Premium Only Content

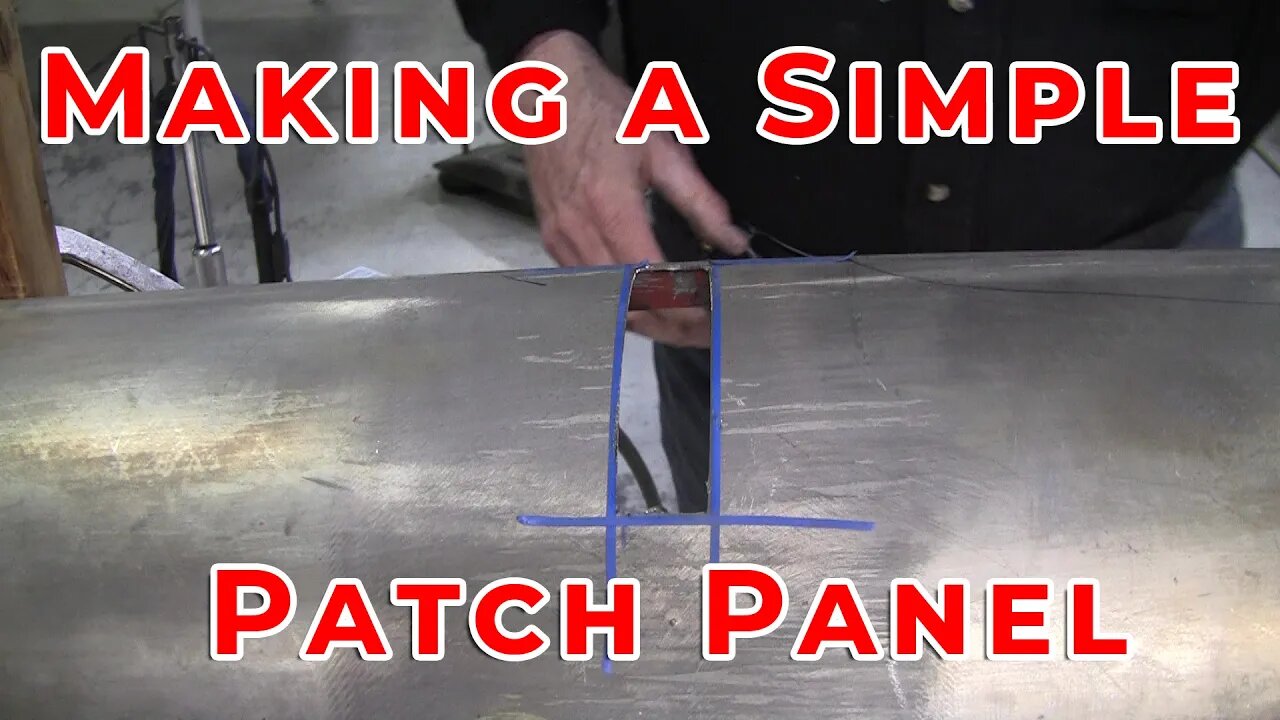

Metal Shaping for Beginners: Making a simple patch panel

https://www.proshaper.com

Our Amazon Storefront:

https://www.amazon.com/shop/proshaper

Making a simple patch panel.

This video has a little bit of everything. We have a Jaguar E-type fender that has some rust damage that needs to be removed. We dipped the fender in rust 911 for 24 hours, cleaned it up and are ready to patch the fender with a simple patch panel. Before Wray cuts out the rotted piece, he makes sure he knows how the panel flows by using a few gauges. Once he understands how it flows he cuts out the affected piece. Then he cuts out a square 20 gauge piece of sheet metal a little larger than the actual hole. He clamps the piece to the fender and marks the patch with a fine point pen, indicating the exact size needed to be cut. Wray cuts the piece and fits it to the fender and tac welds it. Once it's in place he finished welding the patch panel to the fender. Wray finds small amounts of distortion from the head so he uses his hammer and dolly to bring up any low spots. Then Wray takes the shrinking disc and runs it over the new patch panel ensuring the fender flows correctly. He then checks the fender with the gauges, making sure it's perfect and voila, the fender has been patched!

Email: Wray@Proshaper.com

Website: https://www.proshaper.com

Facebook: https://www.facebook.com/ProShaper/

Instagram: https://www.instagram.com/proshaper/

Twitter: https://twitter.com/ProshaperM

Linkedin: https://www.linkedin.com/company/proshaper

-

LIVE

LIVE

The Dan Bongino Show

2 hours agoAmerica's A-Team Hits The Ground Running (Ep. 2432) - 02/27/2025

129,212 watching -

LIVE

LIVE

The Rubin Report

53 minutes agoCNN Host Brutally Mocked for Trying to Profit Off of What He Called a ‘Conspiracy’

2,613 watching -

LIVE

LIVE

Benny Johnson

17 hours ago🚨BREAKING: Epstein List, Flight Logs RELEASED Any Minute By Trump | ELITES IN PANIC

9,333 watching -

LIVE

LIVE

Steven Crowder

2 hours ago🔴 Epstein File Watch & DOGE’s $17M Muppet Show Explained

45,918 watching -

1:04:22

1:04:22

Timcast

1 hour agoTrump Orders ALL TRANS MILITARY Discharged, Trans Person CAUGHT With BOMBS At Tesla Dealership

44.6K38 -

LIVE

LIVE

LFA TV

15 hours agoPAYBACK = JUSTICE! | LIVE FROM AMERICA 2.27.25 11AM

4,173 watching -

LIVE

LIVE

Bannons War Room

9 days agoWarRoom Live

21,545 watching -

2:17:39

2:17:39

Matt Kohrs

11 hours agoBREAKING MARKET NEWS: Bounce or Bust?! || The MK Show

21.1K1 -

47:26

47:26

BonginoReport

3 hours agoEpstein Files Drop Today-But How Much Will They Reveal? (Ep.149) - 02/27/2025

66.8K114 -

LIVE

LIVE

Wendy Bell Radio

6 hours agoThe Left Is Wrong About Everything

10,552 watching