Premium Only Content

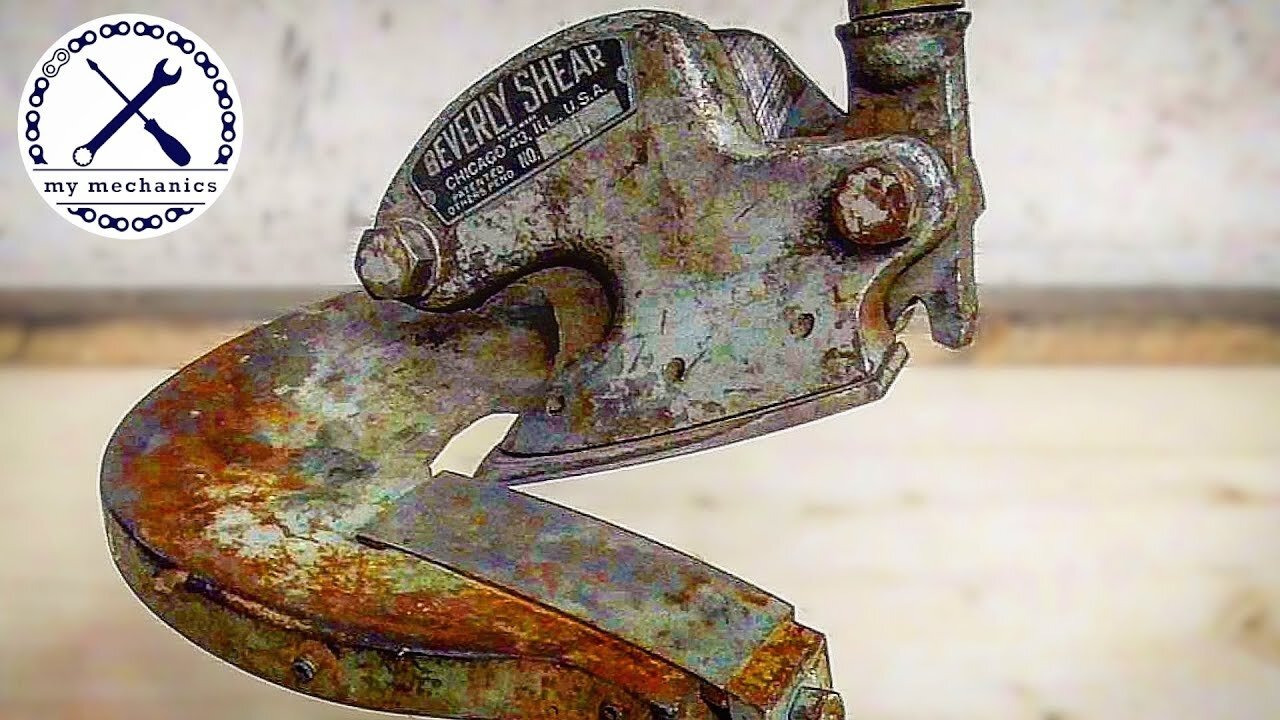

1930s Rusty Metal Shear - Perfect Restoration

SUBSCRIBE and check out my new Channel:

https://www.youtube.com/channel/UCM65z7cJmZUOpWUXVwHOc7g

1930s Rusty Metal Shear - Perfect Restoration

In this video I'm restoring a Beverly Shear model B1

My friend found this Beverly Shear in the steel waste at the recycling station. When I first saw this Beverly Shear I had no idea why it has such an unique shape. After a bit of research I quickly found out that this is a very well known tool. So I decided to restore it and bought it for $30. The Beverly Shear is a tool to cut sheet, because of it's unique shape it enables you to cut curved shapes and that's what makes the Beverly Shear so special. The Beverly Shear was invented by Kurt Nebel in 1931 in Chicago. There are 3 different sizes available: model B1, model B2 and model B3 which is the biggest one. They have made some changes over the years, but since 1947 the shears have remained virtually unchanged. For the color I decided to use a darker grey than the original and choose anthracide, I also added two washers. To make the parts black I used a bluing liquid called „Birchwood Casey - Super Blue“ and it worked very well. It's easy to handle and the big advantage over heating and quenching in oil is that you can do it without heating the parts up. So you won't change the structure of the steel and you can use it on hardened parts as well. Because I have no tools and experience in sharpening such blades, I decided to ask my friend Philipp Elsner from Elsener Messerschmied to do it. He's a professional knifemaker here in Rapperswil Switzerland. Check out his website, linked below. Overall I'm very happy how the Beverly Shear came out and as it is such a unique tool I'll keep it for myself.

I hope you like my work and the video.

Timestamps:

00:00 preview

00:38 testing

00:57 disassembling

03:45 showing all the parts

03:58 washing the parts

04:21 Removing paint with paint stripper

04:50 protecting the parts from rusting with Motorex MX50 oil spray

05:02 restoring the main part

06:49 restoring the front plate

08:18 restoring the back plate

09:09 restoring the two big bolts

09:50 restoring the nut

10:24 restoring the special washer

10:42 restoring the blade holding plate

11:21 making a new screw for the blade holding plate

12:32 polishing the new washer

12:44 assembling test

13:24 restoring and sharpening the blades

14:36 restoring the handle holder

15:39 restoring the handle and making a sleeve for it

17:54 restoring the screw for the handle

18:20 making a special washer on the lathe

19:18 restoring the sign

19:44 showing the two new rivets for the sign

19:52 restoring the small screws

20:15 making the parts black with Birchwood Casey - Super Blue

21:04 masking the parts with aluminum tape for sandblasting

21:46 sandblasting

22:51 filling the holes with 2K filler

23:18 masking the parts for painting

23:27 applying 2K primer

23:36 applying 2K anthracide coat

24:07 showing all the parts before reassembling

24:23 reassembling

26:29 adjusting the blade distance

26:40 showing the finished product

27:36 final testing

27:57 cut comparison before/after

My camera:

Panasonic HC-V180

If you have any questions about the process, machines I'm using or other stuff, just ask me in the comments. I read them all and I try to reply as soon as possible.

Sorry for my bad English, it's not my language. I try my best to improve my technical English.

Subscribe for more of my content. I'm uploading videos about mechanical stuff, as new creations and buildings and also restorations.

Thank you for watching

My Patreon Page:

https://www.patreon.com/mymechanics727

-

LIVE

LIVE

TheSaf3Hav3n

2 hours agoCALL OF DUTY: BLACK OPS 6 | A QUIET PLACE: THE ROAD AHEAD | #RumbleTakeOver

587 watching -

LIVE

LIVE

TheNateVibez

1 hour agoOmni-🤖 - First Rumble Stream.🫡 - VETERAN

914 watching -

LIVE

LIVE

Tundra Gaming Live

6 hours ago $0.36 earnedThe Worlds Okayest War Thunder Stream//FORMER F-16 MAINTAINER//77th FS//#rumblefam

254 watching -

LIVE

LIVE

DemolitionDx

2 hours agoSunday night COD with friends.

686 watching -

2:10:14

2:10:14

vivafrei

12 hours agoEp. 237: More Trump Cabinet Picks! MAHA or Slap in the Face? Canada on Fire! Go Woke Go Broke & MORE

154K194 -

2:23:21

2:23:21

SOLTEKGG

2 hours ago $1.79 earned🟢 First Day on RUMBLE!

21.6K -

LIVE

LIVE

Vigilant News Network

6 hours agoCOVID-Vaccinated Hit With Grave New Reality | Media Blackout

2,331 watching -

1:26:31

1:26:31

Josh Pate's College Football Show

6 hours ago $1.59 earnedSEC Disaster Saturday | Major CFP Earthquake Coming | Officiating Is A Disaster | New Studio Debut

16.1K1 -

1:43:05

1:43:05

Adam Does Movies

9 hours ago $0.29 earnedGladiator II Spoiler Conversation With Hack The Movies

19.8K -

24:10

24:10

Bwian

9 hours agoI Don't Know What I'm Doing in Fortnite, But I Still Won...

15.6K1