Premium Only Content

Precision Forging for Aerospace | Friend Metals

Before forging starts, stainless steel is cleaned to remove impurities.

It’s shaped into a 'billet', a basic form that sets the stage for precision forging.

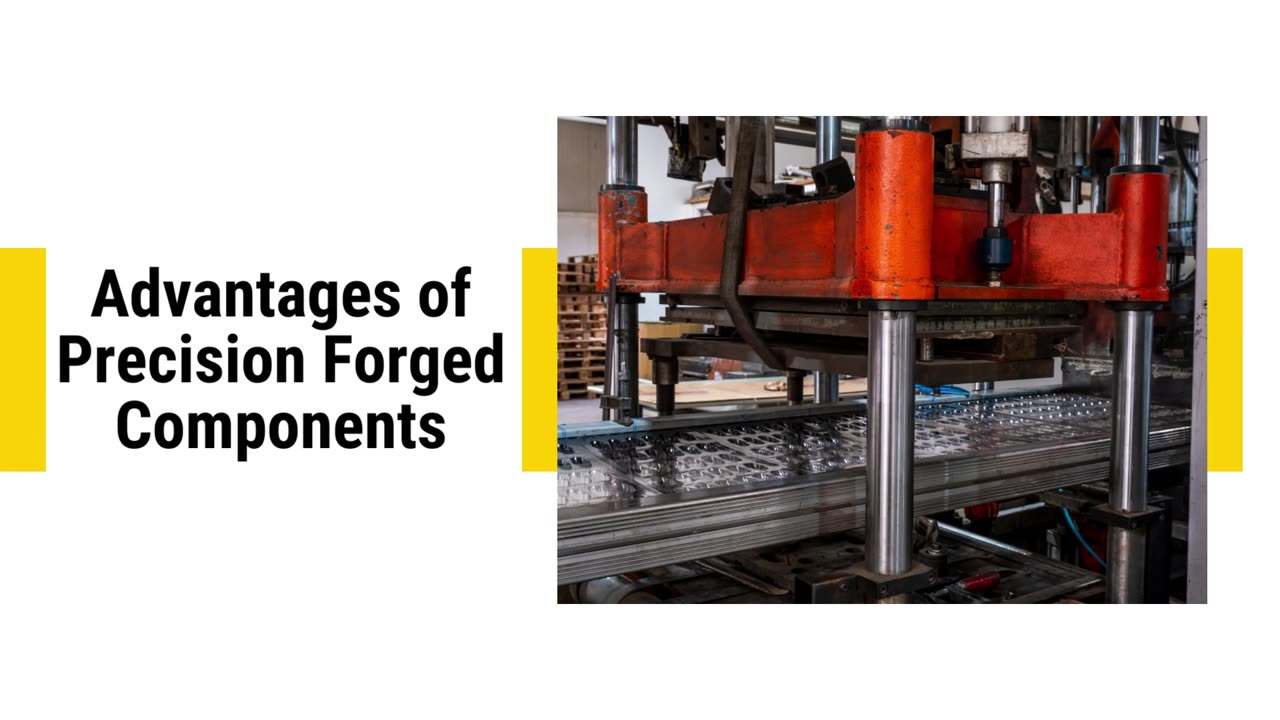

Advantages of Precision Forged Components

1.Reduced Material Wastage - Near-net-shape components mean less post-forging material removal.

2.Superior Surface Finish - Precision forging results in smoother components.

3.Consistent Microstructure - A uniform microstructure in the metal thanks to controlled techniques.

Challenges in Precision Forging

1.Ensuring Material Integrity - High temperatures and pressures can introduce imperfections. Quality control is crucial.

2.Overcoming Complex Geometries - Aerospace parts have intricate designs. Crafting them accurately requires skill and advanced tooling.

3.Maintaining Tight Tolerances - The margin for error is tiny. Precision is paramount.

4.Cost Implications - Precision forging minimizes wastage but requires a high initial investment.

For a deeper dive, visit: https://friendmetals.com/precision-forging-stainless-steel-components-for-aerospace/

-

1:03:32

1:03:32

Winston Marshall

3 days ago"War On Children!" The DEMISE Of The West Starts With Schools - Katharine Birbalsingh

73.6K60 -

48:02

48:02

Survive History

9 hours ago $1.67 earnedCould You Survive as a Sharpshooter in the Napoleonic Wars?

21.1K1 -

12:03

12:03

Space Ice

9 hours agoSteven Seagal's China Salesman - Mike Tyson Knocks Him Out - Worst Movie Ever

13.4K13 -

11:37

11:37

Degenerate Jay

9 hours ago $1.60 earnedJames Bond Needs Quality Over Quantity From Amazon

12.5K2 -

15:23

15:23

Misha Petrov

9 hours agoTrad Wives & Girl Bosses Go to WAR!

14K31 -

2:03:11

2:03:11

TheDozenPodcast

7 hours agoFootball villain fighting the state: Joey Barton

15.4K -

LIVE

LIVE

Scottish Viking Gaming

10 hours ago💚Rumble :|: Sunday Funday :|: Smash the Blerps and Vape the Terpes

594 watching -

1:45:00

1:45:00

RG_GerkClan

12 hours ago🔴LIVE Sunday Special - It's Time for World Domination - Civilization VII - Gerk Clan

66.1K27 -

LIVE

LIVE

Major League Fishing

4 days agoLIVE Tackle Warehouse Invitationals, Stop 1, Day 3

142 watching -

23:34

23:34

marcushouse

13 hours ago $17.90 earnedBREAKING: Starship Launch IMMINENT – But What’s This SURPRISE Flight 9 Plan?! 🚀🔥

110K11