Premium Only Content

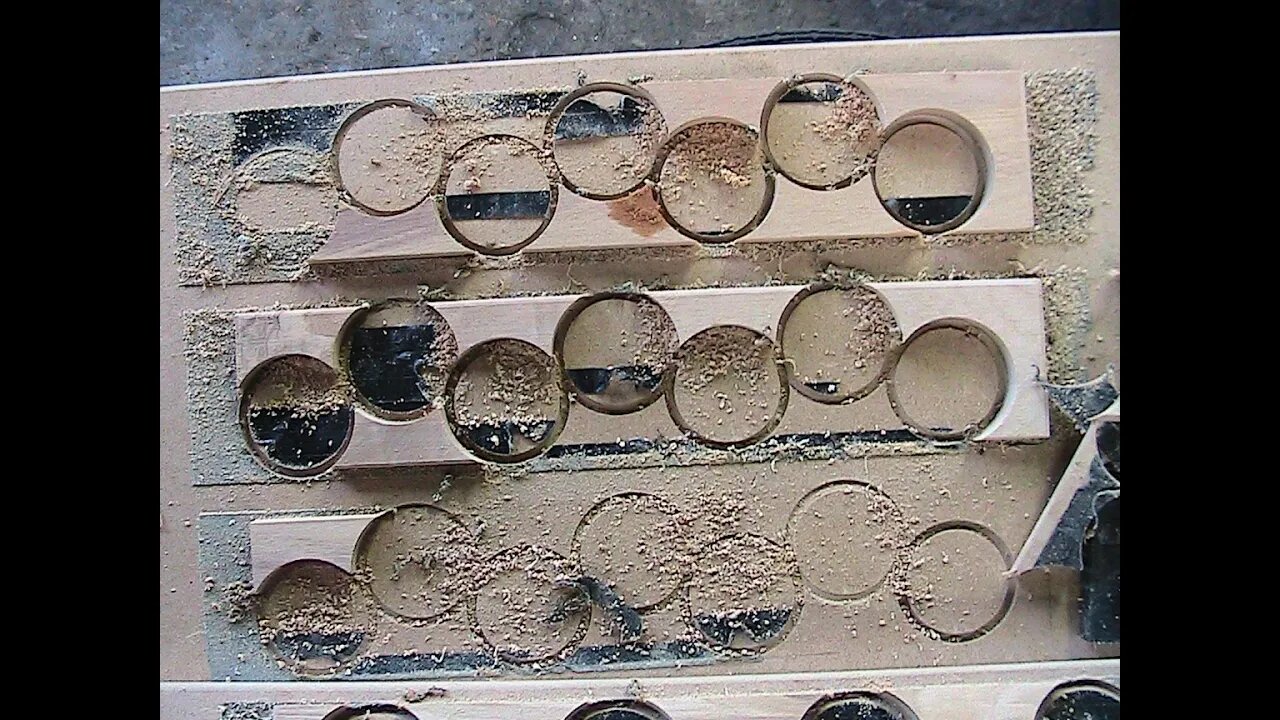

a unique work holding solution

Howdy YouTubers!

today we're taking a look at a unique situation. we have to make small wooden discs that can't have a hole in the center that would normally occur when using any kind of hole saw. they also need to have a smooth edge that a normal bi-metal hole saw can't deliver.

Bi-metal hole saws have a rubber ring on the arbor that allows a certain degree of movement of the tool while it is cutting. this gives the rough cut look of the finished piece. they also must have the center drill to keep the cutter centered in the work.

Carbide tipped hole saws have a rigid arbor, but also have the center drill to keep the cutter from drifting. since the finished product can't have any center holes the work has to be tied down in a manner that doesn't allow it to drift or wander during cutting operations.

We looked at using a plug cutter in a recent video, however due to manufacturing errors, that tool was ruled out from the get-go

#WorkHolding #Woodworking #UsingAHoleSaw

-

3:32

3:32

WTMJMilwaukee

3 years agoThe unique solution to Milwaukee's private ambulance shortage

7 -

18:54

18:54

The Rubin Report

9 hours agoHow One Woman Outsmarted Pornhub & Exposed Its Dark Secrets | Laila Mickelwait

111K92 -

LIVE

LIVE

Major League Fishing

5 days agoLIVE! - Bass Pro Tour: Stage 3 - Day 4

646 watching -

1:05:28

1:05:28

Sports Wars

11 hours agoLebron GOES OFF Over Bronny Hate, Pereira LOSES Belt To Ankalaev At UFC 313, Xavier Worthy Arrested

86.7K10 -

10:27

10:27

Tactical Advisor

1 day agoDMR or SPR for Civilian Use?

88.3K6 -

8:21

8:21

DEADBUGsays

1 day agoThe Crossbow Killer

85.8K13 -

8:40

8:40

Tundra Tactical

1 day ago $12.47 earnedThe Executive Order Wishlist.

93.2K6 -

7:22:52

7:22:52

SpartakusLIVE

1 day agoSaturday SPARTOON Solos to Start || Duos w/ StevieT Later

178K4 -

28:40

28:40

SLS - Street League Skateboarding

9 days agoTOP MOMENTS IN WOMEN’S SLS HISTORY! ALL THE 9’s - Rayssa Leal, Leticia Bufoni, Chloe Covell & more…

123K11 -

2:03:03

2:03:03

The Connect: With Johnny Mitchell

1 day ago $13.05 earnedHow Mexican & Chinese Cartels Control Illegal Marijuana Cultivation In America Using SLAVE Labor

87.3K25