Premium Only Content

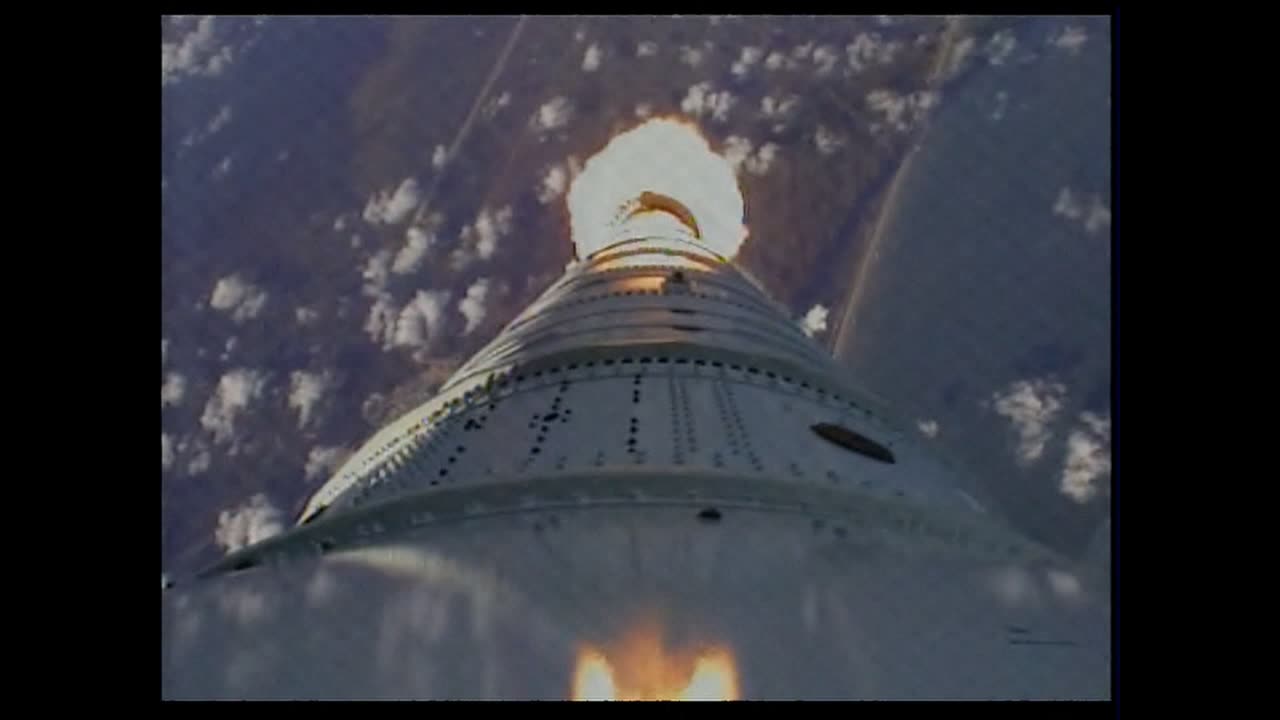

Ares I-X launch to Journey

Ares I-X was the first-stage prototype and design concept demonstrator of Ares I, a launch system for human spaceflight developed by the National Aeronautics and Space Administration (NASA). Ares I-X was successfully launched on October 28, 2009. The project cost was $445 million.

Ares I-X

Ares I-X before launch

Ares I-X launch

Launch

October 28, 2009, 15:30 UTC

Operator

NASA

Pad

Kennedy LC-39B

Outcome

Success

Apogee

c. 28 miles (45 km)

Launch duration

2 minutes

Components

First stage

4-segment SRB with a fifth segment mass simulator

Second stage

Upper stage simulator (USS)

Ares I-X insignia

The Ares I-X vehicle used in the test flight was similar in shape, mass, and size to the planned configuration of later Ares I vehicles, but had largely dissimilar internal hardware consisting of only one powered stage. Ares I vehicles were intended to launch Orion crew exploration vehicles. Along with the Ares V launch system and the Altair lunar lander, Ares I and Orion were part of NASA's Constellation program, which was developing spacecraft for U.S. human spaceflight after the Space Shuttle retirement.

Assembly Building (VAB) prior to rollout to Launch Complex 39B.

The RoCS modules were designed and constructed to fit into the Interstage segment of the USS by Teledyne Brown Engineering in Huntsville, Alabama.The engines were hot-fire tested at White Sands Test Facility in 2007 and 2008 to verify that they could perform the pulsing duty cycle required by Ares I-X.

Crew Module / Launch Abort System Simulator (CM/LAS Simulator)

Edit

At the top of the Ares I-X flight test vehicle was a combined Orion crew module and launch abort system simulator, resembling the structural and aerodynamic characteristics of Ares I. The full-scale crew module (CM) is approximately 16 feet (4.9 m) in diameter and 7 feet (2.1 m) tall, while the launch abort system (LAS) is 46 feet (14 m) long.

The CM/LAS simulator was built with high fidelity to ensure that its hardware components accurately reflect the shape and physical properties of the models used in computer analyses and wind tunnel tests. This precision enables NASA to compare CM/LAS flight performance with preflight predictions with high confidence. The CM/LAS simulator also helps verify analysis tools and techniques needed to further develop Ares I.[citation needed]

Ares I-X flight data were collected with sensors throughout the vehicle, including approximately 150 sensors in the CM/LAS simulator that recorded thermal, aerodynamic, acoustic, vibration and other data. Data were transmitted to the ground via telemetry and also stored in the First Stage Avionics Module (FSAM), located in the empty fifth segment.

Aerodynamic data collected from sensors in the CM/LAS contribute to measurements of vehicle acceleration and angle of attack.[6]: 9 How the tip of the rocket slices through the atmosphere is important because that determines the flow of air over the entire vehicle.

The CM/LAS splashed down in the ocean along with the upper-stage simulator (USS) after the boost phase of the mission.

This simulator was designed and built by a government-industry team at Langley Research Center in Virginia. It was flown to Kennedy Space Center by C-5 transport and was the last piece of hardware stacked onto the rocket in the Vehicle Assembly Building.

Avionics

Edit

Avionics

Ares I-X used avionics hardware from the Atlas V Evolved Expendable Launch Vehicle (EELV) to control its flight. This hardware included the Fault Tolerant Inertial Navigation Unit (FTINU) and Redundant Rate Gyro Units (RRGUs), and cable harnesses. The first stage was controlled primarily by heritage hardware from existing Space Shuttle systems. A new electronics box, the Ascent Thrust Vector Controller (ATVC), acted as a translation tool to communicate commands from the Atlas-based flight computer to the solid rocket booster's thrust vector control system. The ATVC was the only new avionics box for the flight. All other components were existing or off-the-shelf units. Ares I-X also employed 720 thermal, acceleration, acoustic, and vibration sensors as part of its developmental flight instrumentation (DFI) to collect the data necessary for the mission. Some of this data was transmitted real-time via telemetry while the rest was stored in electronics boxes located in the First Stage Avionics Module (FSAM), located inside the hollow first-stage fifth segment.

The ground-based portion of the mission's avionics included a ground control, command, and communications (GC3) unit, which was installed on Mobile Launcher Platform-1 (MLP-1) for launch at Launch Complex 39B at Kennedy Space Center. The GC3 unit enabled the flight control system to interface with computers on the ground. The flight test vehicle flew autonomously and was controlled by the FTINU, located on the underside of the lower ballast plates of the upper-stage simulator (USS).

The avionics were developed by Lockheed-Martin of Denver, Colorado, a subcontractor to Jacobs Engineering of Huntsville, Alabama, and is managed by Marshall Space Flight Center in Huntsville, Alabama.

Commemorative payload

Edit

Three shoebox-size packages were affixed inside the fifth segment simulator of the first stage to carry:

Three DVDs with 60-second home videos recorded by the public and submitted through NASA's website.

3,500 flags to be distributed to Ares I-X team members.

Processing

Edit

Ground operations

Edit

Ares I-X at the Launch Pad

Ground operations include activities such as vehicle stacking, integration, rollout, and liftoff, while ground systems include vehicle interfaces and lightning protection. Several new procedures and hardware items were developed for Ares I-X, including:

A new, taller lightning protection system for Launch Complex 39B, which is taller than the existing tower used for Space Shuttle operations.

A Shuttle-era VAB Firing Room 1 was completely remodeled and updated with new computer hardware to support Constellation and dedicated as the Young-Crippen Firing Room named after astronauts John Young and Bob Crippen in September 2009

A new Mobile Launch (ML) gantry was constructed using universal connectors to allow commercial vehicles to launch using ML. ML was used in the test flight.

Several systems on the Crawler Transporter were updated

A platform inside the Vehicle Assembly Building was removed to allow the Ares I-X vehicle to fit and roll out.[citation needed]

A new vehicle stabilization system (VSS), which kept the vehicle from swaying on the launch pad after rollout. The VSS uses off-the-shelf hydraulic shock absorbers from the Monroe division of Tenneco, Inc.

Environmental control systems (ECS) regulated temperatures inside the VSS and fifth segment simulator to keep the avionics and ground crew cool.

The ECS interfaces to the rocket are “T-0” units, meaning they disconnected from the launch vehicle automatically when the countdown reached zero.[6]: 4

Ground operations and ground systems were handled by United Space Alliance and NASA personnel at Kennedy Space Center.

Systems engineering and integration

Edit

The Ares I-X Systems Engineering & Integration (SE&I) Office, managed by the NASA Langley Research Center, was responsible for integrating the vehicle's parts into a complete rocket and making sure they work together as a system to meet flight test objectives. SE&I was responsible for ensuring all components functioned collectively to satisfy primary and secondary mission objectives. Detailed management of system interfaces, mission level requirements, validation plans, and flight instrumentation management were key SE&I contributions. SE&I provided the structural, thermal and aerodynamic analyses for the overall system to allow the components to be designed and built. SE&I also managed the mass of the vehicle and developed the trajectory and the guidance, navigation, and control algorithms used for vehicle flight.

To complete these tasks, wind tunnel testing and computational fluid dynamics (CFD) were used to investigate forces acting on the vehicle in various phases of flight, including lift-off, ascent, stage separation and descent. Once the basic design was understood SE&I provided structural analyses for the system to assure the rocket would behave properly once it was integrated.

Schedule development, management and control was provided by ATK Schedule Analysts permanently located at the NASA Langley Research Center working through the TEAMS contract agreement between ATK and NASA Langley.

Flight test

Edit

October 27, 2009 (Launch attempt 1)

Edit

Ares I-X launches from LC-39B, 15:30 UTC, October 28, 2009. The dramatic yaw maneuver to clear the launch tower is evident in the photo.

Ares I-X had been scheduled for launch on October 27, 2009, the 48th anniversary of the first Saturn I launch. The launch attempt was delayed due to weather plus other last-minute concerns.The ground crew experienced difficulty removing a protective cover from an important nose-mounted five-port sensor package. A private watercraft had blundered into the restricted downrange safety zone and had to be chased away. Launching through the day's high cirrus clouds could have caused triboelectrification, potentially interfering with range safety communication and hampering the RSO's ability to issue the self-destruction command. Launch Director Ed Mango repeatedly delayed resumption of the countdown from the planned hold point at T-00:04:00. Ultimately, constraints of the 4-hour launch window, coupled with high clouds and other last-minute concerns, caused the mission to be scrubbed for the day at 15:20 UTC on October 27, 2009. Launch was rescheduled for a four-hour window opening at 12:00 UTC on October 28, 2009.[18][20]

-

LIVE

LIVE

Stephen Gardner

19 minutes ago🔥CNN PANICS over $5000 DOGE Dividend | Trump Orders bigger Audits

1,271 watching -

1:53:54

1:53:54

The White House

2 hours agoPresident Trump Holds a Press Conference with President Emmanuel Macron of France

12.4K9 -

1:48:31

1:48:31

The Officer Tatum

2 hours agoLIVE MSNBC DROPS HAMMER On Joy Reid as STAFFERS PANIC! + More Ep 67

18.1K13 -

59:36

59:36

Chad Prather

1 hour agoTRUMP TAPS DAN BONGINO TO HELP LEAD FBI - IT’S OVER FOR THE DEEP STATE!

13.1K10 -

LIVE

LIVE

Barry Cunningham

7 hours agoTRUMP DAILY BRIEFING: DAN BONGINO TO FBI | LIVE PRESS CONFERENCE WITH MACRON | DOGE MELTDOWN!

2,063 watching -

2:08:16

2:08:16

Mike Rowe

3 days agoTim Allen Loves The Ballet | The Way I Heard It with Mike Rowe

25.8K15 -

1:42:25

1:42:25

Russell Brand

6 hours agoWar, Wokeism & Wealth: The Forces Reshaping Our World – SF542

108K38 -

DVR

DVR

vivafrei

6 hours agoMadness in Ireland! The War on Women, Children and the Attempt to Silence Whistleblower Jana Lunden!

52.5K18 -

1:01:41

1:01:41

The Charlie Kirk Show

3 hours agoWhat Did YOU Do This Week? + German Elections | Sen. Scott, Sacks, McCarthy | 2.24.2025

80.3K24 -

2:15:49

2:15:49

Benny Johnson

4 hours ago🚨 New FBI Deputy Director Dan Bongino Speaking LIVE Right Now After SHOCK Trump, Kash Appointment

187K135