Premium Only Content

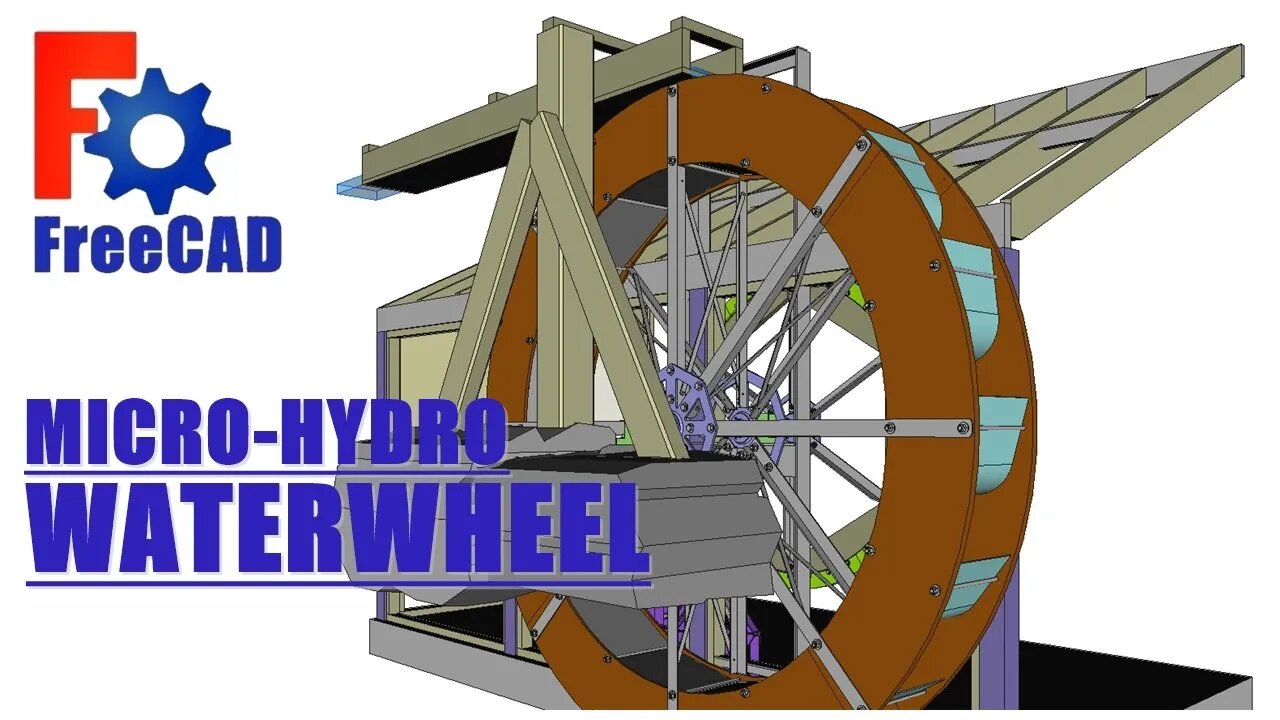

FreeCAD: Micro-Hydro Waterwheel

If you have 8'-12' head of water, a waterwheel maybe a good source of electricity. Small turbines will always be more efficient and be able to take greater advantage of the available energy resource.

But a well made waterwheel may have some advantages:

1. Aesthetics, there is a timelessness to the waterwheel.

2. Durability and ease of operation (vs the turbine).

This model is 8' diameter, and I imagine a flow of 5 gal/sec (0.02m3/s). Which produces 235 watts at 50% efficiency (from the Online Hydro Power Calculator). Not much, so gaining every bit of efficiency is important. The big pulley is to get the big jump in speed, then a second stage. A gearbox would be more efficient, but there is no flexibility to it, and in a possibly remote location basic is better.

The wheel I imagine being made of eight 12" bent composite deck boards sections cnc routed, same as the 6 sections of the big pulley. 3/16x2x1.5 angles, 5/16" plasma cut plate hub with weld-in bushing. The bucket backs are composite, the bucket fronts are light gage 12" aluminum, pushed into the slots.

The big pulley is fabricated the same way the wheel is. But the groove sections I think could be 3D printed and a twist-lock v-belt.

The shaft and all the hardware should be stainless. The big bearings? it turns so slow, a hardwood or solid bearing might be best (there goes the efficiency), it needs careful consideration (and a cover too).

I hope you enjoyed the video, thanks for watching.

-

2:03:50

2:03:50

vivafrei

8 hours agoElon CONFIRMS Biden Played Politics with Astronauts; JFK Files Dud? Trump Attacks Poilievre & MORE!

148K117 -

LIVE

LIVE

Dr Disrespect

8 hours ago🔴LIVE - DR DISRESPECT - WARZONE - 10 WINS IN A ROW EVENT

2,021 watching -

44:20

44:20

Candace Show Podcast

3 hours agoRyan Reynolds Wants to COME OUT… Of The Lawsuit | Candace Ep 163

86.1K53 -

LIVE

LIVE

LFA TV

1 day agoEurope: ‘To Avoid War, We Must Get Ready for War’ | TRUMPET DAILY 3.19.25 7PM

365 watching -

LIVE

LIVE

2 MIKES LIVE

3 hours ago2 MIKES LIVE #194 News Breakdown Wednesday!

163 watching -

10:05

10:05

Tundra Tactical

2 hours agoPam Bondi MISSES 2A Report Deadline!

5.91K2 -

21:52

21:52

AlaskanBallistics

17 hours ago $0.05 earnedFederal Terminal Ascent vs. Hornady ELD-X 6.5 Creedmoor

4.01K1 -

1:42:16

1:42:16

The Officer Tatum

4 hours agoLIVE Tesla Vandalism is the NEW J6 + MORE Officer Tatum Show EP 81

65.1K24 -

2:09:34

2:09:34

Darkhorse Podcast

7 hours agoDeportations, Doxxing, Measles Vaccine: 268th Evolutionary Lens with Bret Weinstein & Heather Heying

51.6K45 -

18:39

18:39

Revenge of the Cis

5 hours agoLocals Episode 201: Her

51.4K10