Premium Only Content

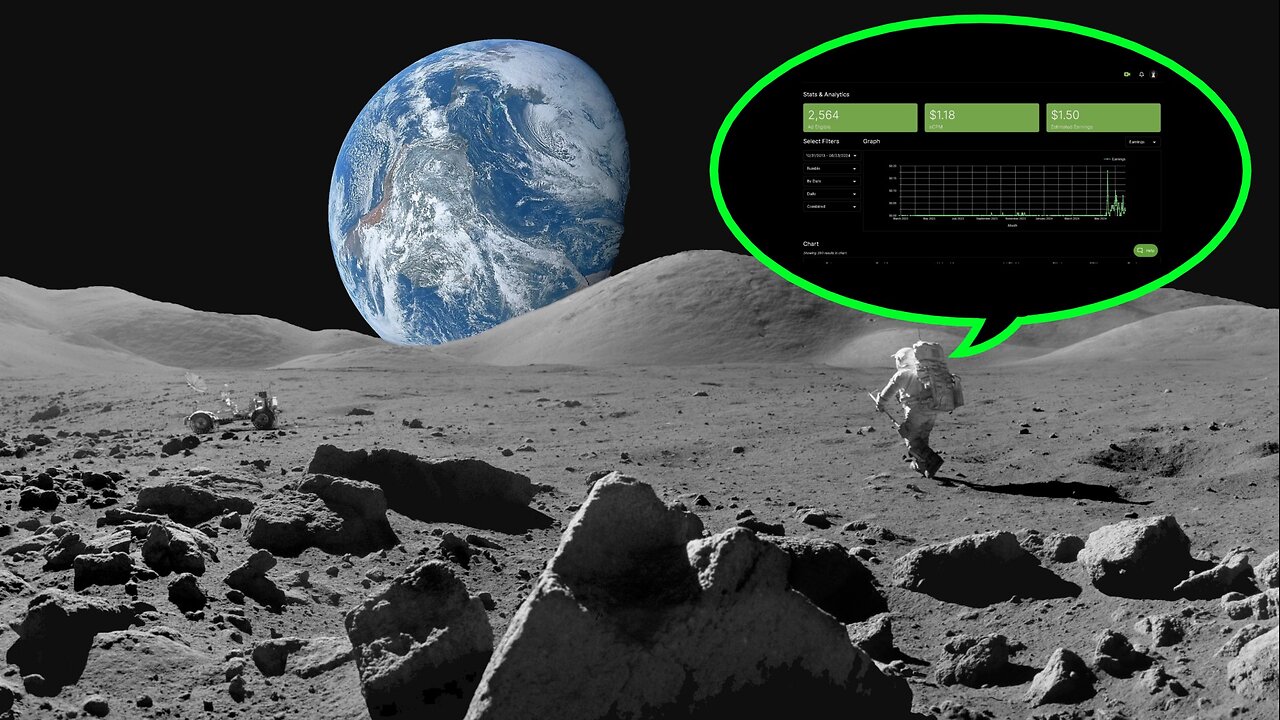

YOU Can Help Fund a Private Robotic MOON Mission Simply By Watching Our RUMBLE Videos! 🌙

Please Support The RUMBLE Channel

50% of all support (after fees & tax) will go to a private Moon mission

RUMBLE Has More Videos & YOUR VIEWS Help Raise Money For a MOON Mission!

https://rumble.com/user/WhatsNextVids

Patreon:

https://www.patreon.com/user?u=37594401

Buy Me A Coffee?:

https://www.buymeacoffee.com/whats.next

Donate With Cash App:

https://cash.app/$YTpayments

Total Updated Weekly on X/Twitter:

https://x.com/WhatsNe75388303

Establishing a robotic factory on the moon to create rovers and solar panels from regolith, the lunar soil, is an exciting concept that could revolutionize space exploration. The primary challenge lies in developing the necessary technologies to process and transform the unique properties of regolith into functional components for rovers and solar panels. This answer will discuss the steps and processes involved in creating rovers and solar panels using lunar regolith.Properties of RegolithRegolith is a fine-grained material consisting of small rock particles and glass created by meteorite impacts. It covers the lunar surface at an average depth of 4-5 meters. Lunar regolith has several unique properties that make it suitable for manufacturing purposes: Abundance: The abundance of regolith on the moon’s surface makes it an attractive resource for manufacturing. Chemical Composition: Regolith contains essential elements like silicon, oxygen, iron, calcium, and aluminum, which are crucial for creating various materials. Mechanical Properties: Regolith can be easily crushed, melted, or sintered (a process similar to sintering metals) at relatively low temperatures, making it ideal for shaping components.Manufacturing Rovers from RegolithA lunar rover primarily consists of a chassis, wheels/tracks, a power source, and electronic systems. Below is a breakdown of how regolith could be used to manufacture each component:ChassisThe chassis can be constructed by sintering or 3D printing regolith particles into a solid structure. Sintering involves heating the material below its melting point until particles bond together, while 3D printing deposits layers of material to build a part according to a digital design. Both methods can create lightweight yet robust structures using regolith as raw material.Wheels/TracksFor wheeled rovers, inflatable tires made from composite materials or metal-based wheels can be used. In the case of inflatable tires, they can be manufactured using polymers impregnated with regolith dust during production. Metal-based wheels can be cast using lunar-derived metals extracted from the regolith through various chemical processes such as smelting or electrolysis. For tracked rovers, tracks can be made from sintered or 3D printed regolith segments that interlock with one another.Power Source & Electronic SystemsThe power source could be a radioisotope thermoelectric generator (RTG), solar panels, or a combination of both. Solar panels will be discussed in detail in the next section. RTGs use heat generated by radioactive decay to produce electricity; however, constructing an RTG on the moon would require importing radioactive materials due to their scarcity in lunar regolith. Consequently, this section will focus on solar panels as a viable alternative for power generation in rovers produced on the moon utilizing local resources. Electronic systems consist of computers, sensors, communication devices, and actuators that control the rover’s functions; these components would need to be imported from Earth initially but could be replicated on the moon as technology advances through additive manufacturing (3D printing) techniques using imported materials or those derived from lunar resources in future missions.Manufacturing Solar Panels from RegolithSilicon-based solar cells are widely used for space applications due to their high efficiency and stability under extreme conditions; thus, they are an ideal choice for lunar-manufactured solar panels. Silicon can be extracted from lunar regolith through chemical processes like carbothermic reduction or chlorination: 1) Carbothermic reduction involves heating silicon dioxide (SiO2) present in lunar regolith with carbon at high temperatures (1700°C - 1900°C) to produce pure silicon: SiO2 + C → Si + CO2 2) Chlorination utilizes chlorine gas (Cl2) to react with silicon dioxide at lower temperatures (900°C - 1100°C) forming gaseous silicon tetrachloride (SiCl4), which can then be reduced back into pure silicon using hydrogen gas (H2): SiO2 + Cl2 → SiCl4 + O2 ; SiCl4 + H2 → Si + 2HCl After purification and crystallization steps such as zone refining or Czochralski growth methodologies well established in terrestrial production processes, high-quality silicon wafers can be produced for photovoltaic cell fabrication on the moon itself – eliminating transportation costs associated with delivering solar panel components from Earth while reducing overall mission mass significantly .

-

DVR

DVR

Geeks + Gamers

1 hour agoSonic 3 DESTROYS Mufasa And Disney, Naughty Dog Actress SLAMS Gamers Over Intergalactic

8091 -

51:59

51:59

The Dan Bongino Show

2 hours agoDemocrat Donor Admits The Scary Truth (Ep. 2393) - 12/23/2024

177K568 -

2:32:15

2:32:15

Matt Kohrs

13 hours agoRumble CEO Chris Pavlovski Talks $775M Tether Partnership || The MK Show

60K15 -

28:23

28:23

Dave Portnoy

13 hours agoDavey Day Trader Presented by Kraken - December 23, 2024

78.4K29 -

59:29

59:29

BonginoReport

4 hours agoTrump, Murder Plots, and the Christmas Miracle: Evita + Jack Posobiec (Ep.110) - 12/23/2024

70.5K63 -

2:59:14

2:59:14

Wendy Bell Radio

7 hours agoNothing To See Here

65.2K41 -

2:12:18

2:12:18

TheDozenPodcast

23 hours agoIslam vs Christianity: Bob of Speakers' Corner

66.2K16 -

14:36

14:36

The StoneZONE with Roger Stone

1 day agoRoger Stone Delivers Riveting Speech at Turning Point’s AMFEST 2024 | FULL SPEECH

94.4K24 -

18:59

18:59

Fit'n Fire

13 hours ago $5.89 earnedZenith ZF5 The Best MP5 Clone available

50.8K1 -

58:34

58:34

Rethinking the Dollar

22 hours agoTrump Faces 'Big Mess' Ahead | RTD News Update

40.8K5