Premium Only Content

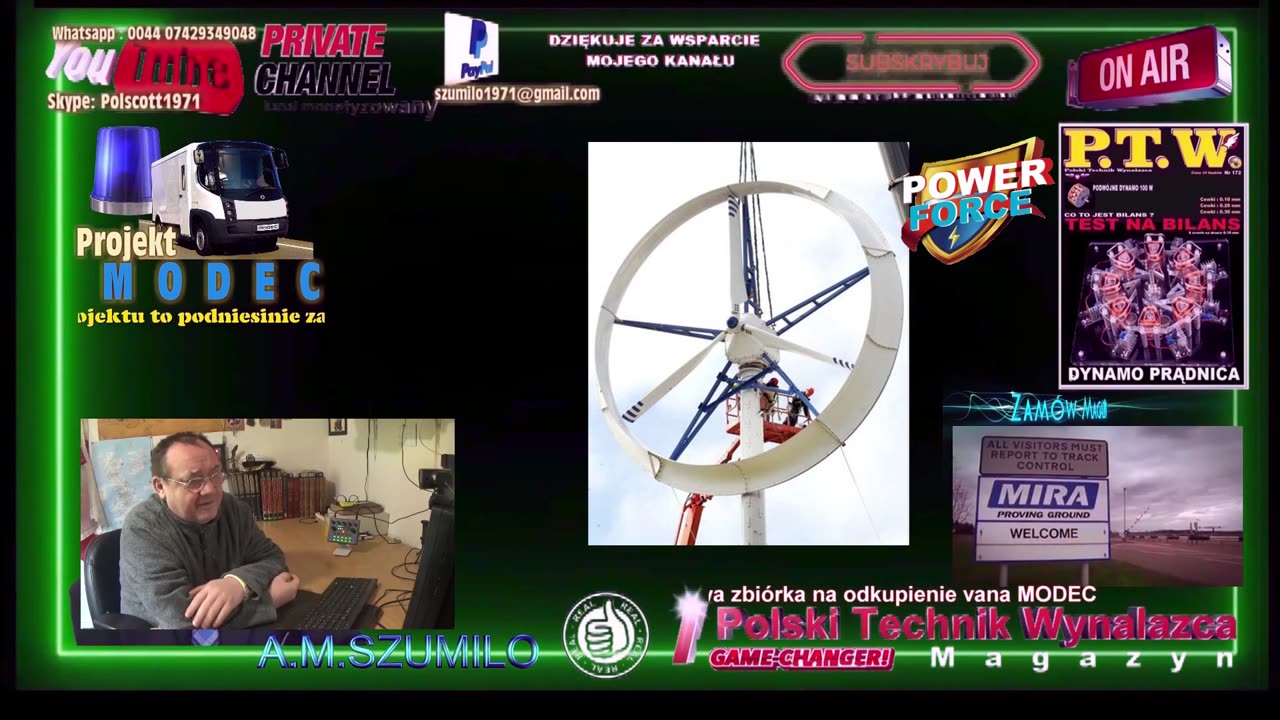

Advanced wind turbines, dubbed the Wind Sphere, now made in Northeast Ohio

Dubbed the Wind Sphere, it is capable of generating about 30 percent more power than other turbines of the same size. The Wind Sphere began as an idea in the mind of Mark Cironi, president of Green Energy Technologies, which today is a subsidiary of ParkOhio.

"The system was designed, tested and is currently being manufactured in northern Ohio," said Cironi. "As the only OEM wind turbine manufacturer in Ohio we are now moving into commercialization."

The actual manufacturing of the machine is being handled by ParkOhio's Ajax TOCCO Magnethermic, which manufacturers most of the components and assembles the turbine in a plant in Warren.

"We like renewable energy. We think it's the future, and we think it's important that we get our company into this space," said Edward Crawford, CEO of ParkOhio, which is a global company with 6,000 employees.

"We have been developing this for four or five years. We have invested a substantial amount of capital.

"We want to be able to put these on top of buildings and in the future we expect to downsize and make them available for homes," he said.

The company this week commissioned a Wind Sphere turbine in a grassy area adjacent to the parking lot of an Ajax facility on Lakeland Boulevard in Wickliffe, less than a mile east of the two turbines at William Sopko and Son Company on Lakeland and about 4 miles due east of the giant Lincoln Electric turbine in Euclid.

Last November, the company installed a Wind Sphere on the campus of Youngstown State University. More orders are pending, said Cironi.What enables this machine to outperform the competition is a carefully engineered fiberglass shroud that surrounds the turbine blade, extending slightly forward as well to the rear of the turbine.The shroud's smoothly curved surfaces at the front of the turbine draw more air toward the spinning blade and help prevent the air from losing velocity.

Behind the turbine blade, the shroud helps the "spent" air to quickly escape without creating eddies that could slow down the incoming air.

"The surfaces are very smooth. You are trying to shape the airflow through the rotor [blade]. Essentially, you are gathering extra wind," explained David Spera, a retired NASA engineer who helped develop the initial versions of the shroud.

Spera said the curvature of the shroud is based on the curvature of an airplane wing, and relies on the same physics used to create lift in an aircraft.

Here are the turbine specifications:

Blade diameter: 28.5 feet

Shroud diameter: 37.5 feet

Nameplate generating capability of 25 kilowatts (25,000 watts)

Mounting pole height: 93 feet

Height as measured from the top of the shroud: 105 feet

Capable of generating 70,000 to 80,000 kilowatt-hours per year in Greater Cleveland, given the wind characteristics here. As a point of comparison, the average consumer uses 750 to 1,000 kilowatt-hours a month. The company recommends posting a wind gauge for 90 to 120 days before choosing a location.

Total cost of a Wind Sphere, including installation will range from $300,000 to $350,000.

-

1:01:03

1:01:03

The Rubin Report

2 hours agoTech Legend Gives the Real Odds of Elon Musk Successfully Cutting Gov’t | Joe Lonsdale

12.2K2 -

UPCOMING

UPCOMING

The Shannon Joy Show

3 hours ago🔥🔥Chip Roy's Fabulous Christmas Shutdown - Mr. Scrooge Or Miracle On K-Street? 🔥🔥

395 -

53:31

53:31

Dave Portnoy

3 hours agoThe Unnamed Show With Dave Portnoy, Kirk Minihane, Ryan Whitney - Episode 40

31K1 -

LIVE

LIVE

Tudor Dixon

28 minutes agoCorruption and Influence: The Biden Family Saga | The Tudor Dixon Podcast

249 watching -

LIVE

LIVE

The Big Mig™

14 hours agoGlobal Finance Forum Powered By Genesis Gold Group

1,153 watching -

2:45:29

2:45:29

Matt Kohrs

14 hours agoMarket Crash, Breaking Inflation News & Payday Friday || The MK Show

39.1K5 -

LIVE

LIVE

LFA TV

14 hours agoWHAT IS HAPPENING IN DC?? | LIVE FROM AMERICA 12.20.24 11am EST

5,503 watching -

LIVE

LIVE

Caleb Hammer

2 hours agoDelusional Lady Destroys Life To Hurt Her Ex | Financial Audit

195 watching -

49:01

49:01

BonginoReport

5 hours agoThe Final Countdown to Shutdown (Ep.109) - 12/20/2024

77.8K181 -

2:59:05

2:59:05

Wendy Bell Radio

7 hours agoCongress Plays Shutdown Chicken

59.6K98