSHING BLOW on Democrats

26.5K70