Premium Only Content

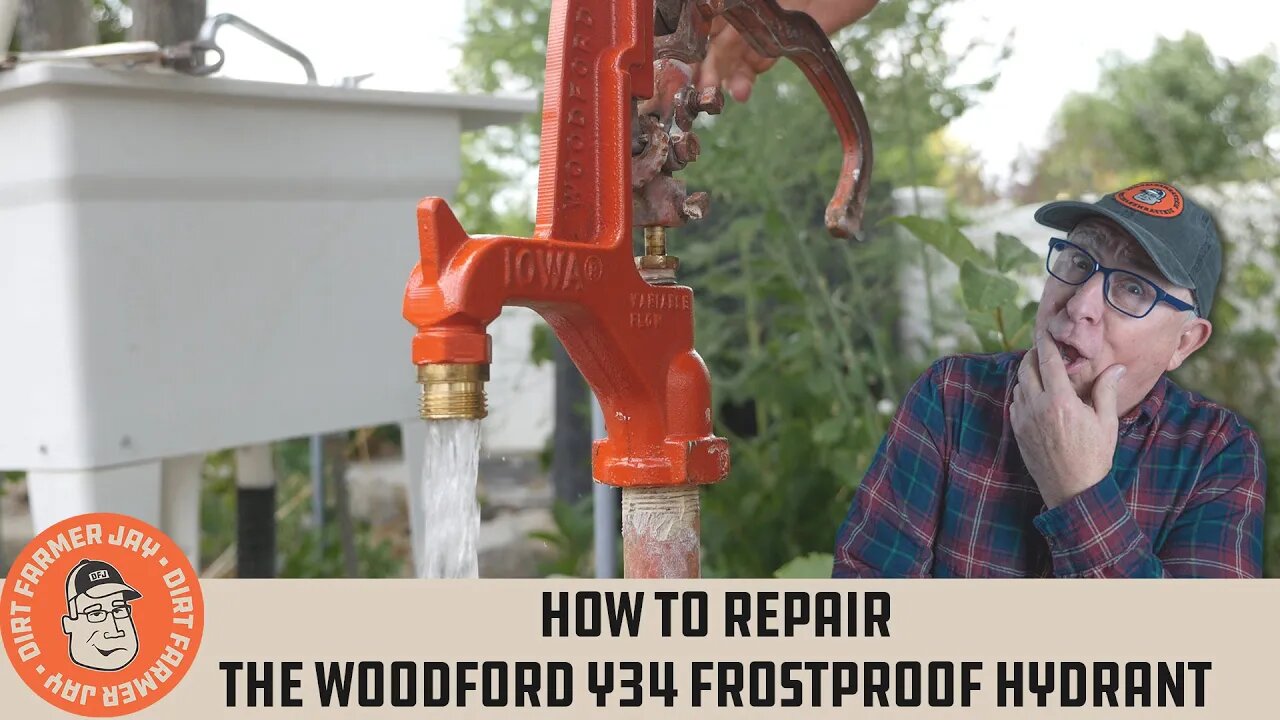

How to Repair the Woodford Y34 Frostproof Hydrant

When a frostproof hydrant develops a drip or won’t shut off completely, the repair is probably easier than you think! In the rare case that the cast head cracks, that’s an easy replacement too! We’ll show you!

#yardhydrant #frostprooffaucet #woodford

Most of the time for these types of yard hydrants, the repair isn’t a repair at all; it’s a simple adjustment! These durable devices are serviced up top at the handle, without digging anything up, except for VERY rare cases.

In this episode, we’ll show you both how to do adjustments to the faucet head, as well as replace the entire head. If the casting on the main faucet head is cracked (like ours), the top part of the faucet needs to be replaced. Even so, due to the ingenious design of these types of faucets, you WON’T have to dig up the faucet - all the work is done at the top of the unit. Spiffy, huh?

There are several manufacturers of frostproof yard hydrants, including Merrill Manufacturing® (www.merrillmfg.com), Woodford Manufacturing® (www.woodfordmfg.com), as well as Home Depot’s brand (Everbilt®), and Lowes ProPlumber®.

We were able to obtain replacement parts easily from Woodford Manufacturing. Simply visit their website at www.woodfordmfg.com to get started.

While they have different appearances and features (our Woodford® sports a handy adjuster for setting the “full-open” flow rate, as well as stopping accidental openings of the valve), they all operate using similar methods.

The valve body is located below the frost line in the soil. Various depths are available to suit your situation. The valve body is actuated by a pull rod that is attached to the handle. The valve is turned on and off using the handle that has an off-center cam that applies needed pressure to shut off the valve when the handle is in the off position.

In addition, the valve body is designed to drain water into the soil when the valve is shut off. This evacuates water from both the riser pipe (the pipe that extends from the valve body up to the handle/spigot assembly) and the valve body itself. This all but eliminates the possibility of freezing the valve, rendering it inoperable, as well as splitting the riser in freezing temperatures.

If your valve starts dripping or won’t shut off properly, the odds are highly in your favor that all that is needed is an adjustment of the pull rod to allow it to close more. WARNING! Be sure to turn off the water to your valve before making this adjustment or you will “enjoy” a flood of water!

Here are the basic steps to adjusting the pull rod

Here are the basic steps to replacing the cast head of the Woodford® Hydrant:

Have these tools and supplies on hand: two large pipe wrenches, an adjustable wrench, pipe compound or plumbing tape, and a flat-blade screwdriver.

Turn off the water supply and open the hydrant using the lever.

Loosen the cam and clevis assembly with the adjustable wrench.

Loosen the packing nut using the same wrench.

Use the two large pipe wrenches, in an opposing grip, one on the riser pipe and the other on the main cast faucet head.

Rotate the head counter-clockwise to remove it and the operating pipe assembly.

Separate the head and rod components. Inspect the components while the unit is disassembled, and service as needed.

Dig out the packing material using the flat-blade screwdriver. Make sure that no pieces of the packing material remain.

Put the bottom packing nut washer in the packing nut recess, then the packing material, then install and HAND-TIGHTEN the packing nut.

Place the operating assembly back into the riser pipe.

Clean the riser pipe threads and apply fresh pipe thread compound or plumbing tape

Slip the cast hydrant head down over the rod and through the packing material and nut, taking care to not damage the packing material.

Thread the faucet head casting onto the riser pipe and tighten properly by using the pipe wrenches in opposing grips on the faucet head and riser pipe and turning the head clockwise.

Turn the main water valve back on, and check for leaks. Tighten the packing nut only enough to stop leaking.

Enjoy your well-adjusted and durable yard hydrant!

If you’d like to see a repair overview video from Woodford Manufacturing, visit the link just below. You’ll learn 3 different procedures: 1.) Adjusting the pull rod to get the correct “snap” that will assure the valve is closed properly in the valve body below the frost line; 2.) How to remove and replace the plunger that operates within the valve body, and, 3.) how to remove, replace, and adjust the main cast head in case of damage or cracking.

https://www.youtube.com/watch?v=qmBpNz5wh6g

Sure, you can call a plumber to do this repair for you, but why? With what you’ve learned from Dirtfarmer Jay, you can JUST DO IT YOURSELF.

Follow us on Social Media to know when we’re building projects or releasing new episodes!

Instagram: https://www.instagram.com/dirtfarmerj

Facebook: https://www.facebook.com/dirtfarmerjay

-

LIVE

LIVE

tacetmort3m

20 hours ago🔴 LIVE - (MERRY CHRISTMAS) TIME TO SPREAD DEMOCRACY - HELLDIVERS 2 OMENS OF TYRANNY

53 watching -

12:42

12:42

Cooking with Gruel

18 hours agoBrown Butter Trifle with Salted Caramel and Cinnamon Apple

5.49K2 -

2:46

2:46

BIG NEM

7 hours agoDiscovering RAKIJA: The Holy Liquer of the Balkans

4.03K2 -

1:11:38

1:11:38

Film Threat

12 hours agoCHRISTMAS DAY CHILL STREAM WITH CHRIS GORE | Hollywood on the Rocks

127K24 -

14:22:40

14:22:40

The Quartering

1 day agoYule Log Christmas MAGA Edition With Memes! Come Hang Out!

218K29 -

38:41

38:41

MYLUNCHBREAK CHANNEL PAGE

1 day agoTimeline Begins in 1800? - Pt 1 & 2

98.7K49 -

1:23:41

1:23:41

Game On!

1 day ago $2.30 earnedNetflix NFL Christmas Games Preview and Predictions!

87.6K13 -

2:05:07

2:05:07

Darkhorse Podcast

1 day agoWhy Trump Wants Greenland: The 257th Evolutionary Lens with Bret Weinstein and Heather Heying

316K727 -

8:50:58

8:50:58

Right Side Broadcasting Network

1 day ago🎅 LIVE: Tracking Santa on Christmas Eve 2024 NORAD Santa Tracker 🎅

415K62 -

2:48

2:48

Steven Crowder

1 day agoCROWDER CLASSICS: What’s This? | Nightmare Before Kwanzaa (Nightmare Before Christmas Parody)

363K13