Premium Only Content

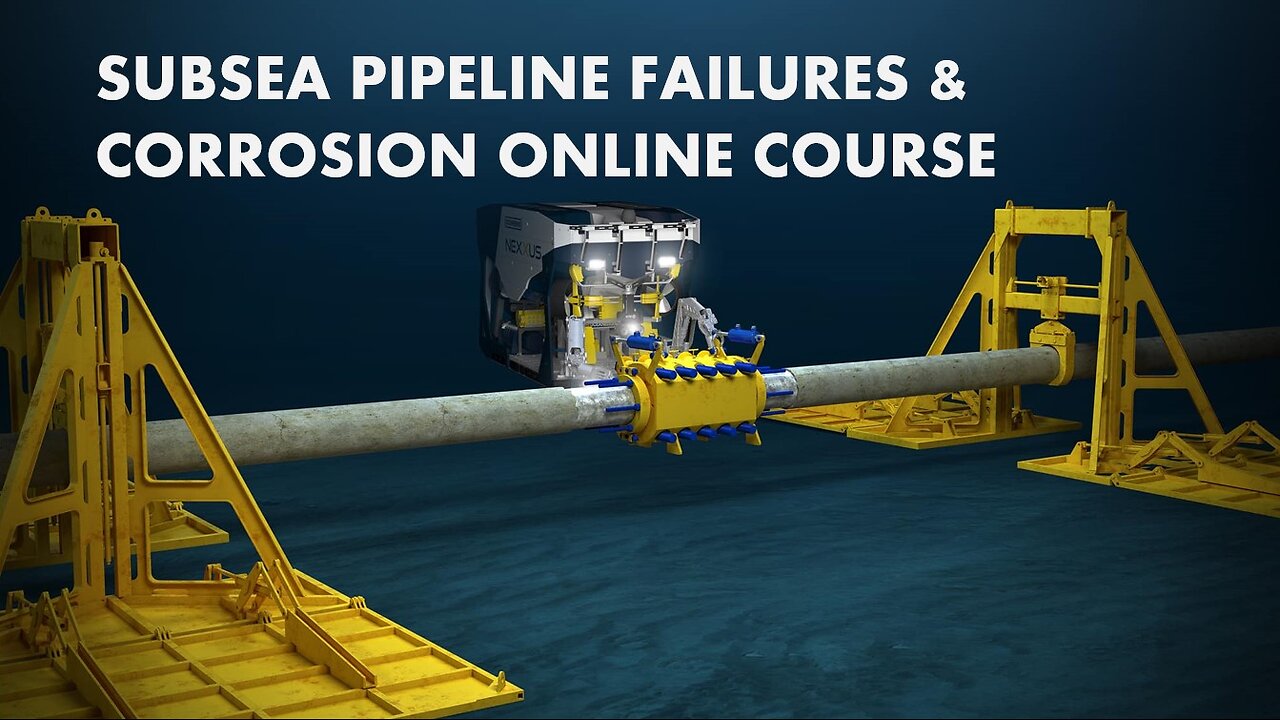

Subsea Pipeline Failures & Corrosion Online Course

Pipelines are an essential part of the oil and gas industry as they are the main means of transportation. As the offshore technology advances, subsea pipelines are being operated in more demanding environments. For the pipelines to operate efficiently, they have to be carefully designed. One of the main threats to the integrity of the pipeline is corrosion, which has caused many failures. Corrosion in subsea pipelines has different forms and understanding their mechanisms is an important step in inhibiting them and decreasing their rate of occurrence. As corrosion is unavoidable, it is beneficial to be able to calculate the corrosion rate and the corrosion allowance. By obtaining the results of the corrosion rate it becomes clearer which type of group of steel to consider for the fabrication of the pipeline.

Subsea engineers battle harsh, corroding marine environments, as well as corrosive fluids that flow inside the pipeline, leaving pipelines extremely susceptible to damage. There are also many variables to consider when dissecting pipeline systems, such as differing installation processes, diameter and thickness of a pipeline, aging in hardware and materials failure. For instance, rigid pipelines are often made of carbon steel and are stiff and hard to install. In contrast, flexible pipelines are relatively easier and cheaper to install but difficult to maintain.

For full videos you can visit this link :

https://drive.google.com/file/d/1mXXnA0XA6S45RbohHPhX3G1OPORLt8X3/view?usp=sharing

and you will be directed to a google drive link where you can download all files of this course

https://drive.google.com/file/d/1y6FaD0mpj9wjR0md6sj9WcK543kGKIUR/view?usp=drive_link

-

8:38:13

8:38:13

Dr Disrespect

19 hours ago🔴LIVE - DR DISRESPECT - MARVEL RIVALS - I AM GROOT

315K62 -

5:58:38

5:58:38

Fresh and Fit

11 hours agoResponding To Druski Skit, Tate Case Win, Fuentes Assassination Attempt & MORE

208K43 -

4:13:32

4:13:32

Nerdrotic

15 hours ago $63.18 earnedSUPERMAN Drops, Disney Cuts WOKENESS? Hollywood DEI is DEAD | Friday Night Tights 333 Little Platoon

172K60 -

1:23:14

1:23:14

Talk Nerdy 2 Us

12 hours agoSpecial Guest - Next UFC Superstar - Dani Aleksovska

82.2K -

1:02:40

1:02:40

Man in America

14 hours agoThe Elites Are Losing Their War on Our Children w/ Robert Bortins

38.5K13 -

3:30:43

3:30:43

I_Came_With_Fire_Podcast

16 hours agoGovt' Shutdowns, VA Scandals, MORE Drones, Syrian Strikes and staged rescues , and The DHS!

116K22 -

56:55

56:55

The StoneZONE with Roger Stone

11 hours agoTrump Should Sue Billionaire Governor JB Pritzker for Calling Him a Rapist | The StoneZONE

88.2K11 -

59:21

59:21

Adam Does Movies

11 hours ago $2.56 earnedMore Reboots + A Good Netflix Movie + Disney Live-Action Rant - LIVE

55.9K2 -

36:28

36:28

TheTapeLibrary

20 hours ago $12.19 earnedThe Disturbing True Horror of the Hexham Heads

80.1K8 -

6:08:00

6:08:00

JdaDelete

1 day ago $7.57 earnedHalo MCC with the Rumble Spartans 💥

58.4K7