Premium Only Content

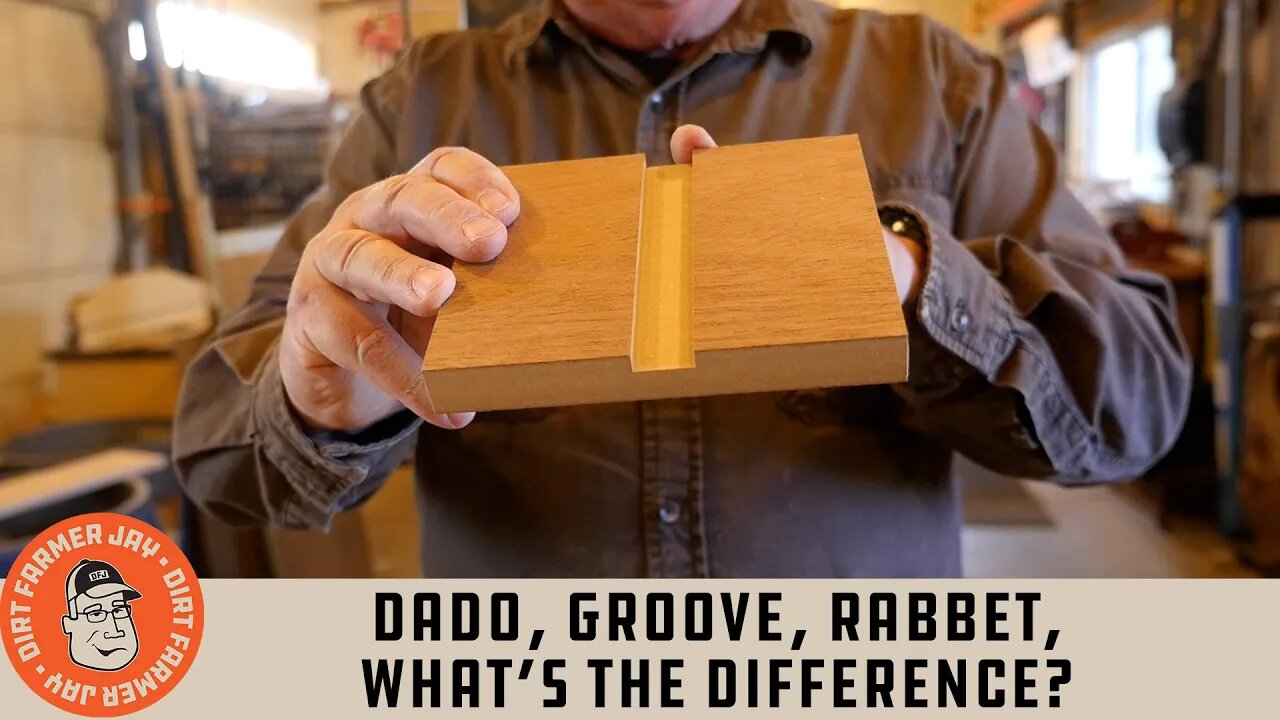

Dado, Groove, Rabbet, What’s the Difference?

Quick! What’s the difference between a dado, groove and rabbet? They are all related, but are defined differently and have different functions.

Buy your DFJ T-Shirt, Cap, or Coffee Mug at https.//www.dirtfarmerjay.com/shop

#woodworkingjoints #dadojoint #rabbetjoint

Whether you are a woodworker, maker, or tradesperson, using accurate vocabulary is important. Then you need to know how to make what you are describing, as well as know when that approach is best used.

As for dadoes, rabbets, and grooves (oh my! - with apologies to the Wizard of Oz), keeping them straight can be a challenge. The confusion is only added to as a dado blade is commonly used to cut all three. Even so, whatever blade is used is not what determines what the final cut is called.

Let's begin with a dado. A dado is a rectangular cut, with the sides typically perpendicular to the bottom. There can be exceptions to this, such as when components of a project are being joined to each other at an angle. Usually, the bottom of the cut is at a right angle to the sides. That leads to another attribute of a dado; it has two sides. Additionally, it runs across a panel, typically cross-grain, and perpendicular to the edges.

Next up is a groove. Like a dado, a groove has two sides and a bottom, and the sides, with the exception of angled components, are 90 degrees to the sides. What differentiates it from a dado is that it typically runs the “long” way of a panel, usually with the grain. A place where it is common to see grooves is when drawer bottoms are “let in” to the sides, front, and sometimes the back of the drawer box.

Last is the rabbet. While related to the other cuts/joints, it is different in that it only has two surfaces; the bottom and one side. And, while it can be across or with the grain, it is always located on the edge of a component. The rabbet both adds glue surface and helps register the joint during assembly.

The rabbet, groove, and dado can be cut with a variety of tools, and have been cut way before the advent of power tools. Historically, these joints were cut with specialized planes, or dedicated saws and chisels. There are some that still use these traditional approaches. For power tool users, these joints can be cut using a router or router table, a table saw with a dado head, cross-cut saws, or even circular saws with guides.

Whatever way you approach producing these foundational joints for woodworking and cabinet making, using the correct terminology, knowing when to use each one, and how to efficiently and accurately make rabbet, groove, and dado joints is a skill you’ll use over and over. Just Do It Yourself!

Buy your DFJ T-Shirt, Cap, or Coffee Mug at https.//www.dirtfarmerjay.com/shop

Follow us on Social Media to know when we’re building projects or releasing new episodes!

Instagram: https://www.instagram.com/dirtfarmerj

Facebook: https://www.facebook.com/dirtfarmerjay

You can help support this channel by buying our merchandise or supporting us on Throne or Patreon

-

LIVE

LIVE

BonginoReport

1 hour agoMainstream Media Plots The Next Plandemic! (Ep.02) - 03/11/2025

6,028 watching -

LIVE

LIVE

Michael Franzese

1 hour agoMegyn Kelly’s UNFILTERED Take on The Ukraine War, Trump & Modern Masculinity

1,363 watching -

1:43:21

1:43:21

Redacted News

2 hours agoBREAKING! UKRAINE AGREES TO CEASEFIRE WITH RUSSIA... BUT THERE'S A BIG CATCH | Redacted News

60.8K107 -

58:17

58:17

Candace Show Podcast

2 hours agoShould We Feel Bad For Blake Lively? | Candace Ep 157

31.3K47 -

LIVE

LIVE

The Nerd Realm

3 hours ago $6.73 earnedHollow Knight Voidheart Edition #19 | Nerd Realm Playthrough

320 watching -

1:17:27

1:17:27

Awaken With JP

6 hours agoThe Current Thing: Tesla Protesting - LIES Ep 82

61.7K30 -

1:07:08

1:07:08

Sean Unpaved

3 hours agoNFL Free Agency Rolls On! MLB Spring Training Heats Up along with 3x World Series Champ Dave Stewart

22.3K3 -

2:10:15

2:10:15

Right Side Broadcasting Network

8 hours agoLIVE REPLAY: White House Press Secretary Karoline Leavitt Holds Press Briefing - 3/11/25

117K33 -

2:06:00

2:06:00

The Quartering

6 hours agoTrump Goes NUCLEAR On Canada, Blasts Massie, Harry Potter Race Swap, Man Humiliated On TV Show

69.8K37 -

1:03:09

1:03:09

The White House

6 hours agoPress Secretary Karoline Leavitt Briefs Members of the Media, Mar. 11, 2025

74.5K52