Premium Only Content

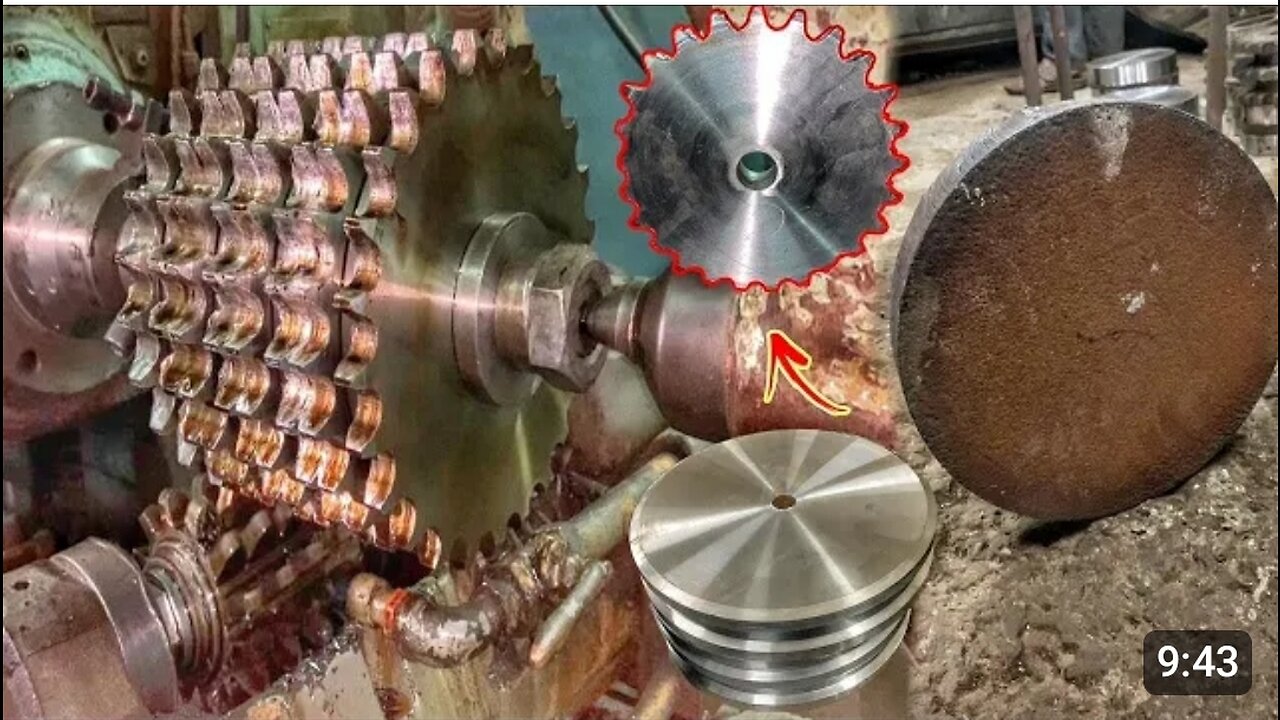

PROCESS OF MOTERBICK FRONT SPOCKET MANUFACTURING | PAK INFORMATION TECH

PROCESS OF MOTERBICK FRONT SPOCKET MANUFACTURING | PAK INFORMATION TECH

#moterbikes #motercycle #manufacturing #tool#pakinformationtech #viral #allah #making #process #technicalinformation #factory #spocket #fastenermanufacturing

Sprockets

motorcycle parts

auto parts

how its made

Manufacturing of Motorcycle Front Sprocket

sprocket manufacturing process

sprocket manufacturing

manufacturing rear wheel sprocket

sprocket,sprockets

chain sprocket

sprocket making

motorcycle sprocket change

sprocket production

front sprocket

manufacturing rear wheel sprocke,motorcycle sprocket combination

manufacturing process

how sprocket are manufactured

rear sprocket

manufacturing,manufacturing process of rear wheel sprocket

rear wheel sprocket

motorcycle front sprocket

sprocket making

sprocket

sprocket manufacturing process

chain sprocket

sprockets

sprocket production

motorcycle sprocket change

sprocket manufacturing

motorcycle front sprocket

manufacturing rear wheel sprocket

front sprocket

rear sprocket

motorcycle sprocket combination

rear wheel sprocket

rear sprocket change motorcycle

install rear sprocket

production of sprocket

making sprocket

how sprocket are manufactured

front sprocket making

Manufacturing a motorcycle front sprocket involves various steps and processes. Here's a simplified overview of how it can be done:

1. **Design and Prototyping**: Begin by designing the front sprocket. Use computer-aided design (CAD) software to create precise specifications. Prototyping may involve 3D printing or machining a sample sprocket for testing.

2. **Material Selection**: Choose the appropriate material for the sprocket. Common materials include steel, aluminum, or even composite materials. The choice depends on factors like strength, weight, and cost.

3. **Material Preparation**: Prepare the chosen material in the form required for manufacturing, typically in the shape of a round or flat stock.

4. **Cutting and Shaping**: Use various machining processes like milling, turning, or laser cutting to shape the sprocket from the prepared material. This step involves cutting teeth into the sprocket and creating the central mounting hole.

5. **Heat Treatment**: Heat treat the sprocket to increase its hardness and durability. This often involves processes like quenching and tempering.

6. **Surface Finishing**: Apply surface treatments, such as polishing or coating, to improve the sprocket's appearance and corrosion resistance.

7. **Quality Control**: Conduct quality checks and inspections at various stages of production to ensure that each sprocket meets the required specifications and standards.

8. **Packaging and Distribution**: Once the sprockets pass quality control, package them for distribution. This may involve bulk packaging for manufacturers or retail packaging for consumers.

9. **Distribution**: Ship the manufactured sprockets to motorcycle manufacturers, distributors, or retailers.

It's important to note that manufacturing a motorcycle front sprocket involves precision engineering and specialized machinery. If you're considering starting such a manufacturing process, you'll need a well-equipped facility and expertise in materials, machining, and quality control. Additionally, compliance with safety and industry standards is crucial.

-

1:49:21

1:49:21

Film Threat

6 hours agoBEST AND WORST OF 2024 + SQUID GAME SEASON 2 | Film Threat Livecast

41K4 -

1:06:04

1:06:04

The Big Mig™

20 hours agoGlobal Finance Forum Powered By Genesis Gold Group

33.7K2 -

34:38

34:38

Tudor Dixon

5 hours agoThe Changing Landscape Between Tech and Politics with Mike Benz | The Tudor Dixon Podcast

25.7K3 -

2:23:58

2:23:58

Matt Kohrs

15 hours agoRumble's Stock Is EXPLODING!!! || The MK Show

82.4K6 -

1:57:47

1:57:47

LFA TV

18 hours agoBOMBSHELL FINAL REPORT: BIDEN ADMIN SUPPRESSED WUHAN LAB LEAK | LIVE FROM AMERICA 12.27.24 11am EST

48.6K6 -

43:07

43:07

Grant Stinchfield

4 hours ago $6.21 earnedWe Built it... China Controls it... Trump Will Take it Back!

26.1K8 -

35:05

35:05

Rethinking the Dollar

4 hours agoTime to Pay the Piper! Debt Refinance Crisis Coming in 2025

23.1K3 -

52:34

52:34

PMG

18 hours ago $4.66 earnedHannah Faulkner and Steve Friend | EXPOSE THE FBI CORRUPTION - KASH PATEL

21.1K10 -

2:58:58

2:58:58

Wendy Bell Radio

11 hours agoOn Day One

92.3K83 -

1:59:27

1:59:27

Jeff Ahern

7 hours ago $4.06 earnedFriday Freak out with Jeff Ahern (6am Pacific)

31.9K1