Premium Only Content

Process of making soccer balls. Korean best soccer ball making factory

Certainly! Let's delve into the fascinating process of making soccer balls, with a focus on the renowned Korean soccer ball manufacturing industry.

## The Art of Crafting Soccer Balls: A Korean Perspective

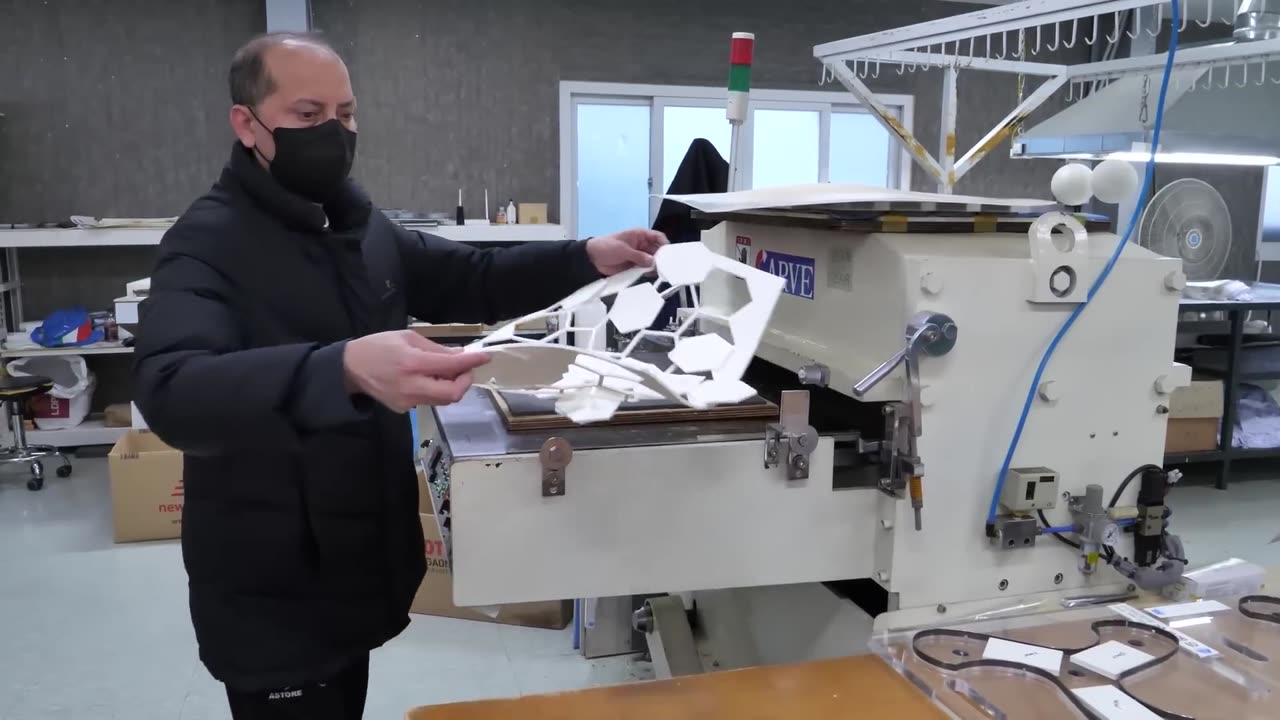

### 1. **Cutting the Panels**

The journey begins with cutting the panels that will form the soccer ball. These panels are typically made from synthetic leather, a durable and water-resistant material. The precise shapes are meticulously crafted, ready to be stitched together.

### 2. **Sewing the Panels Together**

The heart of soccer ball production lies in the stitching process. Strong nylon threads weave the panels into a cohesive sphere. The intricate patterns ensure optimal aerodynamics and playability. The panels are carefully aligned, creating the iconic hexagonal and pentagonal design.

### 3. **Bladder Insertion**

Inside the stitched panels, a bladder finds its place. No longer made from actual pig bladders (thankfully!), modern soccer balls feature synthetic bladders. These bladders provide the ball's structure and maintain its shape. They are inflated to the desired pressure, ensuring consistent bounce and responsiveness.

### 4. **Layering and Lamination**

The outer panels are layered and laminated to enhance durability and performance. The layers may include additional synthetic materials or specialized coatings. The goal is to create a robust outer shell that can withstand intense play on various surfaces.

### 5. **Quality Control and Testing**

Korean factories meticulously inspect each ball. They check for symmetry, weight distribution, and overall quality. Rigorous testing ensures that the ball meets international standards. From circumference to rebound, every aspect is scrutinized.

### 6. **Design and Branding**

Soccer balls receive their unique designs, often reflecting the manufacturer's brand or sponsor. Vibrant colors, logos, and patterns are applied using advanced printing techniques. The final appearance is a blend of aesthetics and functionality.

### 7. **Packaging and Distribution**

Once perfected, the soccer balls are carefully packaged. They are ready to embark on their global journey, gracing professional stadiums, local fields, and passionate players' feet. Korean factories play a pivotal role in supplying high-quality balls to soccer enthusiasts worldwide.

## The Korean Best: Saka Soccer Balls

Among the top Korean soccer ball manufacturers, **Saka

-

LIVE

LIVE

Dr Disrespect

3 hours ago🔴LIVE - DR DISRESPECT - NEW PC VS. DELTA FORCE - MAX SETTINGS

4,330 watching -

1:24:15

1:24:15

The Quartering

2 hours agoRep. Swalwell's VIRAL Confrontation, Jeff Bezos Op-Ed Announcement, and Canada's Anti-Musk Campaign

9.2K5 -

1:22:57

1:22:57

Tucker Carlson

4 hours agoNancy Pelosi Stock Tracker Chris Josephs: How to Get Rich by Investing Like a Politician

47.5K15 -

2:59:34

2:59:34

Barry Cunningham

4 hours agoWATCH LIVE: DOGE SUBCOMMITTEE HEARING!

4.16K13 -

DVR

DVR

Simply Bitcoin

3 hours ago $0.71 earnedNEW REPORT PROVES This Bitcoin Bull Run is DIFFERENT!! | EP 1191

10K -

1:23:50

1:23:50

Russell Brand

4 hours agoAI Visions, War Deals, and the Next Big Lockdown? – SF544

72.4K14 -

1:18:31

1:18:31

vivafrei

5 hours agoCanadian Liberal Leadership Race TO THE BOTTOM! Florida Prosecutor Claims SELF DEFENSE? & MORE!

20.6K12 -

3:08:48

3:08:48

Right Side Broadcasting Network

6 hours agoLIVE REPLAY: President Trump Participates in First Cabinet Meeting - 2/26/25

86.6K25 -

1:57:29

1:57:29

The Charlie Kirk Show

2 hours agoJudges vs. The People + Is DOGE Enough? + Fort Knox | Rep. Roy, Glenn, Plume, Posobiec | 2.26.2025

48K7 -

2:39:35

2:39:35

The White House

4 hours agoPresident Trump Hosts First Cabinet Meeting, Feb. 26, 2025”

36.4K26