Premium Only Content

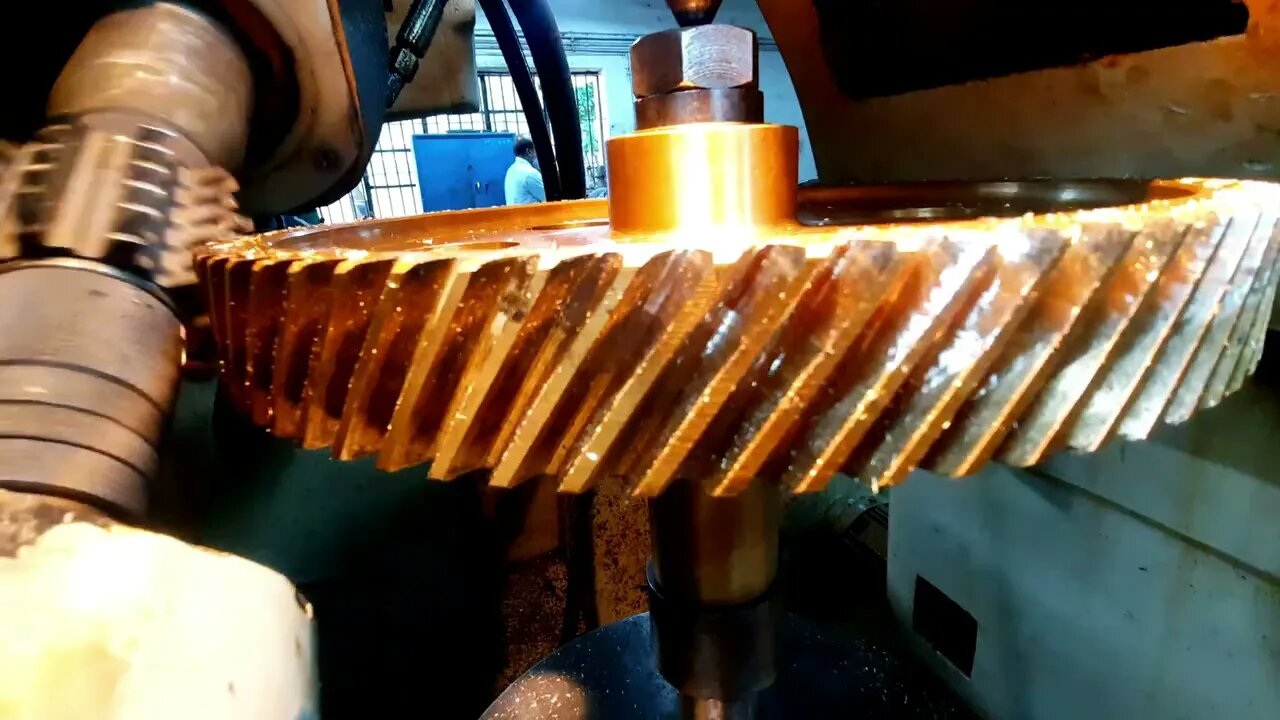

The Incredibly Advanced Gear Manufacturing Method That Could Change The Industry Forever

Production Processes of Helical Gear. The Incredibly Advanced Gear Manufacturing Method That Could Change The Industry Forever.

What is the manufacturing process of gear?

Gear manufacturing refers to the making of gears. Gears can be manufactured by a variety of processes, including casting, forging, extrusion, powder metallurgy, and blanking. As a general rule, however, machining is applied to achieve the final dimensions, shape and surface finish in the gear.

--------------------------------------------------------------------

Covered Points:

- Gears manufactur method.

- Hubbibg.

- milling.

- gashing.

--------------------------------------------------------------------------------------

Gear manufacturing refers to the making of gears. Gears can be manufactured by a variety of processes, including casting, forging, extrusion, powder metallurgy, and blanking. As a general rule, however, machining is applied to achieve the final dimensions, shape and surface finish in the gear. The initial operations that produce a semifinishing part ready for gear machining as referred to as blanking operations; the starting product in gear machining is called a gear blank.

In form milling, the cutter called a form cutter travels axially along the length of the gear tooth at the appropriate depth to produce the gear tooth. After each tooth is cut, the cutter is withdrawn, the gear blank is rotated, and the cutter proceeds to cut another tooth. The process continues until all teeth are cut.

Broaching can also be used to produce gear teeth and is particularly applicable to internal teeth. The process is rapid and produces fine surface finish with high dimensional accuracy. However, because broaches are expensive and a separate broach is required for each size of gear,this method is suitable mainly for high-quality production.

In gear form cutting, the cutting edge of the cutting tool has a shape identical with the shape of the space between the gear teeth. Two machining operations, milling and broaching can be employed to form cut gear teeth.

gear manufacturing methods,technology,industry,factory,technology industry,technology innovation institute,technology of the future,gear cutting,gear cutting services,gear cutting and manufacturing,gear cutting by milling,gear cutting company,gear cutting lathe,gear cutting process,gear cutting machine,machine design,machine operator job description,gear box,gear hobbing,factory,factory automation,

BE MY FRIEND:

📸Add me on Instagram: { https://www.instagram.com/najmulhp/ }

📕Add me on Facebook: { https://www.facebook.com/bdfuntus }

🧑💼Add me on LinkedIn: { https://bd.linkedin.com/in/md-najmul-hossain-254954104 }

Join this channel to get access to perks:

https://www.youtube.com/channel/UCnDW9gfKjVmkv-6yw9NITIw/join

BOUT MY CHANNEL:

Hi! I’m { Md Najmul Hossain }. On my channel, you will find { lathe /milling / cnc / hobbing / excavator / crane / dump truck / bulldozer and more technology video }. I love sharing [ Machine / Machine Working tips / DIY tricks / working video/ Crafts / How to make / Manufacturing video etc.] with you guys as I experience them myself.

Subscribe here to see more of my videos in your feed!

http://www.youtube.com/channel/UCnDW9gfKjVmkv-6yw9NITIw?sub_confirmation=1

Feel free to add me on Instagram/Facebook/Snapchat/Tiktok: { najmulhp }

#helicalgear #suppergear #gearmanufacturing #gearbox #amazingtechnology #gearboxassembly #restoration #repairing

-

1:50:10

1:50:10

Redacted News

3 hours agoBREAKING! DEMS PLAN TO BLOCK TRUMP FROM INAUGURATION, BIDEN TO RESIGN TO INSTALL HARRIS | REDACTED

80.5K56 -

4:10

4:10

SLS - Street League Skateboarding

1 day agoJhank Gonzalez 4th Place SLS Sydney 2024 | Best Tricks

23.6K -

1:12:52

1:12:52

Steve-O's Wild Ride! Podcast

11 days ago $3.10 earnedJay Mewes Is Using DNA Testing To Find His Family - Wild Ride #241

20.8K4 -

1:02:32

1:02:32

Criminal Content

1 day agoWITNESS (1985) Movie Reaction w/ Coby FIRST TIME WATCHING

4.93K1 -

47:11

47:11

PMG

4 hours ago"Hannah Faulkner and Seth Gruber | THE HOLOCAUST OF THE UNBORN"

100 -

1:01:45

1:01:45

In The Litter Box w/ Jewels & Catturd

1 day agoNo RINOs, Neocons, or Warhawks! | In the Litter Box w/ Jewels & Catturd – Ep. 688 – 11/11/2024

84.2K22 -

2:27:37

2:27:37

The Black and Jewish Podcast with Ashira Solomon

3 months agoEp. 3 Christians Are Biblically Illiterate

33K15 -

1:53:43

1:53:43

The Quartering

7 hours agoKamala's Desperate Attempt To Stop Trump & Installed As President! House Race Update New Border Czar

112K23 -

1:27:19

1:27:19

Russell Brand

7 hours agoKamala Goes BANKRUPT & WARS w/Biden + President Trump Announces Plan To RECLAIM Free Speech - SF490

244K325 -

11:32

11:32

Silver Dragons

5 hours agoIs This GAME OVER for SILVER?

27.7K13